Bamboo flake machine

A technology of deflagging machine and bamboo chips, which is applied in mechanical equipment, sugarcane machining, etc. It can solve the problems of increasing the manufacturing cost of bamboo products, affecting the process, and incomplete defrosting, so as to meet the requirements of reducing the thickness of bamboo chips and improving the uniformity of defatting. , the effect of expanding the thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

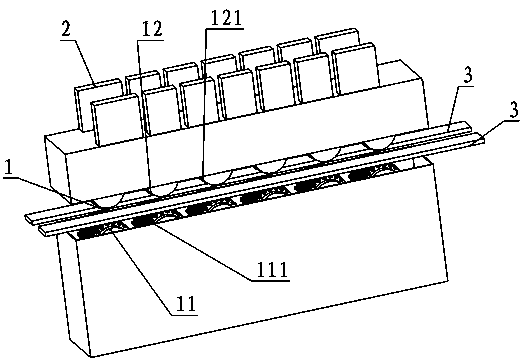

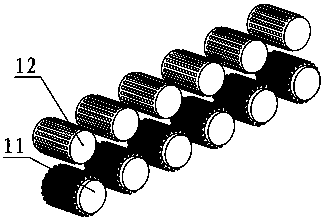

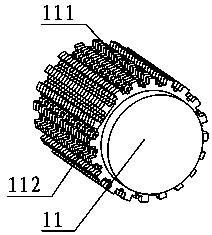

[0020] Such as figure 1 As shown, the bamboo flaking machine includes no less than five pairs of decomposing rollers 1, each pair of decomposing rollers 1 is provided with decomposing cutting rollers 11 and decomposing extrusion rollers 12 respectively arranged up and down, see figure 2 and image 3 , each pair of loosening and cutting rollers 11 of the pair of rolls 1 is provided with several circles of loosening blades 111, and each circle of loosening blades 111 is stepped along its circumference; see Figure 4 , and the outer surface of the disentangling squeeze roller 12 is provided with several spherical protrusion units 121 arranged in a ring around it. The bamboo ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com