Carving-molding all-in-one machine for rare metal

A rare metal and integrated machine technology, applied in the direction of metal processing equipment, welding equipment, laser welding equipment, etc., can solve the problems of inability to engrave in one piece, increase manual labor intensity, and prolong processing time, so as to reduce manual labor intensity and improve processing quality. The effect of high precision and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

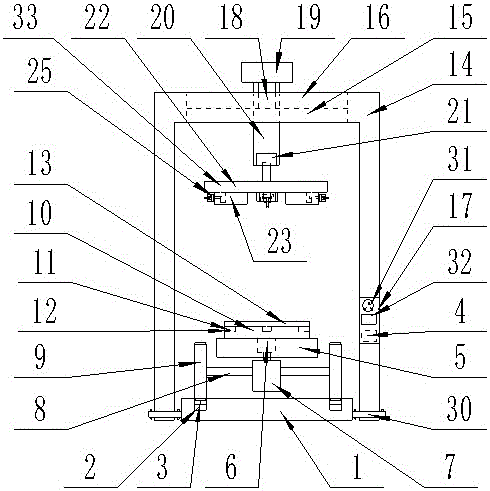

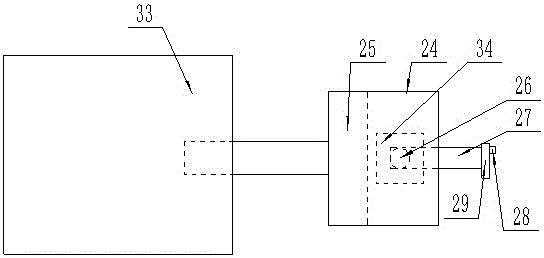

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a rare metal engraving and molding machine includes a base (1), the base (1) is fixedly installed on the ground, a movable rotary table mechanism is provided on the surface of the base (1), and the movable The mobile rotary table mechanism consists of a longitudinal guide rail (2) located on the upper surface of the base (1), a rack (3) located in the length direction on both sides of the longitudinal guide rail (2), and a rack located above the base (1). The rectangular workbench (5), the motor (6) fixedly installed in the workbench (5), the transmission mechanism (7) fixedly connected with the rotating end of the motor (6), and the transmission mechanism (7) are fixedly connected and positioned in the longitudinal direction The moving rod (8) between the slide rails (2), the gear (9) that is fixedly connected to both ends of the moving rod (8) and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com