High power factor crm Buck PFC converter

A high power factor, converter technology, applied in the direction of output power conversion device, high-efficiency power electronic conversion, climate sustainability, etc., can solve the problem that the power factor value cannot reach 1, and achieve the effect of improving the power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

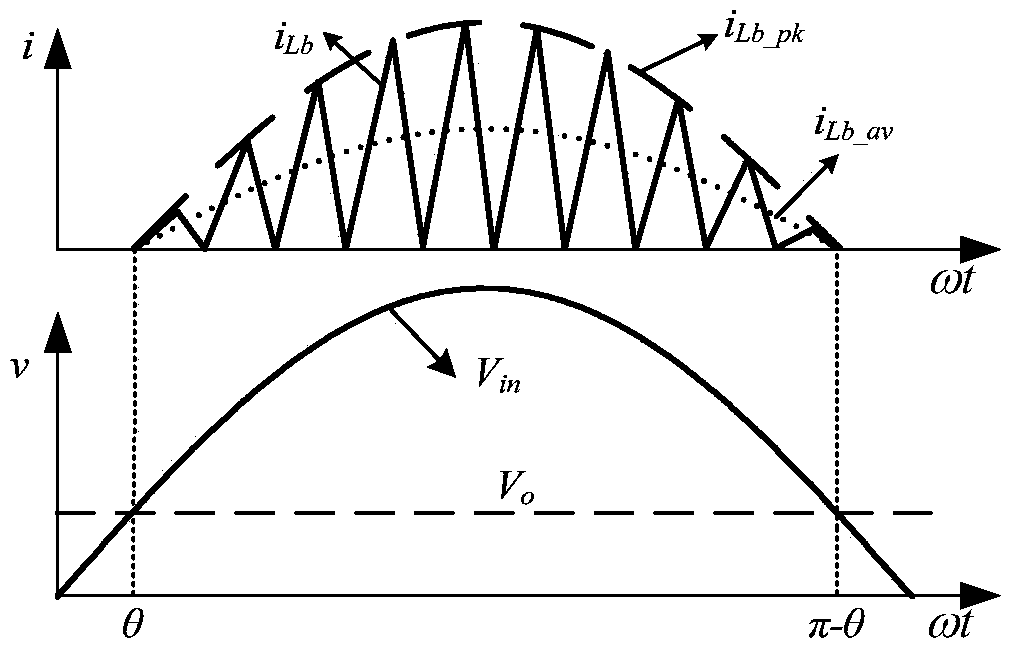

[0025] 1 Working principle of CRM Buck PFC converter

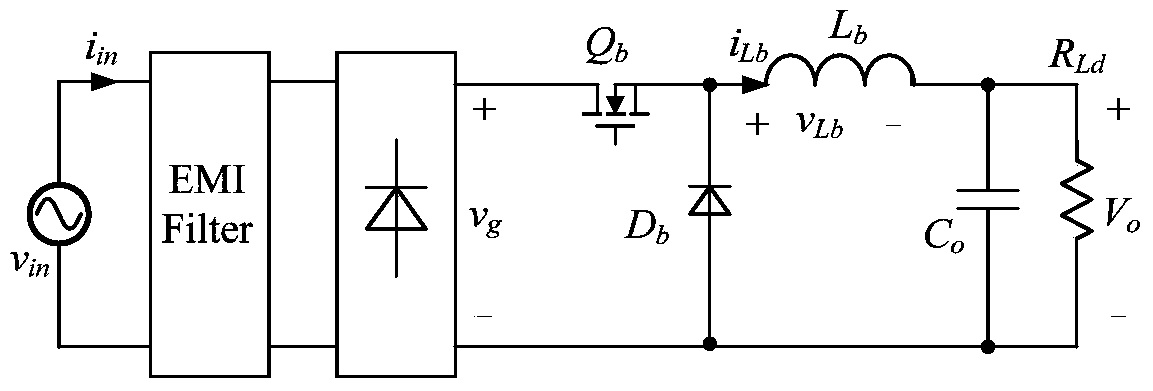

[0026] figure 1 It is the main circuit of the Buck PFC converter.

[0027] For the convenience of analysis, the following assumptions are first made: 1. All devices are ideal components; 2. The output voltage ripple is very small compared with its DC value; 3. The switching frequency is much higher than the input voltage frequency.

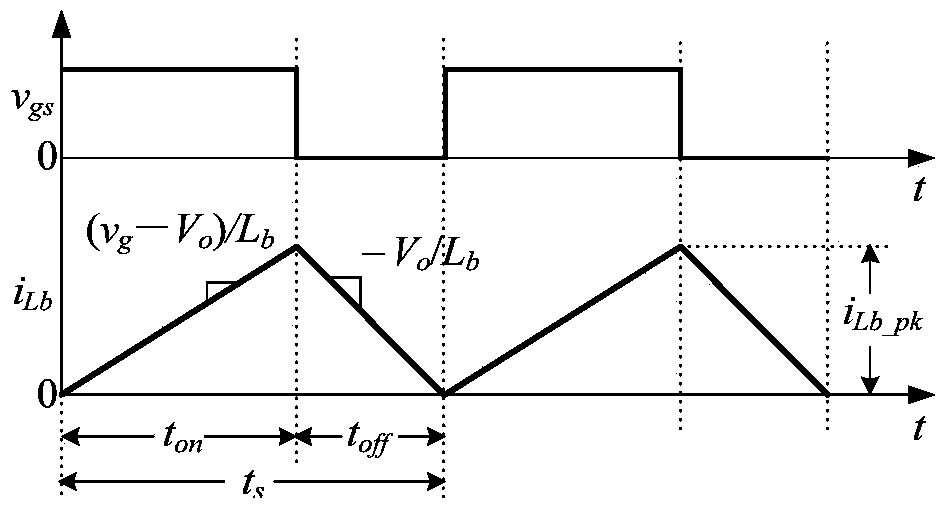

[0028] figure 2 The inductor current waveform in one switching cycle when CRM is given. When Q b When turned on, D b cutoff, the boost inductor L b The voltage across it is v g -V o , its current i Lb Start with zero and start with (v g -V o ) / L b The slope increases linearly. When Q b When shutting down, i Lb by D b freewheeling, at this time L b The voltage across it is v o , i Lb with V o / L b the slope of the drop. Since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com