Device for simultaneously detecting front and back surfaces of workpiece

A front and back, workpiece technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of not being able to detect the front and back of workpieces at the same time, restricting the automation of the PCB industry, and high production costs, so as to achieve flexible use and operation Change, reduce production cost, reduce the effect of multiple detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the present invention. But those skilled in the art should know that the following examples are not the sole limitation to the technical solution of the present invention, and any equivalent transformation or modification made under the spirit of the technical solution of the present invention should be considered as belonging to the protection of the present invention scope.

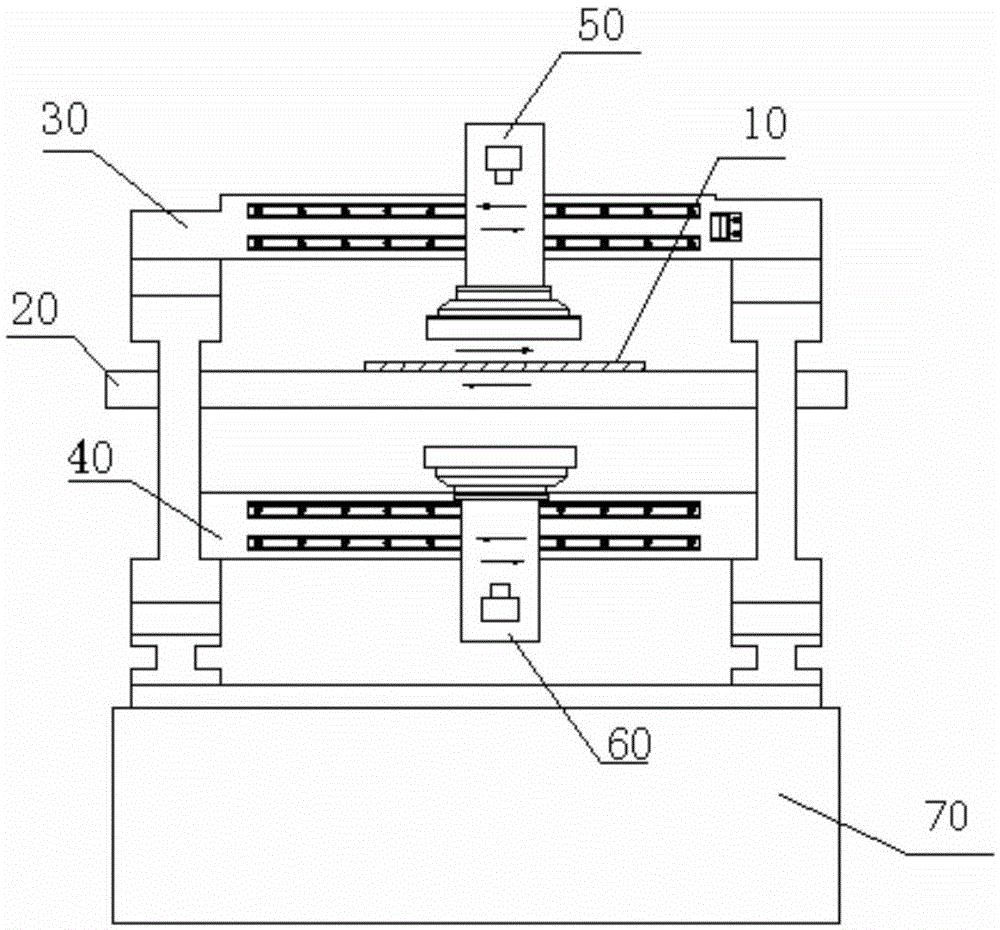

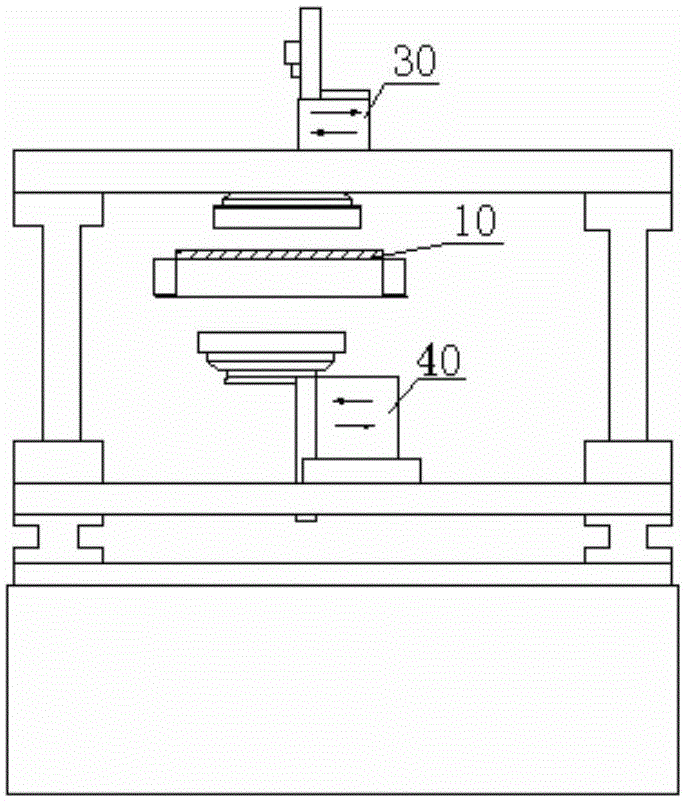

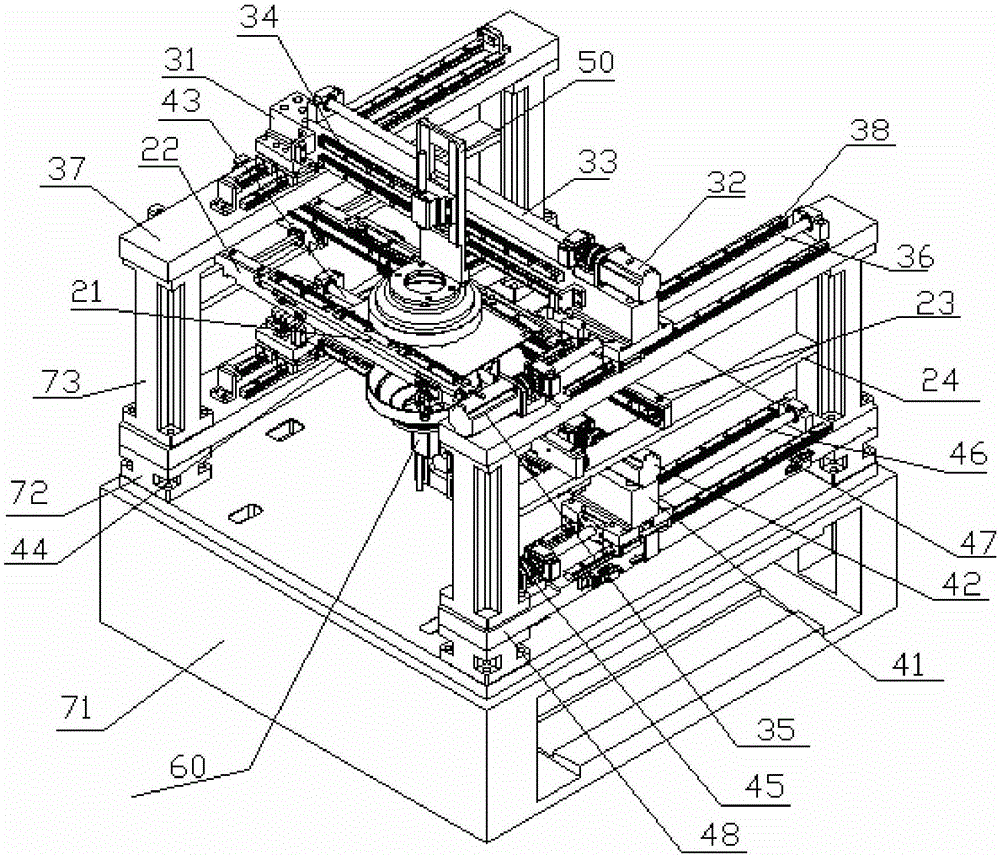

[0030] Refer to attached figure 1 and figure 2 , the working principle of simultaneous front and back detection by this device is: the workpiece 10 is transported to the position to be detected through the track conveying mechanism 20 as shown in the figure, the upper X, Y movement mechanism 30, and the lower X, Y movement mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com