A kind of composite semi-hard magnetic material and preparation method thereof

A semi-hard magnetic and strip technology, applied in the direction of magnetic materials, metal material coating technology, magnetic objects, etc., can solve the problems of double-layer patch, interference with normal processes, easy adhesion, etc., to improve weather resistance stability, improve The effect of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

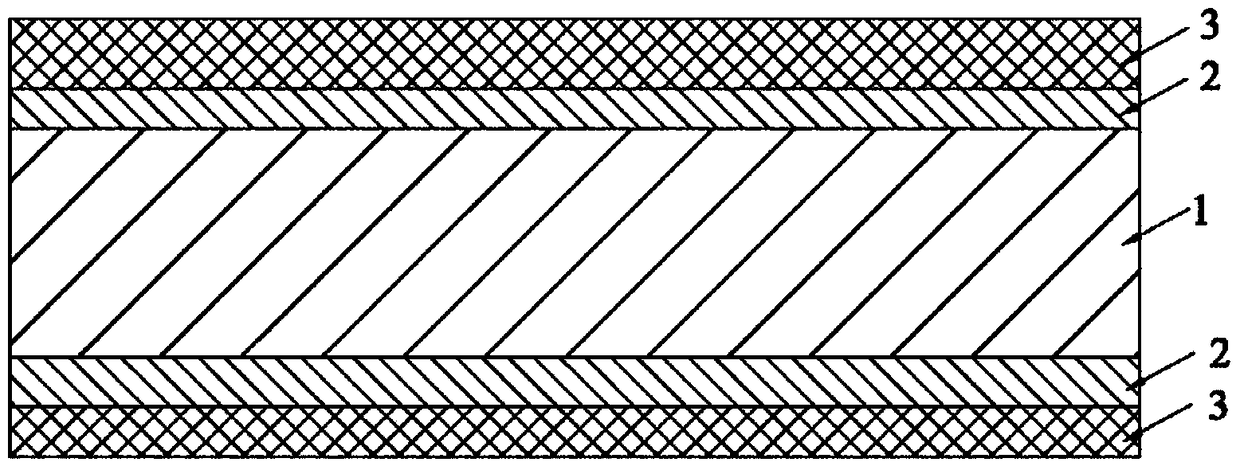

[0030] like figure 1 As shown, a composite semi-hard magnetic material according to an embodiment of the present invention includes a base layer 1 made of a semi-hard magnetic material. The outer surface of the base layer 1 is coated with an anti-oxidation layer 2 and an insulating layer 3. Between the base layer 1 and the insulating layer 3. Coating the anti-oxidation layer 2 on the surface of the semi-hard magnetic material greatly improves the anti-oxidation ability of the material itself, ensuring that the final acoustomagnetic sensor can maintain the stability of the semi-hard magnetic state in the most severe environment; The semi-hard magnetic material with the anti-oxidation layer 2 is insulated to effectively reduce the magnetic attraction between the semi-hard magnet and the semi-hard magnet and when the semi-hard magnet is adjacent to the amorphous resonant sheet.

[0031] Preferably, the semi-hard magnetic material is Fe-Ni-Al alloy, that is, the semi-hard magneti...

Embodiment 2

[0043] A kind of composite semi-hard magnetic material of this embodiment, its difference with the composite semi-hard magnetic material described in embodiment 1 is: described semi-hard magnetic material is Fe-Ni-Al-Ti alloy, namely semi-hard magnetic material is made of Fe a Ni b al c Ti dComposition of alloy composition, in which, a, b, c are atomic percentages, a=78, b=20, c=1, d=1; the phosphating layer is composed of zinc-based phosphating solution, and its pH value is 2.5; organic The coating consists of a polyurethane topcoat; the anti-oxidation layer 2 has a thickness of 5 μm, and the insulating layer 3 has a thickness of 5 μm.

[0044] The preparation method of the composite semi-hard magnetic material described in this embodiment is:

[0045] (1) Master alloy smelting: smelting by vacuum smelting method, putting alloy components into a crucible, heating to a temperature of 1650°C, refining for 10 minutes after the alloy components are melted, and pouring into st...

Embodiment 3

[0052] A kind of composite semi-hard magnetic material of this embodiment, its difference with the composite semi-hard magnetic material described in embodiment 1 is: described semi-hard magnetic material is Fe-Ni-Al-Ti alloy, namely semi-hard magnetic material is made of Fe a Ni b al c Ti d Composition of alloy composition, where a, b, c are atomic percentages, a=83, b=15, c=1.5, d=0.5; the phosphating layer is composed of manganese-based phosphating solution, and its pH value is 3; organic The coating is made of phenolic resin; the thickness of the anti-oxidation layer 2 is 10 μm, and the thickness of the insulating layer 3 is 15 μm.

[0053] The preparation method of the composite semi-hard magnetic material described in this embodiment is:

[0054] (1) Master alloy smelting: smelting by vacuum smelting method, putting alloy components into a crucible, heating to a temperature of 1550°C, refining for 15 minutes after the alloy components are melted, and pouring into ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com