Spring-type magnetic holding relay

A magnetic latching relay, spring-type technology, applied in the direction of electromagnetic relay, relay, electromagnetic relay details, etc., can solve the problem that the magnetic latching relay is difficult to maintain the contact state, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

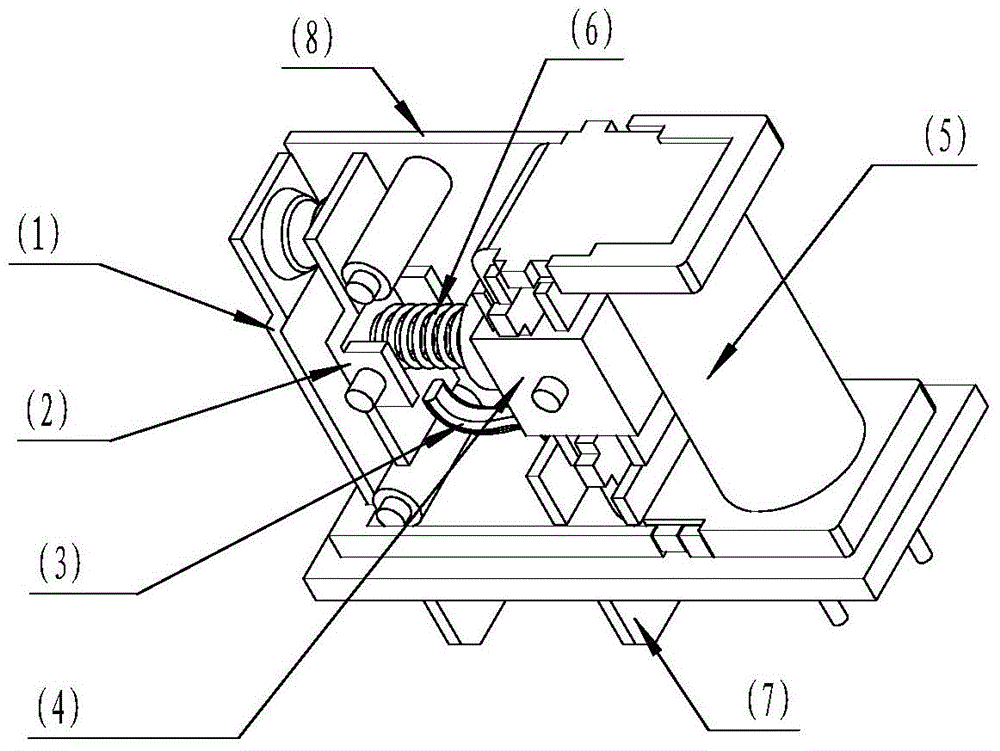

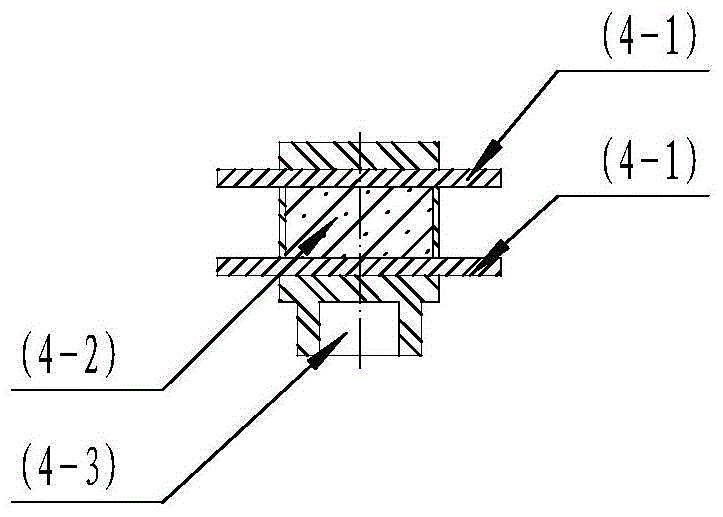

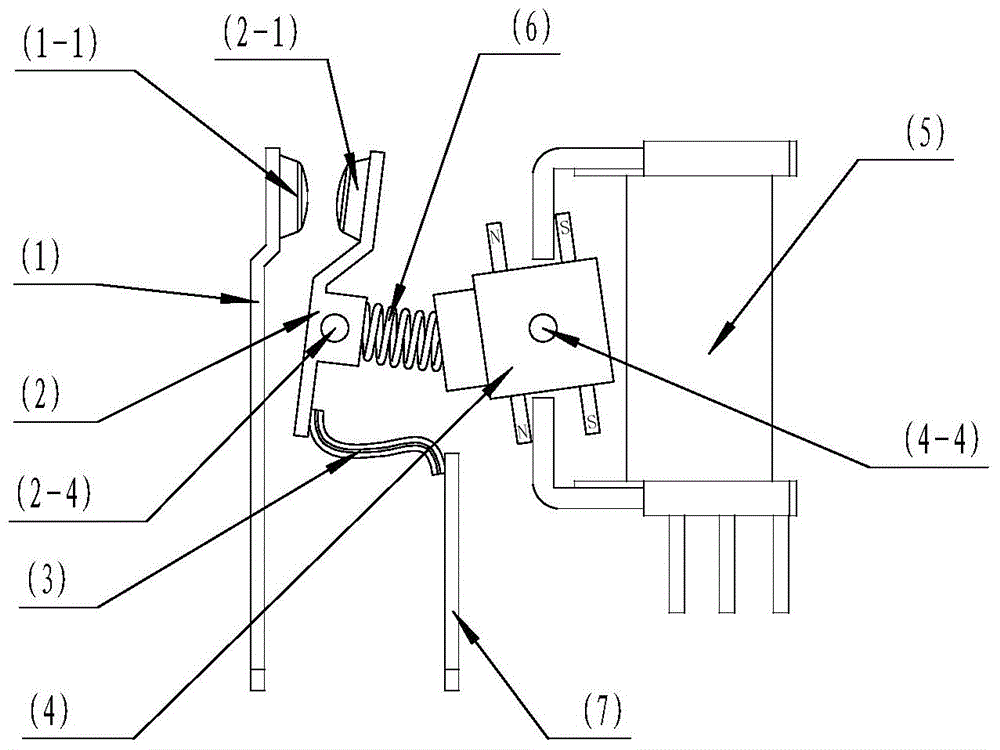

[0013] Specific embodiments: The spring type magnetic latching relay includes a coil assembly (5), an armature assembly (4), a support fixed plate (8), a static contact plate (1), a moving contact plate (2), and a spring (6) as the main components. Its characteristics: the coil assembly (5) adopts the disclosed patent method for forward and reverse winding, when the coil assembly (5) is supplied with a positive pulse voltage, the armature assembly (4) moves, and the armature assembly (4) rotates the axis with the armature ( 4-4) rotates as the center, and the deflection force generated by the spring (6) is transmitted to the moving touch panel (2), so that the moving touch panel (2) rotates around the moving axis (2-4) of the moving touch panel, driving the moving touch panel The plate (2) rotates, forcing the moving contact (2-1) to close with the static contact (1-1), as Figure 4 When the reverse pulse voltage is applied to the coil assembly (5), the armature assembly (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com