Metal-porcelain dental root crown and method for manufacturing same

A technology of metal porcelain and a manufacturing method, which is applied to dentures and other directions, can solve the problems of long manufacturing cycle, broken porcelain teeth, low efficiency, etc., and achieves the effects of shortening the manufacturing cycle, restoring the chewing ability, and improving the manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

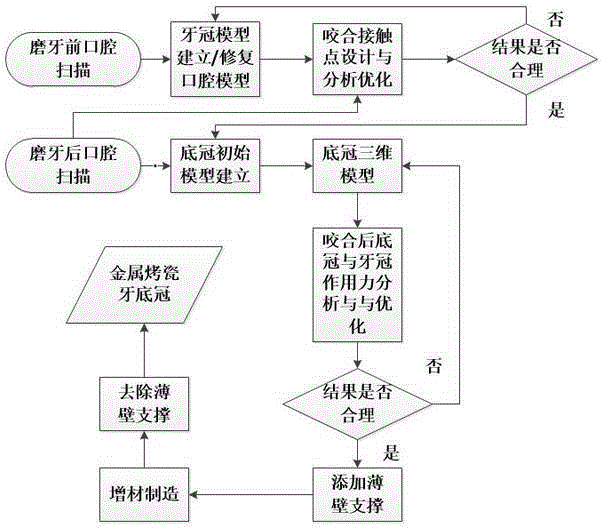

[0030] Combine below figure 2 A method of manufacturing a metal-ceramic dental crown will be described.

[0031] 1. Obtain patient oral data through reverse engineering, which is divided into two parts:

[0032] (1) Use CT to scan the patient's pre-molar oral cavity to obtain data on the occlusion of the oral cavity, including tooth shape, degree of tooth incompleteness, occlusal contact points, etc.; (2) Use CT to scan the patient's oral cavity data after molar, including post-molar teeth height and tooth shape.

[0033] 2. After obtaining the oral data, model the crown. The modeling process includes the restoration of the oral occlusal model, the restoration of the crown, the aesthetic design, the design of the occlusal contact point, and the matching of the gap between the original teeth in the oral cavity. Among them, the design of the occlusal contact point is an optimized design. After the modeling, the finite element technology is used for simulation optimization. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com