Method for obtaining parameter of overhead line subjected to creep elongation

A kind of plastic creep elongation, overhead line technology, applied in data processing applications, electrical digital data processing, special data processing applications, etc., can solve the problem of rough range of plastic elongation, inability to simulate power lines, and difficult to predict the plastic creep characteristics of power lines. , to achieve a highly reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

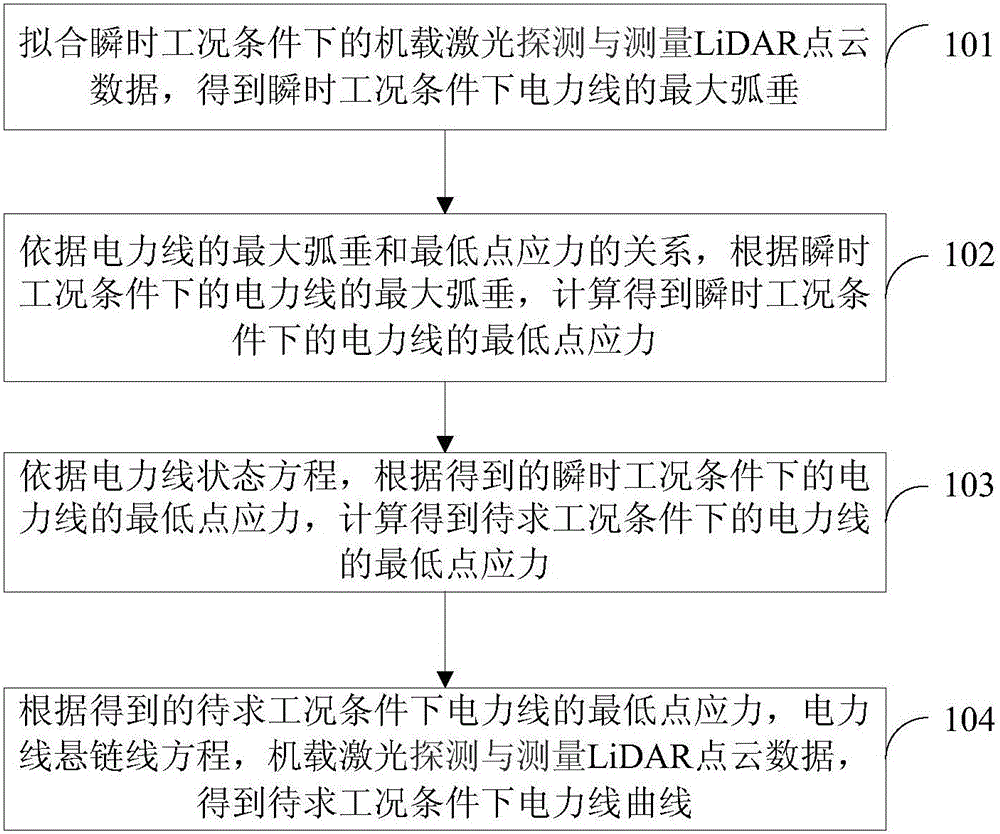

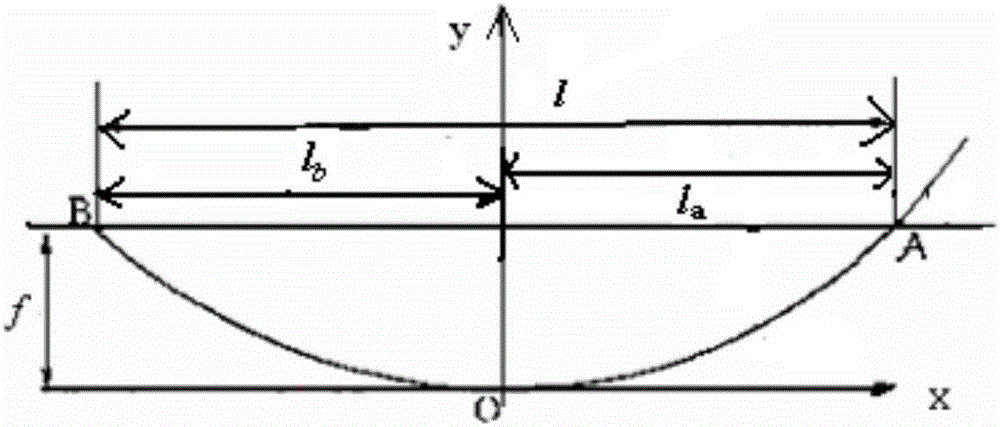

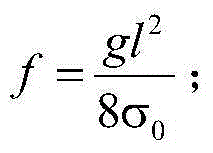

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0044] Existing methods for predicting parameters after plastic creep elongation of overhead lines generally use test methods. Due to the influence of measuring equipment and operator proficiency in this test method, the test results may not be credible; The test data and engineering experience give a rough range for the parameters after plastic creep elongation, which makes the measurement of the parameters after plastic creep elongation of overhead lines lack of measurement standards; this test method obtains the creep curve by simulating the power line in the natural environment, and then Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com