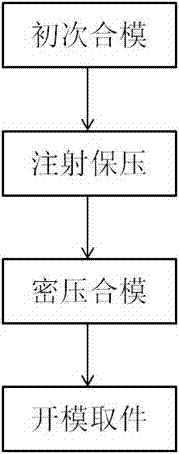

A kind of powder injection molding mold and using method thereof

A powder injection molding and injection molding technology, applied in the field of powder injection molding molds, can solve the problems of cumbersome steps and limited improvement in the compactness of powder molded products, and achieve the goal of improving compactness, density and compactness, and competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

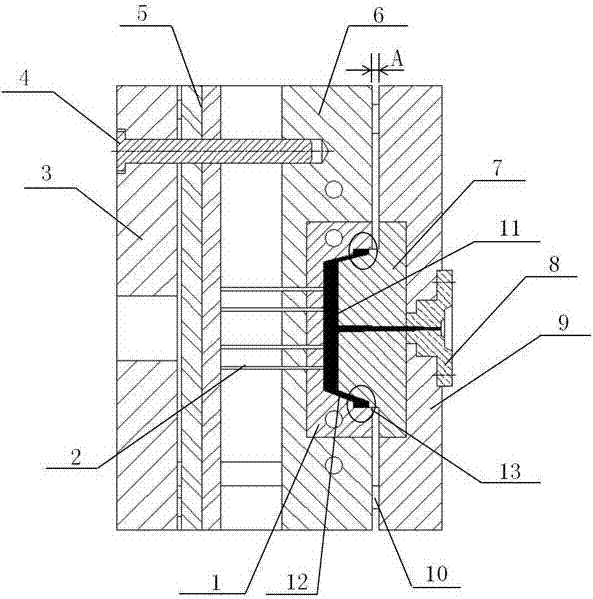

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] In this embodiment, the commonly used injection molding machine and supporting system in the powder metallurgy industry are used, and the particle size of the selected powder raw material is 10 μm on average, and the mold is installed on the injection molding machine. This part is the existing technology, that is, the commonly used technology in the industry, and will not be repeated here.

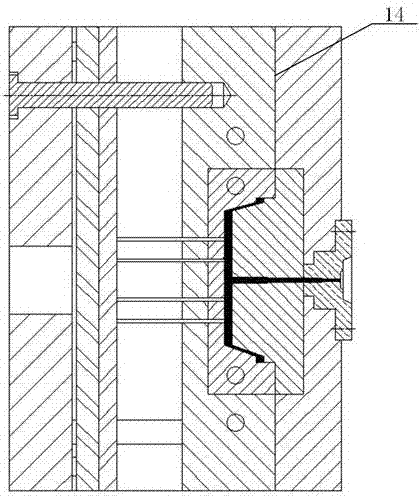

[0034] As shown in the drawings, the mold includes a movable mold 111 and a fixed mold 112 . The movable mold 111 includes a movable mold core 1, an ejector pin 2, a movable mold base plate 3, an ejector plate guide column 4, an ejector plate assembly 5, and a movable mold front plate 6. The fixed mold 112 includes a fixed mold core 7, a feed nozzle 8, and a fixed mold template 9. The movable mold 111 is connected with the fixed mold 112 through the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com