A telescopic blade assembly and brake drum

A brake drum and blade technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve the problems of shortening the service life of drum brakes, affecting the cooling effect of the brake drum, and reducing the braking efficiency, so as to avoid the problem of brake drums. The effect of reducing dynamic performance, enhancing braking effect, and increasing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

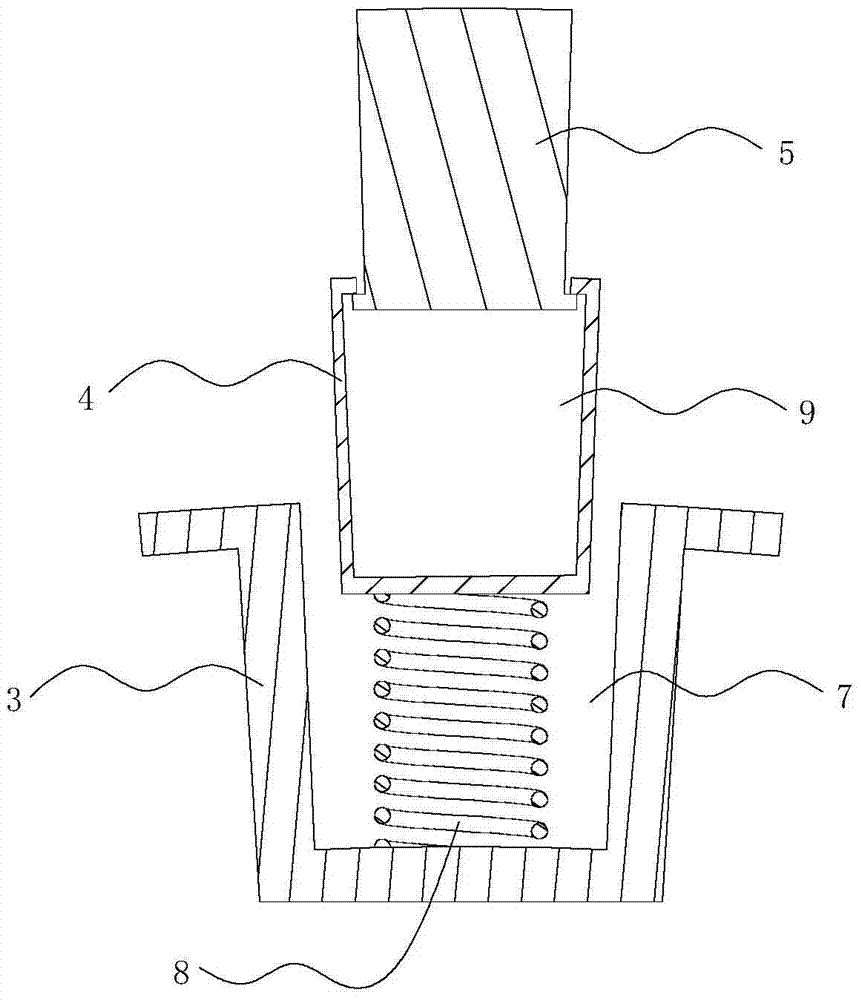

[0022] Embodiment 1, combining figure 1 , a telescopic blade assembly, the telescopic blade assembly includes a sliding seat 3, a blade seat 4 and a blade 5, the blade seat 4 is arranged in the sliding seat 3, the blade 5 is installed in the blade seat 4, and the blade 5 can extend out of the blade seat 4. The sliding seat 3 has a mounting groove 7, the blade seat 4 is located in the mounting groove 7, the bottom of the blade seat 4 is connected with the bottom of the mounting groove 7 through a return spring 8, and the opening of the sliding seat 3 has a fold that is turned outwards. side.

[0023] The inside of the blade holder 4 has a blade chamber 9 that can accommodate the blade 5. The blade 5 is located in the blade chamber 9 of the blade holder 4. The opening of the blade chamber 9 has a blocking portion that restricts the blade 5 from coming out. The blocking portion will block the blade 5. Make it impossible to break away from the blade cavity 9 completely. The ori...

Embodiment 2

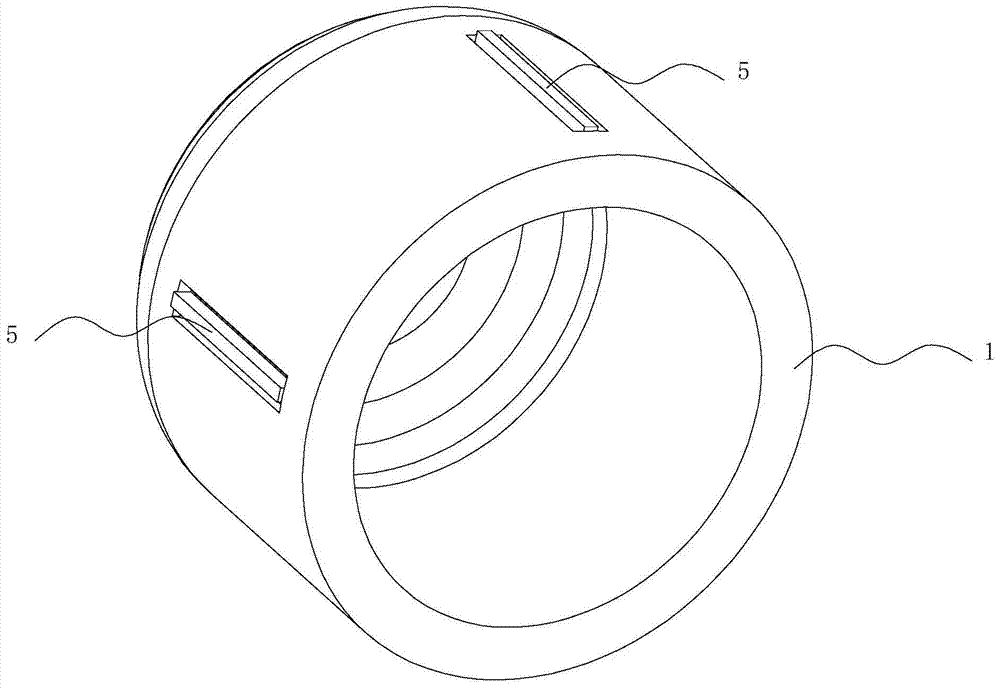

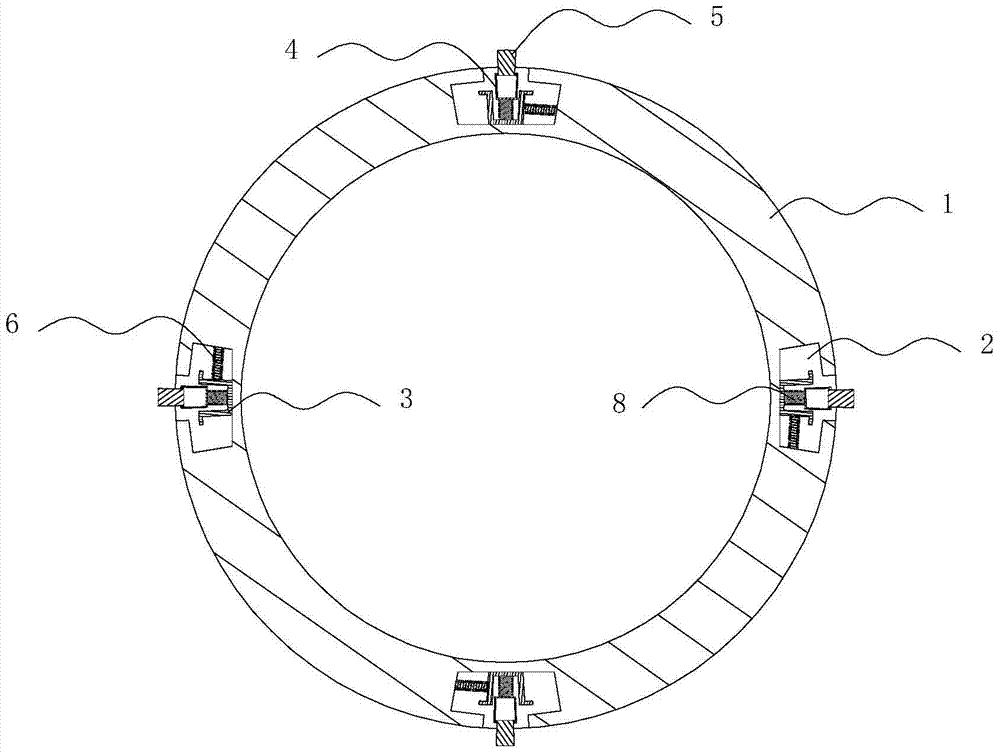

[0024] Example 2, combined with Figure 2 to Figure 4 , a brake drum, the annular outer wall of the brake drum 1 is evenly arranged with four accommodation cavities 2, the cross-section of all the accommodation cavities 2 is T-shaped, the openings of which are facing the outside of the brake drum 1. Each accommodating cavity 2 is provided with a telescopic vane assembly as described in Embodiment 1. The sliding seat 3 of the telescopic blade assembly is connected with the inner side wall of the accommodation chamber 2 through the telescopic spring 6, and the initial position of the sliding seat 3 is shown in Figure 4 , the sliding seat 3 is restricted on one side in the accommodation chamber 2 by the telescopic spring 6 , and the sliding seat 3 can slide in the accommodation chamber 2 . The orientation of the opening of the installation groove 7 and the orientation of the opening of the vane chamber 9 are the same as the orientation of the opening of the accommodating chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com