Evaporative cooling system with liquid-to-air membrane energy exchanger

An air heat exchanger, evaporative cooling technology, applied in natural cooling systems, energy recovery systems for ventilation and heating, air conditioning systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

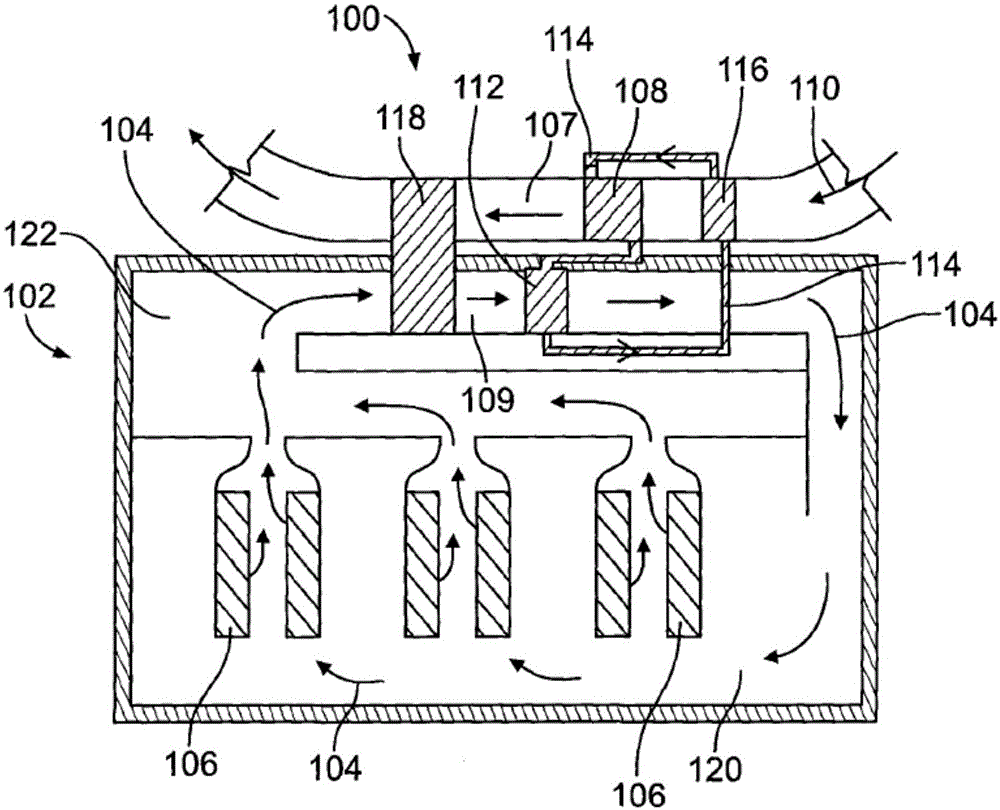

[0031] The evaporative cooling system 100 described here can cool the process airflow 104 to a wet bulb temperature lower than that of the outdoor air (for example, the cleaning air 110) without requiring dehumidification or supplemental cooling (for example, a cooler) of the outdoor air. temperature. The process airflow 104 may be cooled to a temperature theoretically close to the dew point of outdoor air. Although dehumidification and / or supplemental cooling are not required, the additional operations and / or components can be added to the system 100 to facilitate cooling of the process gas flow 104, as in one or more embodiments described herein.

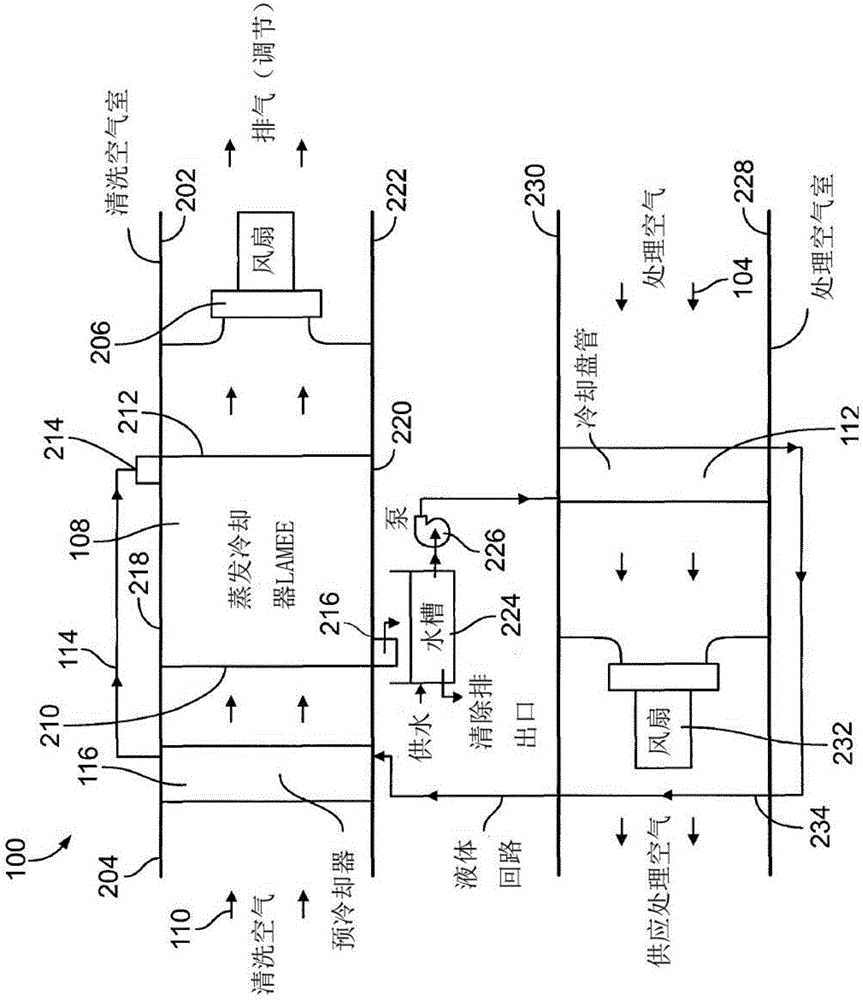

[0032] figure 2 Yes figure 1 A schematic diagram of an embodiment of the evaporative cooling system 100 shown. figure 2 The illustrated evaporative cooling system 100 includes components that allow the evaporative cooling fluid 114 to cool the process airflow 104 and pre-cool the cleaning airflow 110. In the illustrated embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com