Bucket elevator

A bucket elevator and cover technology, which is applied to conveyors, transportation and packaging, can solve problems such as belt tension reducing service life, backflow of materials in bucket elevators, and difficulty in feeding and unloading. The effect of improving the carrying efficiency, preventing slippage, and improving the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

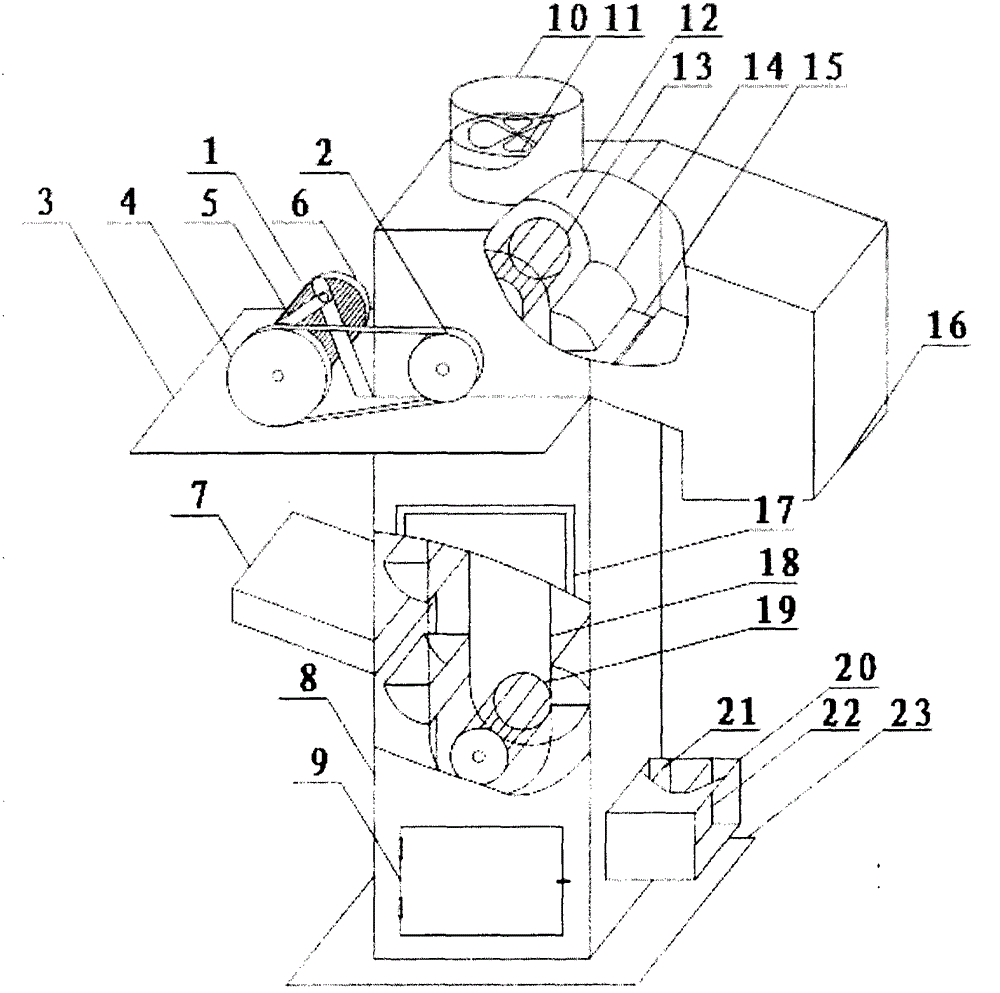

[0035] As shown in the accompanying drawings, a bucket elevator of this patent includes a drive device 1, an anti-reversal device 5, a traction device 12, a base 23, a casing 8, a support plate 3, a material blocking plate 15, and a feed port 7 And discharge port 16.

[0036] The driving device 1 includes a motor 6 and a driving wheel 4; the motor 6 is fixed on the support plate 3 and is connected to the driving wheel 4 through a shaft; the driving wheel 4 is connected to the driven wheel 2 through a belt; the driving device 1 is used to provide power to the traction device 12 The support plate 3 is arranged on the outer upper end of the casing 8 for supporting the driving device 1; the surface of the driving wheel 4 and the driven wheel 2 is provided with an anti-skid layer, and the anti-skid layer is an anti-skid layer bonded on the surface of the driving wheel 4 and the driven wheel 2 The anti-wear rubber cloth is used to improve the friction coefficient between the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com