High temperature damper valve shaft adiabatic transmission mechanism and assembly method thereof

A transmission mechanism and heat insulation technology, which is applied in the direction of valve devices, engine components, valve operation/release devices, etc., can solve problems such as actuator overheating, actuator damage, space structure restrictions, etc., to ensure accuracy and high efficiency , the effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

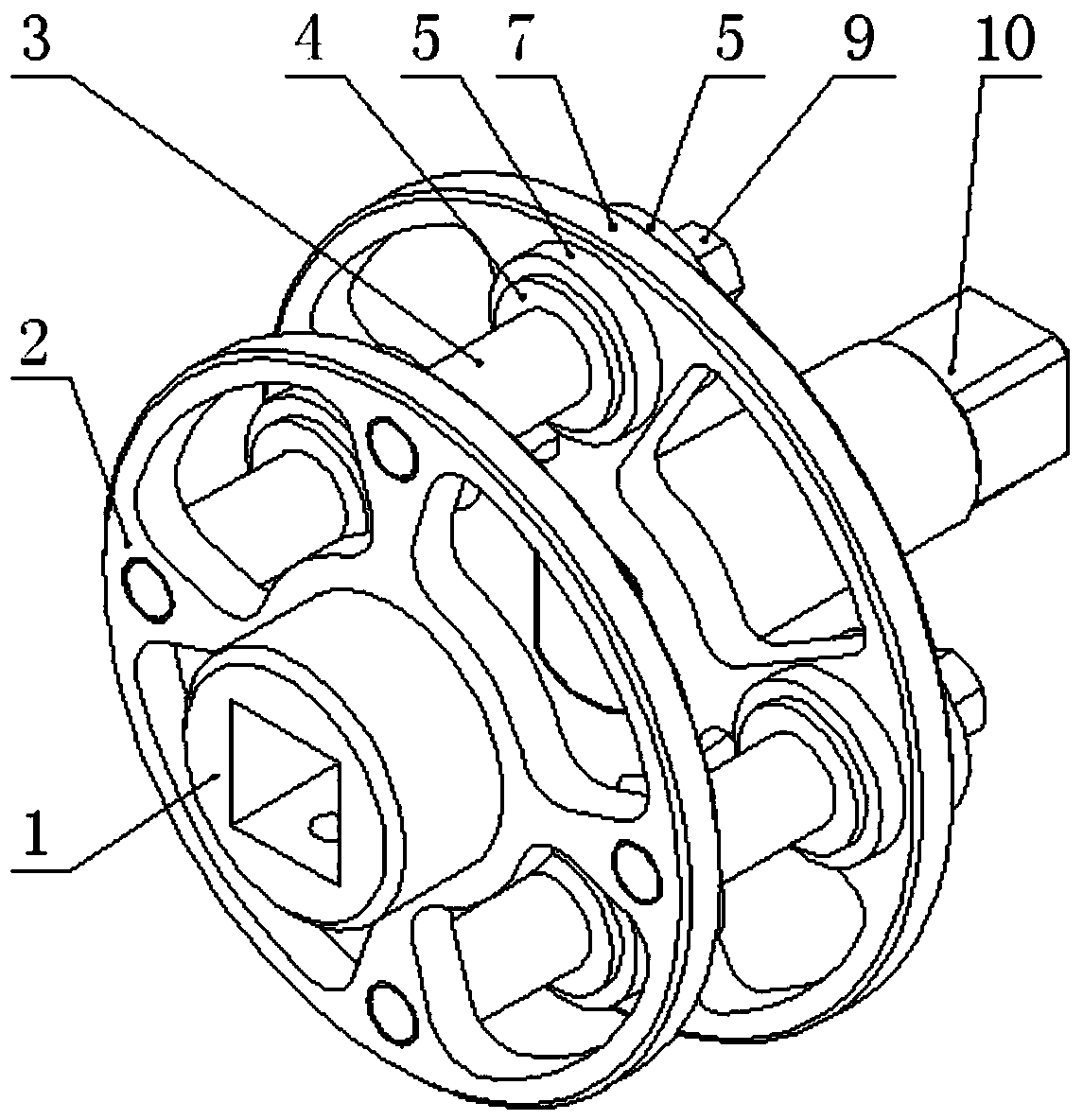

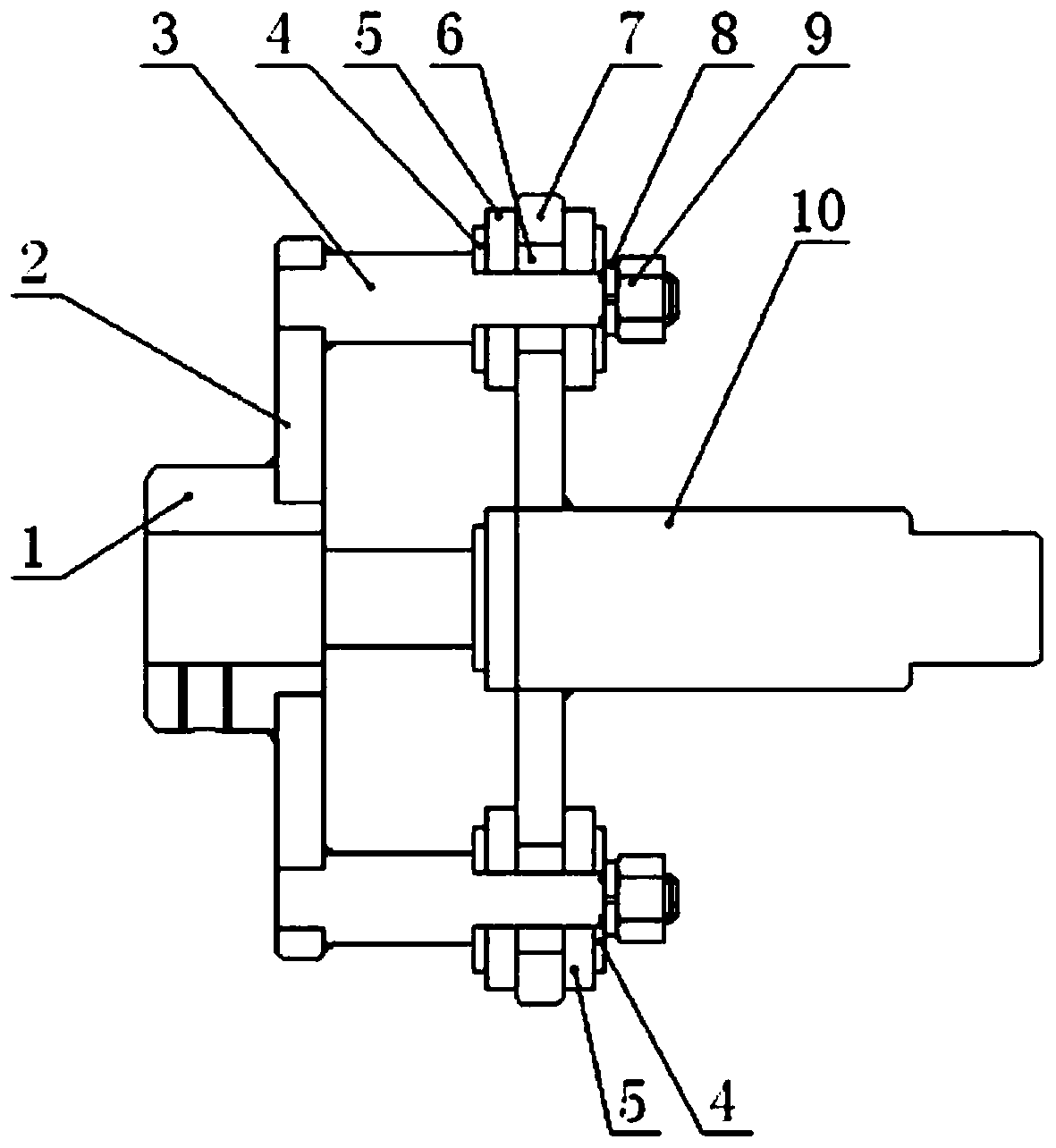

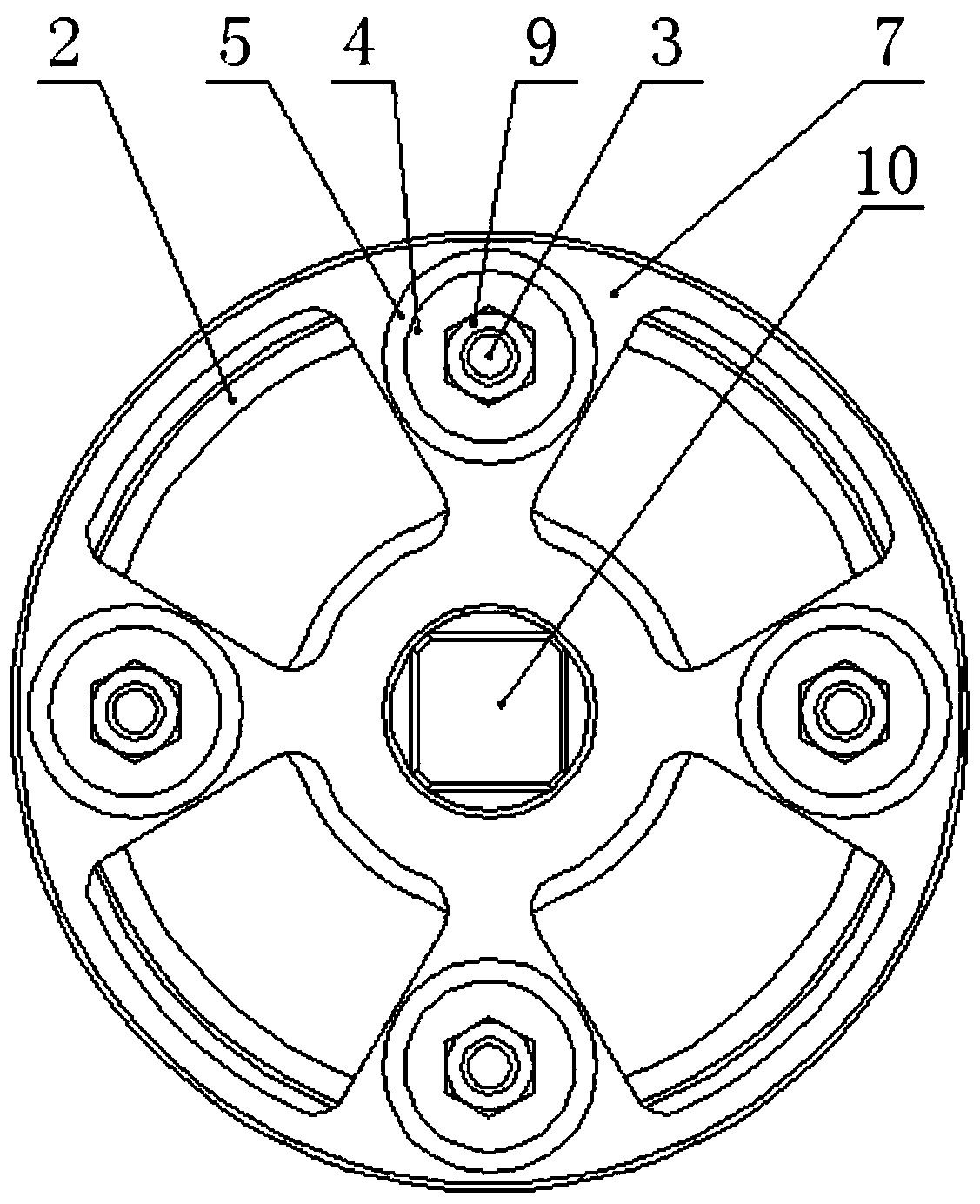

[0024] Attached below Figure 1-4 The present invention is described further:

[0025] The high-temperature damper valve shaft adiabatic transmission mechanism includes a main shaft connecting sleeve 1 connected with the damper valve shaft, the main shaft connecting sleeve 1 is fixedly connected to the main shaft turntable 2, and the main shaft turntable 2 is connected to the connecting shaft 3;

[0026] Both sides of the heat-insulating turntable 7 are fitted with heat-insulating mica pads 5, the gasket 4 is bonded to the heat-insulating mica pad 5, the heat-insulating turntable 7 is provided with a heat-insulating mica ring 6, and the connecting shaft 3 passes through the heat-insulating mica ring 6 in the heat-insulating turntable 7, and The heat-insulating mica pad 5 and the washer 4 attached to the outside of the heat-insulating turntable 7, the connecting shaft 3 is fastened and connected with the washer 4, the heat-insulation mica pad 5 and the heat-insulation turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com