Battery internal resistance detection circuit and battery internal resistance detection method and apparatus

A technology for detecting circuits and battery packs, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems such as complexity and circuit structure, and achieve the effect of simplifying the design structure and reducing design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0059] The invention provides a battery pack internal resistance detection circuit and a battery pack internal resistance detection method and device.

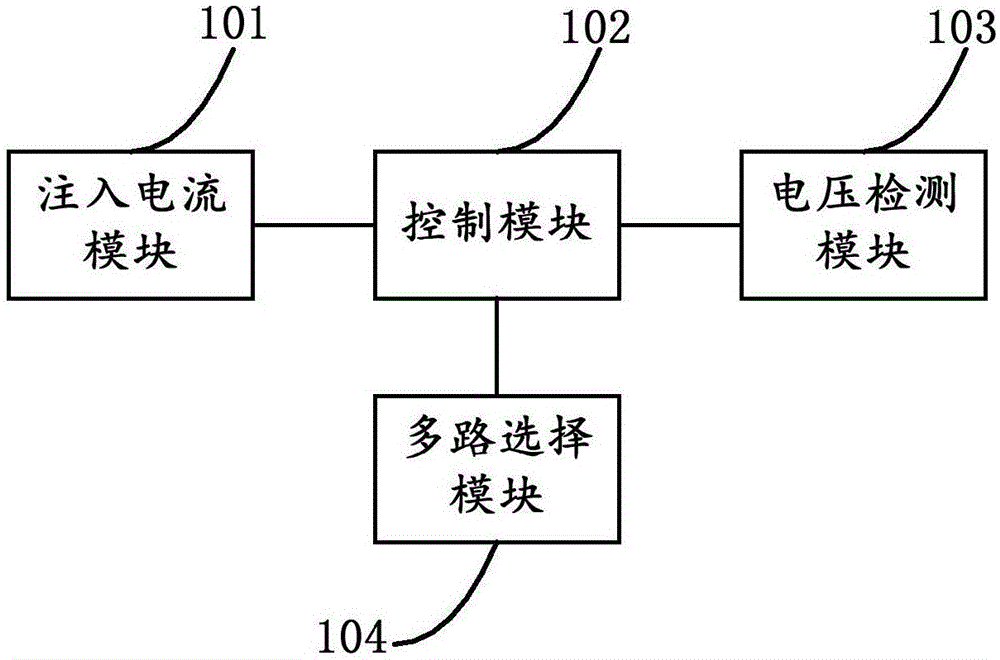

[0060] figure 1 It is a schematic structural diagram of a battery pack internal resistance detection circuit provided by the present invention; the circuit specifically includes: an injection current module 101, a control module 102, a voltage detection module 103 and a multi-channel selection module 104;

[0061] The injection current module 101 is configured to input current into the battery pack to be detected according to the current injection signal sent by the control module 102;

[0062] The control module 102 is used to control the injection current module 101, the voltage det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com