Control method for injection molding machine

A technology of injection molding and control method, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of poor maintainability, excess cost, excess cost, etc., achieve miniaturization and light weight, easy maintenance work, and reduce excess cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

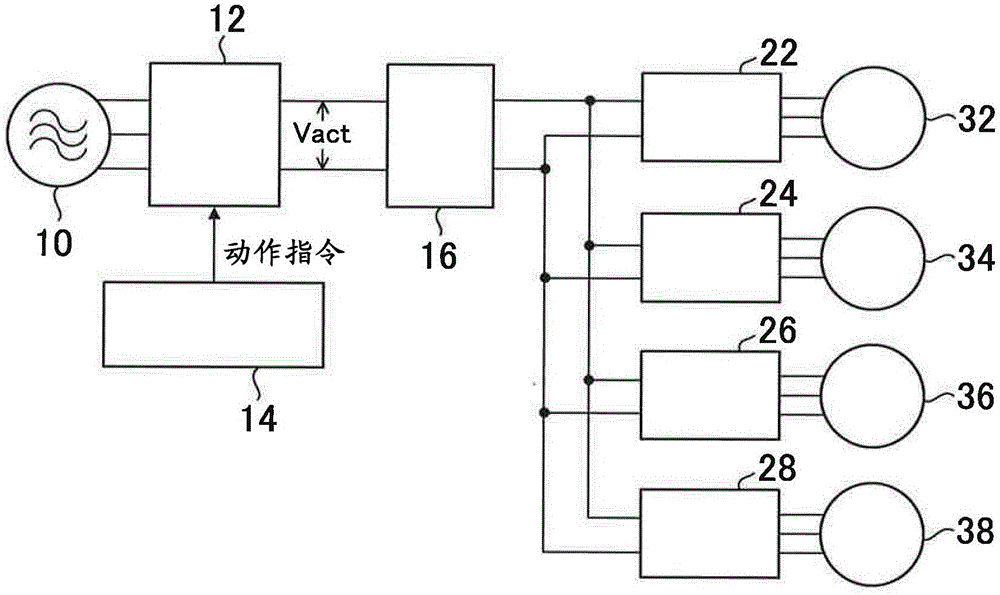

[0021] figure 1 It is a figure which shows the servomotor drive circuit of the injection molding machine of this embodiment. A power converter 12 is connected to the power supply unit 10. The power converter 12 is a device that converts the three-phase AC current and voltage supplied from the power supply unit 10 into a DC voltage. In addition, reference numeral 14 denotes a power converter control unit that issues operation commands to the power converter 12. The power storage unit 16 is connected to the power converter 12. In addition, in figure 1 Where Vact is the voltage of the power storage unit.

[0022] The voltage between the two lines connecting the power converter 12 and the power storage unit 16 is taken as the voltage of the power storage unit 16. In the present embodiment, the power storage unit 16 is composed of one or more power storage devices that are assembled and connected to the driving devices 22, 24, 26, 28 that drive various motors. Each drive device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com