double involute gear

A double involute and involute technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of high center distance accuracy, difficult manufacturing, no separability, adaptability Sex and other issues, to achieve the effect of increasing the contact area, not easy to pitting failure, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

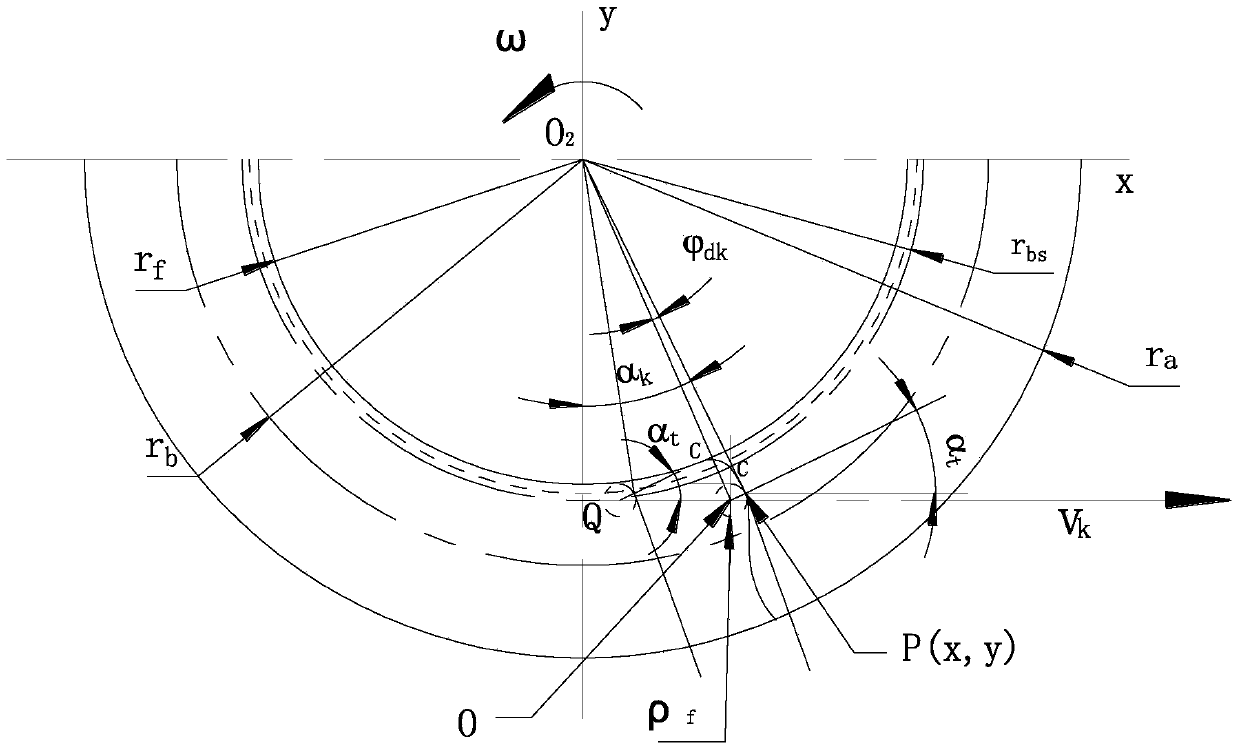

[0435] Embodiment 1: single large negative gear meshing transmission

[0436] The first-gear gear of the 6T53 automobile gearbox, the installation center distance is a=123, and the transmission ratio is required to be i=5. According to the calculation, actually determine the pinion z 1 =9, large gear z 2 =43, modulus m n =5, pressure angle α n =22.5°, helix angle β=8.1272222222° (8°7'38"). Specific gear and hob parameters are shown in Table 1~Table 2:

[0437] Table 1: Gear parameter table (single large negative gear transmission)

[0438]

[0439]

[0440] Table 2: Hob parameter table (big gear)

[0441] serial number

Embodiment 2

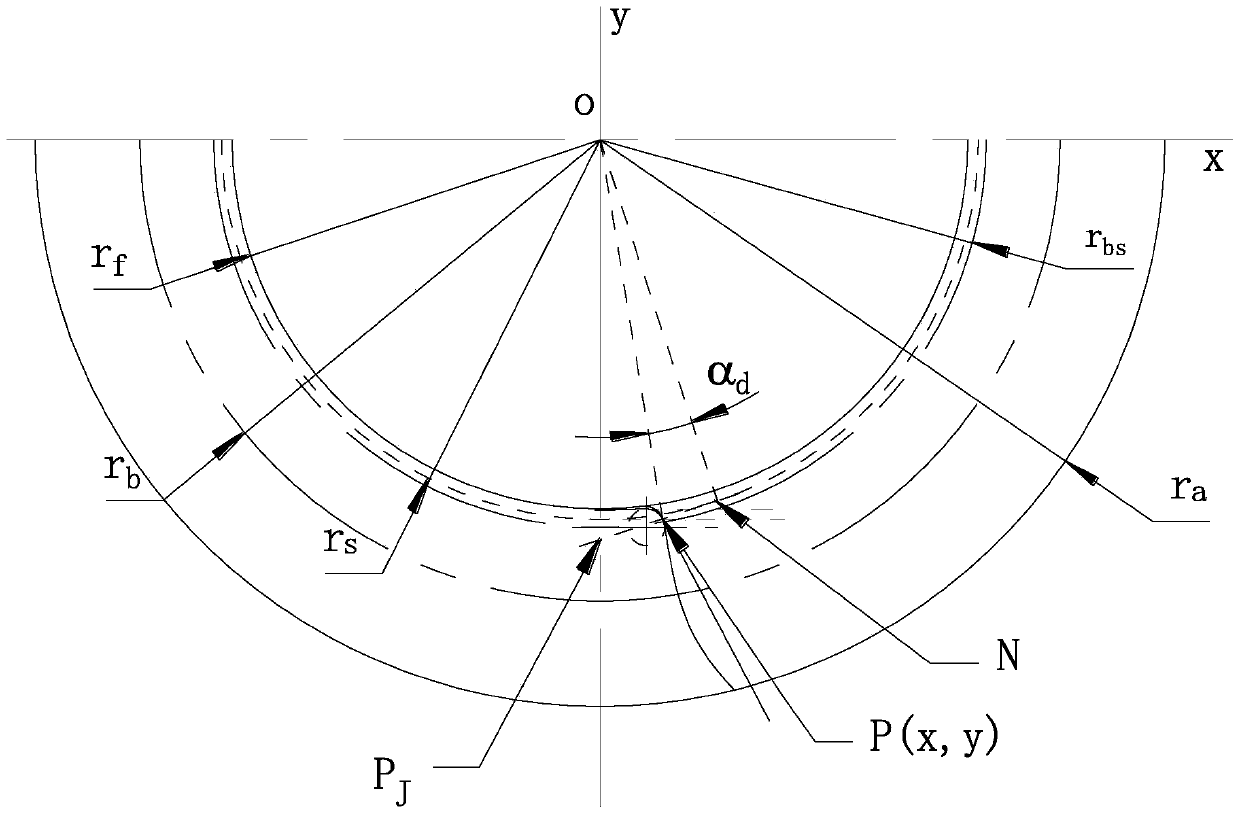

[0442] Embodiment 2: double large negative gear meshing transmission (i=1)

[0443] Steyr drive axle cylindrical gear, center distance a=193, transmission ratio i=1, calculate and determine pinion z 1 = 31, large gear z 2 =31, modulus m n =6.5, pressure angle α n =22.5°, helix angle β=14.92833333° (14°55'42"). Specific gear and hob parameters are shown in Table 3 and Table 4:

[0444] Table 3: Gear parameter table (double large negative gear transmission i=1)

[0445]

[0446]

[0447] Table 4: Hob parameter table

[0448] serial number

Embodiment 3

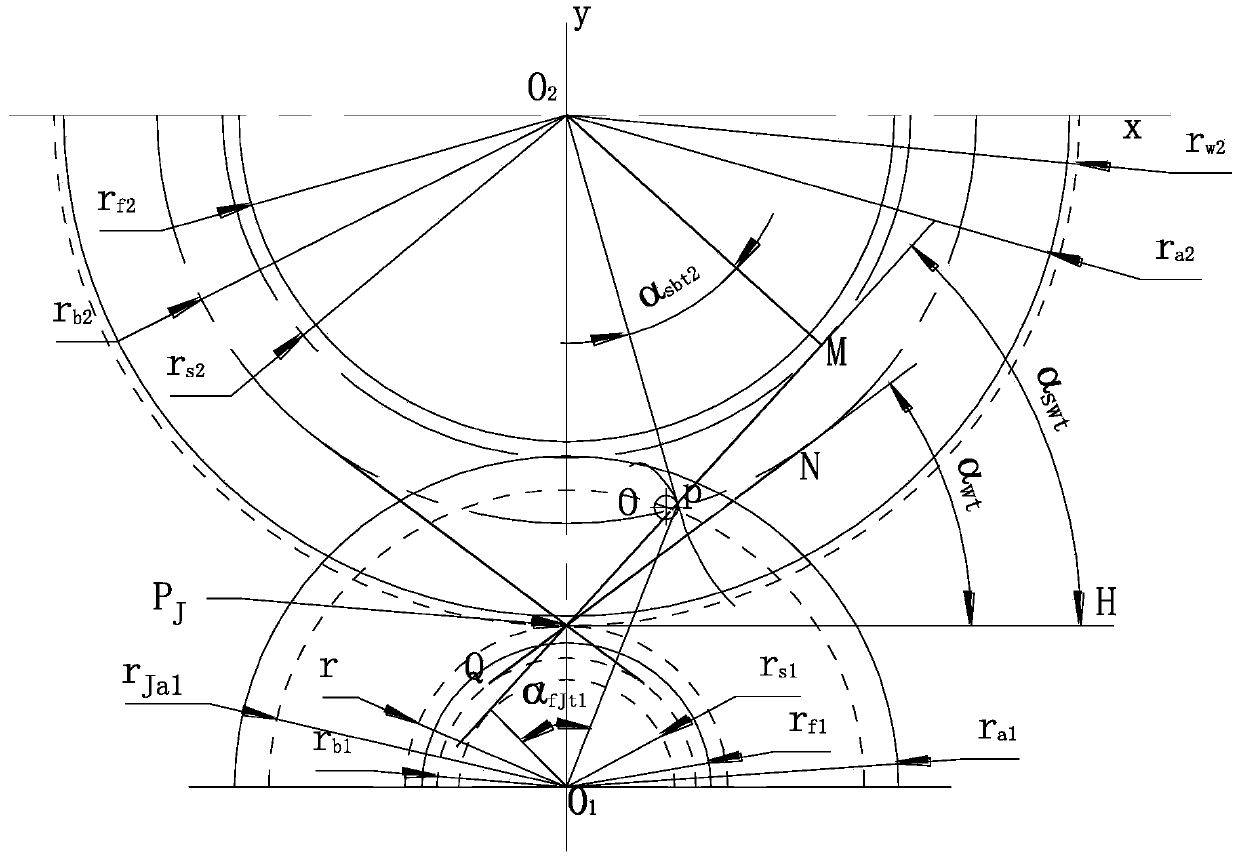

[0449] Embodiment 3: double large negative gear meshing transmission (i>1)

[0450] Steyr drive axle cylindrical gear, center distance a=193, transmission ratio i=1.2, pinion z is used for calculation 1 =28, large gear z 2 =34, modulus m n =6.5, pressure angle α n =22.5°, helix angle β=14.92833333° (14°55′42″), tooth width b=36. Specific gear and hob parameters are shown in Table 5 to Table 7:

[0451] Table 5: Gear parameter table (double large negative gear transmission i>1)

[0452]

[0453]

[0454] Table 6: Hob parameter table (pinion)

[0455] serial number

parameter name

the symbol

value

Remark

1

modulus

m n

6.5

2

Pitch circle normal pressure angle

α n

22.5°

3

Effective tooth height

h

10.675

Excluding addendum chamfer height

4

Boundary scalloped thickness

S Jl

8.708

5

Boundary crest height

h Ja

3.048

Pitch thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com