Ball valve

A ball valve and external valve technology, applied in valve devices, multi-port valves, cocks including cut-off devices, etc., can solve the problems of inability to achieve synchronous operation, high production costs, and many consumables, avoiding economic losses, low cost, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

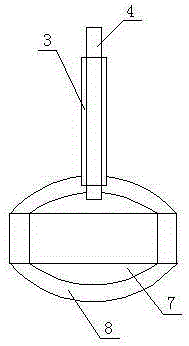

[0017] Such as figure 1 Shown: a composite valve ball, including an outer valve ball 8 arranged on the outer layer, an inner valve ball 7 is arranged inside the outer valve ball 8, and the inner valve ball 7 and the outer valve ball 8 are rotatably connected along the axis of the valve stem , the outer valve ball 8 is connected to the outer valve stem 3, the inner valve ball 7 is connected to the inner valve stem 4, and the valve ball is an ellipsoidal valve ball.

Embodiment 2

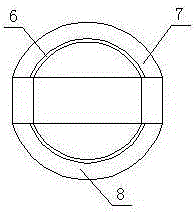

[0019] Such as figure 2 Shown: a composite valve ball, including an outer valve ball 8 arranged on the outer layer, an inner valve ball 7 is arranged inside the outer valve ball 8, the valve ball is a round valve ball, and the outer valve ball and the inner valve ball A rotary sealing component 6 is arranged between the balls.

Embodiment 3

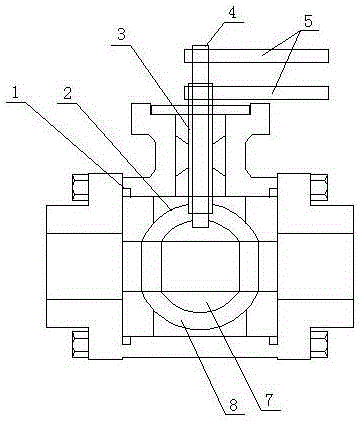

[0021] Such as image 3 Shown: a ball valve using the composite valve ball, including a ball valve body 1, a composite valve ball 2 and an operating mechanism 5, the composite valve ball 2 is arranged inside the ball valve body 1, and the exterior of the composite valve ball 2 The valve ball 8 is connected to the operating mechanism 5 through an outer ball connecting piece, and the inner valve ball 7 is connected to the operating mechanism 5 through an inner ball connecting piece. The outer ball connecting piece is a hollow outer valve stem 3 , and the inner ball connecting piece is an inner valve stem 4 arranged in the outer valve stem 3 . The operating mechanism 5 includes a composite valve ball synchronous control part and an asynchronous control part.

[0022] When the composite valve ball of the present invention and the ball valve using the composite valve ball are in use, on the one hand, by controlling the asynchronous control part on the operating mechanism, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com