A film-pressing and groove-pressing device applied to large-area and complex plastic-absorbing molds

A blister mold and large-area technology, which is applied in the field of film laminating devices, can solve the problems that the shape of the blister cannot be guaranteed and the mold utilization cannot be satisfied, and achieve the effect of increasing the working range, avoiding mutual jamming, and preventing easy scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

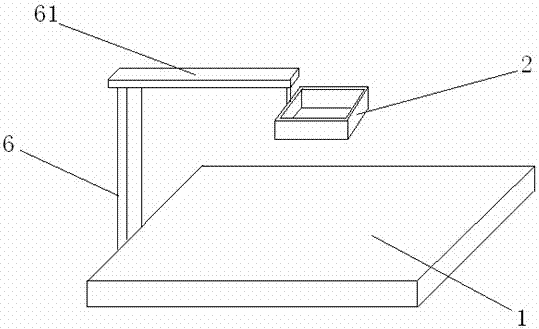

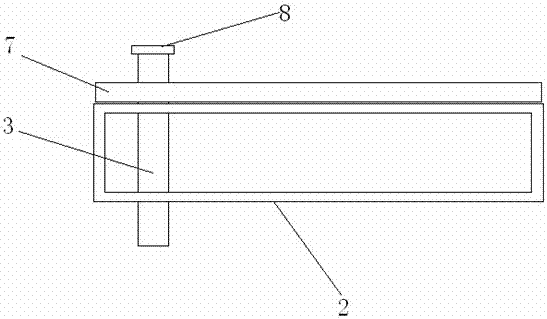

[0038] As shown in the figure, a film-pressing and grooving device applied to large-area and complex plastic-absorbing molds of the present invention includes a shaping device that can move up and down above the workbench 1 of the plastic-absorbing machine, and the shaping device includes The fixed frame 2 arranged horizontally, the specific shape of the fixed frame 2 can be set according to requirements, and can also be other shapes;

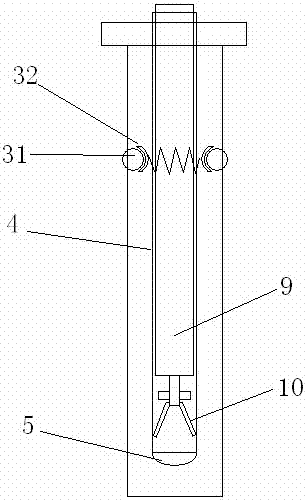

[0039] Several positioning rods 3 are vertically arranged in the fixed frame 2, and some positioning rods 3 are arranged horizontally and vertically in the fixed frame 2; A group of rolling balls 31, two rolling balls 31 are arranged in parallel, the rolling balls 31 are arranged through the rod wall, and are used to contact other positioning rods 3 outside to facilitate sliding, and a groove seat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com