Steel pipe contour online measurement method

A measuring method and technology of steel pipes, which are applied to measuring devices, instruments, and optical devices, etc., can solve problems such as errors and achieve the effect of eliminating errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Referring to the accompanying drawings, an embodiment of a steel pipe profile online measurement method according to the present invention is characterized in that it includes the following steps:

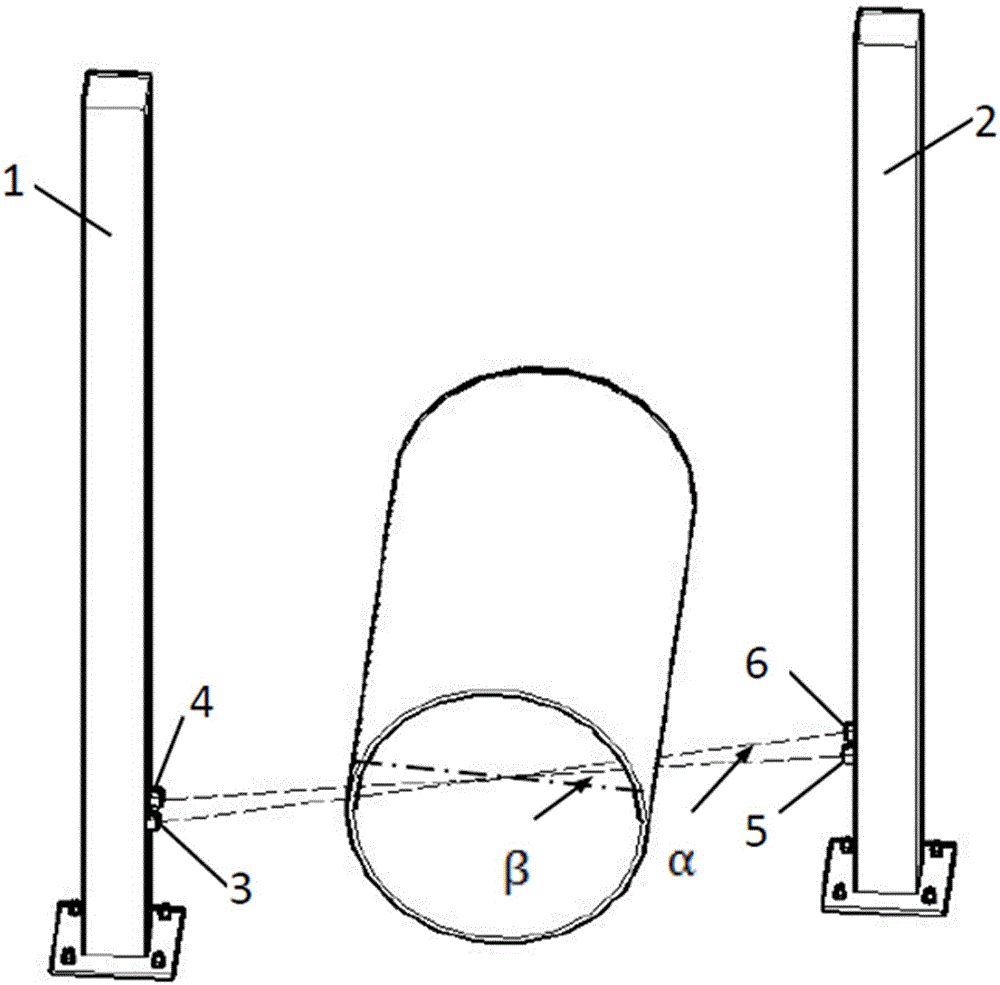

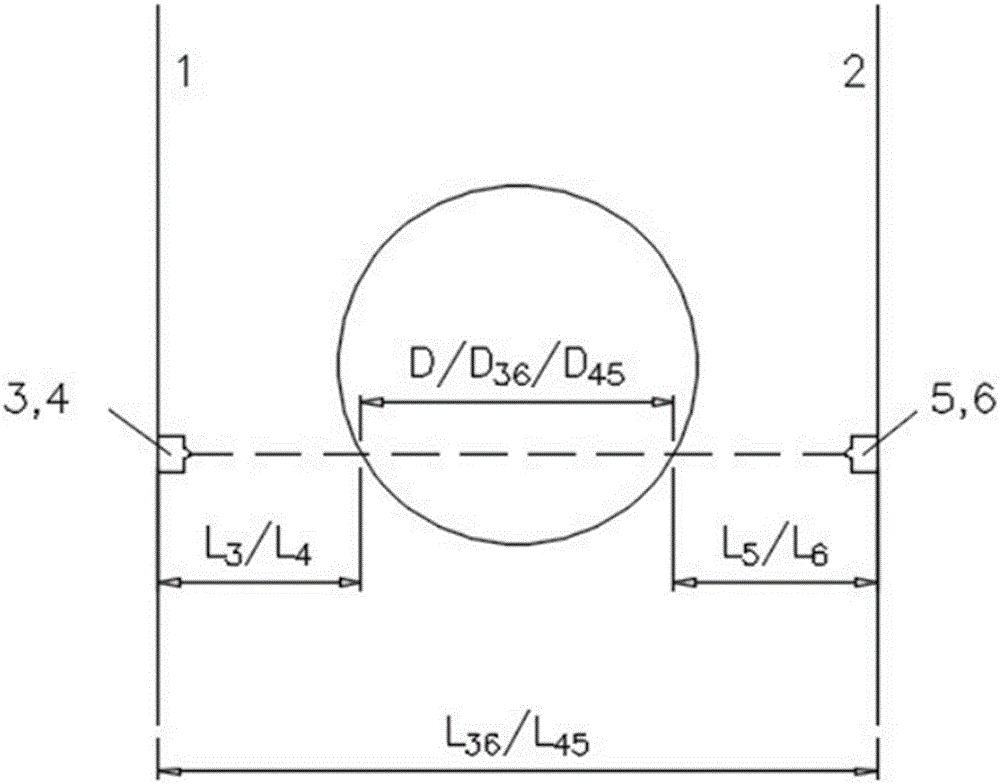

[0016] 1. Install two columns 1 and 2 on both sides of the end of the steel pipe at a position larger than the diameter of the steel pipe. Install the first laser displacement sensor 3 and the second laser displacement sensor 4 on the first column 1, and install the third laser displacement sensor on the second column 2. Laser displacement sensor 5 and the 4th laser displacement sensor 6, make four laser displacement sensors can move up and down synchronously, make the first laser displacement sensor 3 and the 4th laser displacement sensor 6 in the described laser displacement sensor be the first group, the second The laser displacement sensor 4 and the third laser displacement sensor 5 are the second group, and the two laser displacement sensors in each group are opposite ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com