Grinding machine with automatic sudden stop function

An automatic and grinding machine technology, applied in the direction of grinding machine, grinding bed, grinding automatic control device, etc., can solve the problems of low work efficiency, waste of time, damage to the workpiece, etc., to improve production efficiency, high feed accuracy, processing high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

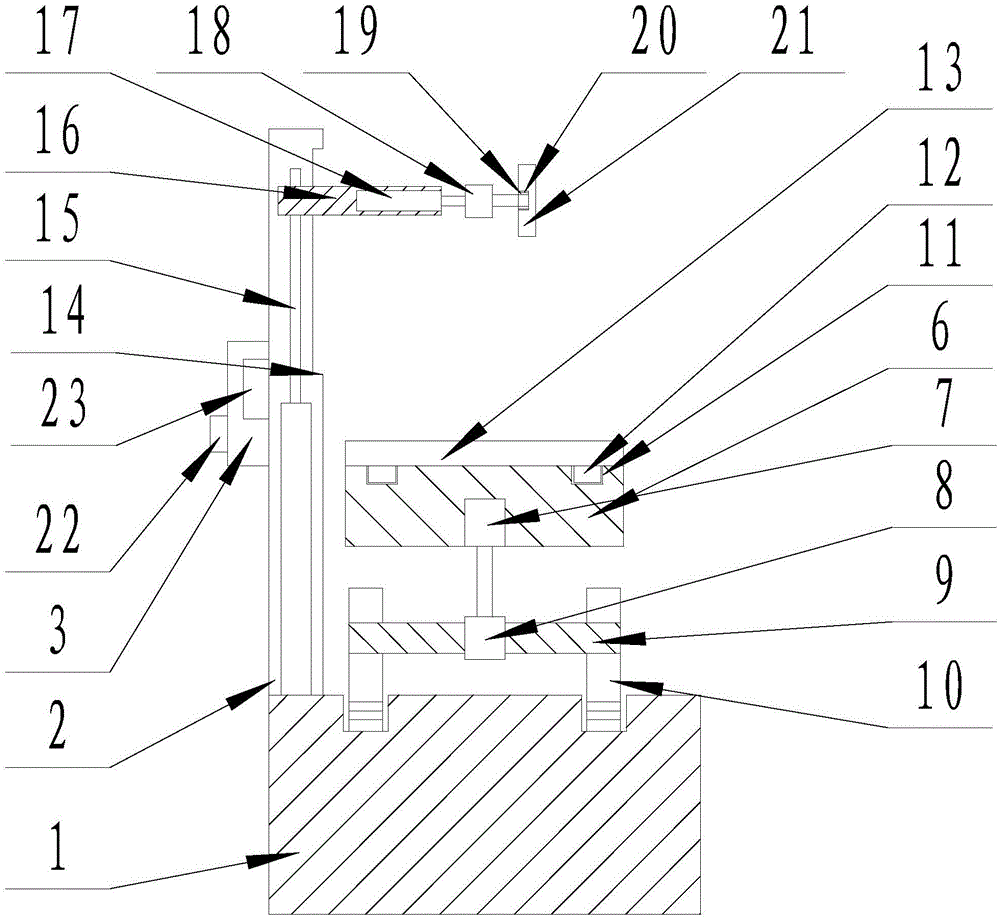

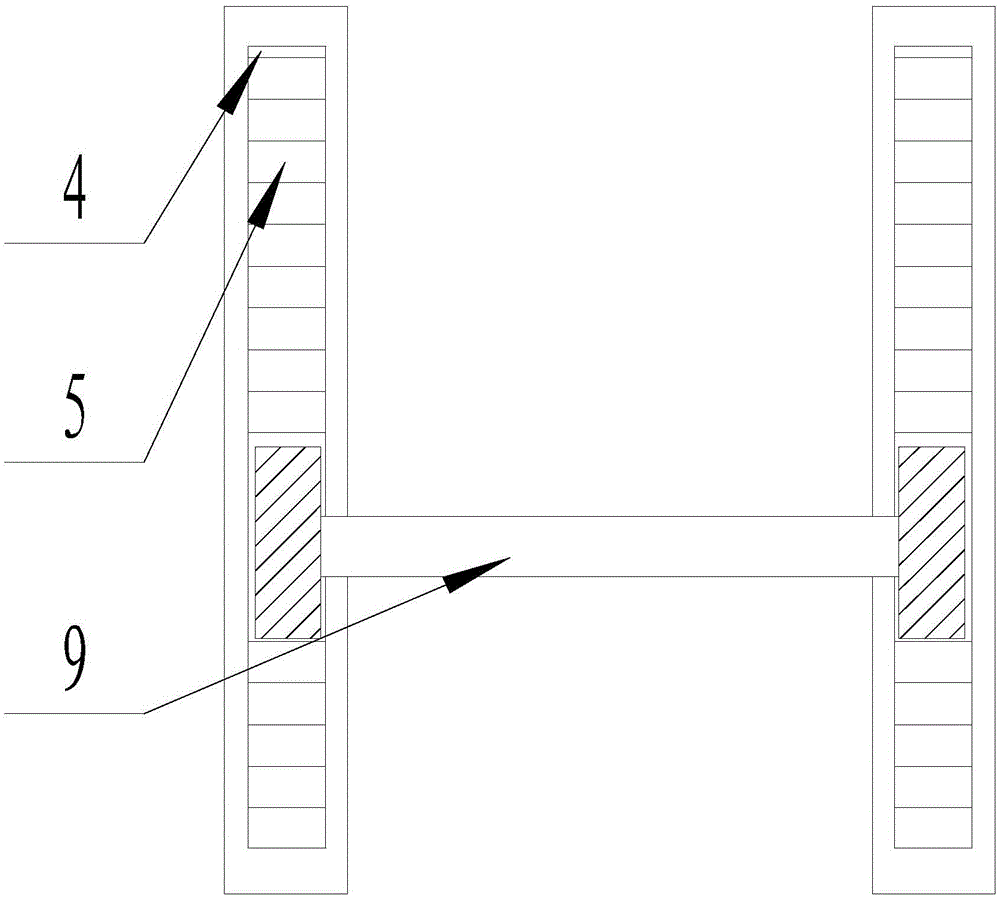

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a grinding machine capable of automatic emergency stop includes a rectangular bed (1), the rectangular bed (1) is fixedly installed on the ground, and the surface of the rectangular bed (1) is provided with a sliding The workbench mechanism, the sliding workbench mechanism is provided with an electromagnetic sucker clamping mechanism, the surface of the rectangular bed (1) is provided with a hollow column (2), and the hollow column (2) is vertically A feed telescopic mechanism is provided on the feed telescopic mechanism, and an automatic emergency stop sharpening mechanism perpendicular to it is provided on the feed telescopic mechanism, and a controller (3) is provided on the outer surface of the hollow column (2); the sliding The workbench mechanism consists of longitudinal guide rails (4) located on the upper surface of the bed (1), racks (5) loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com