Integrated evaporative cooler and flat plate air to air heat exchanger

a technology of air to air heat exchanger and evaporative cooler, which is applied in the direction of lighting and heating apparatus, heating types, laminated elements, etc., can solve the problems of low operational cost, reduced peak demand relative to standard direct refrigeration system, and no details concerning configuration and critical design features of components, so as to reduce the energy required to maintain the building environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

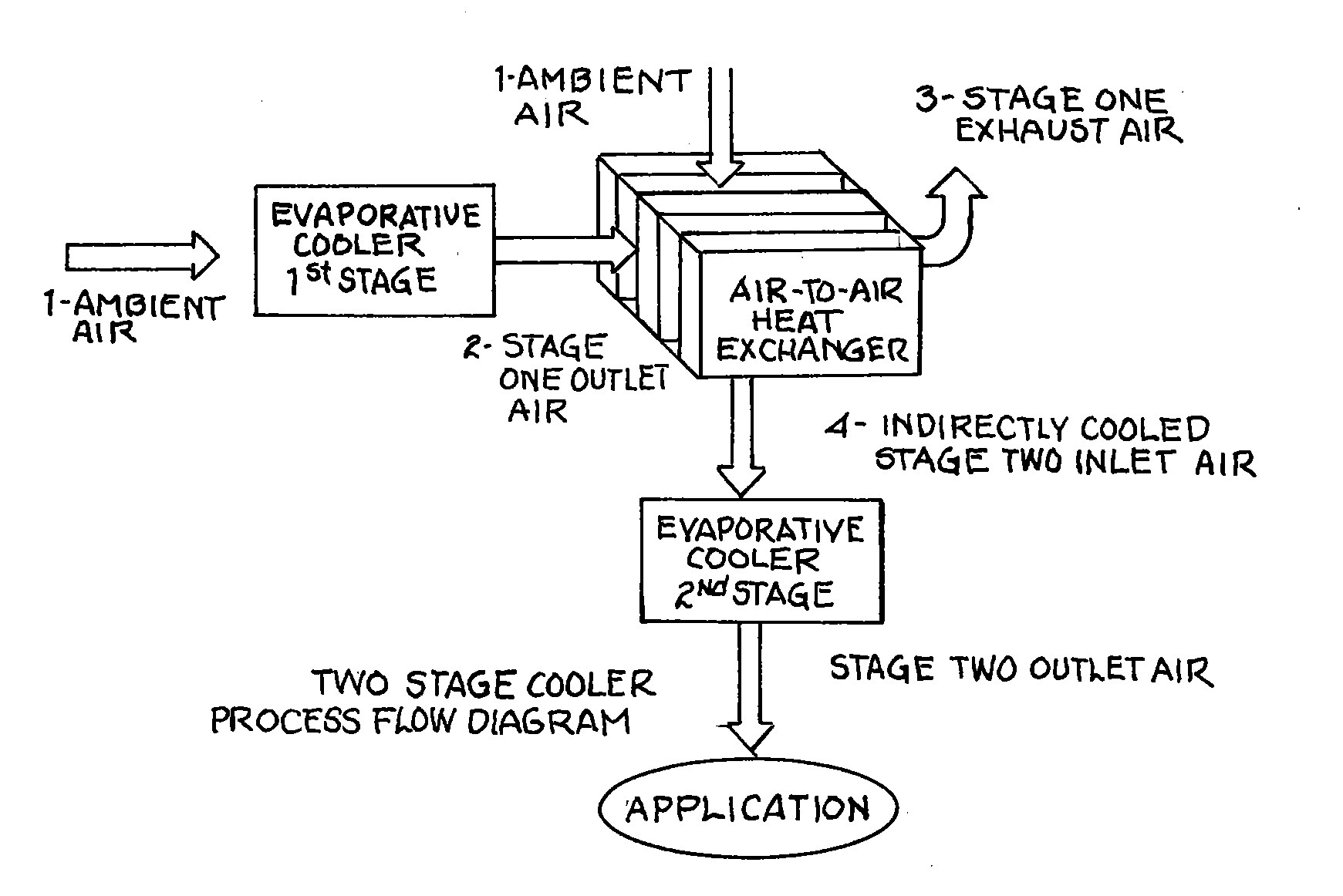

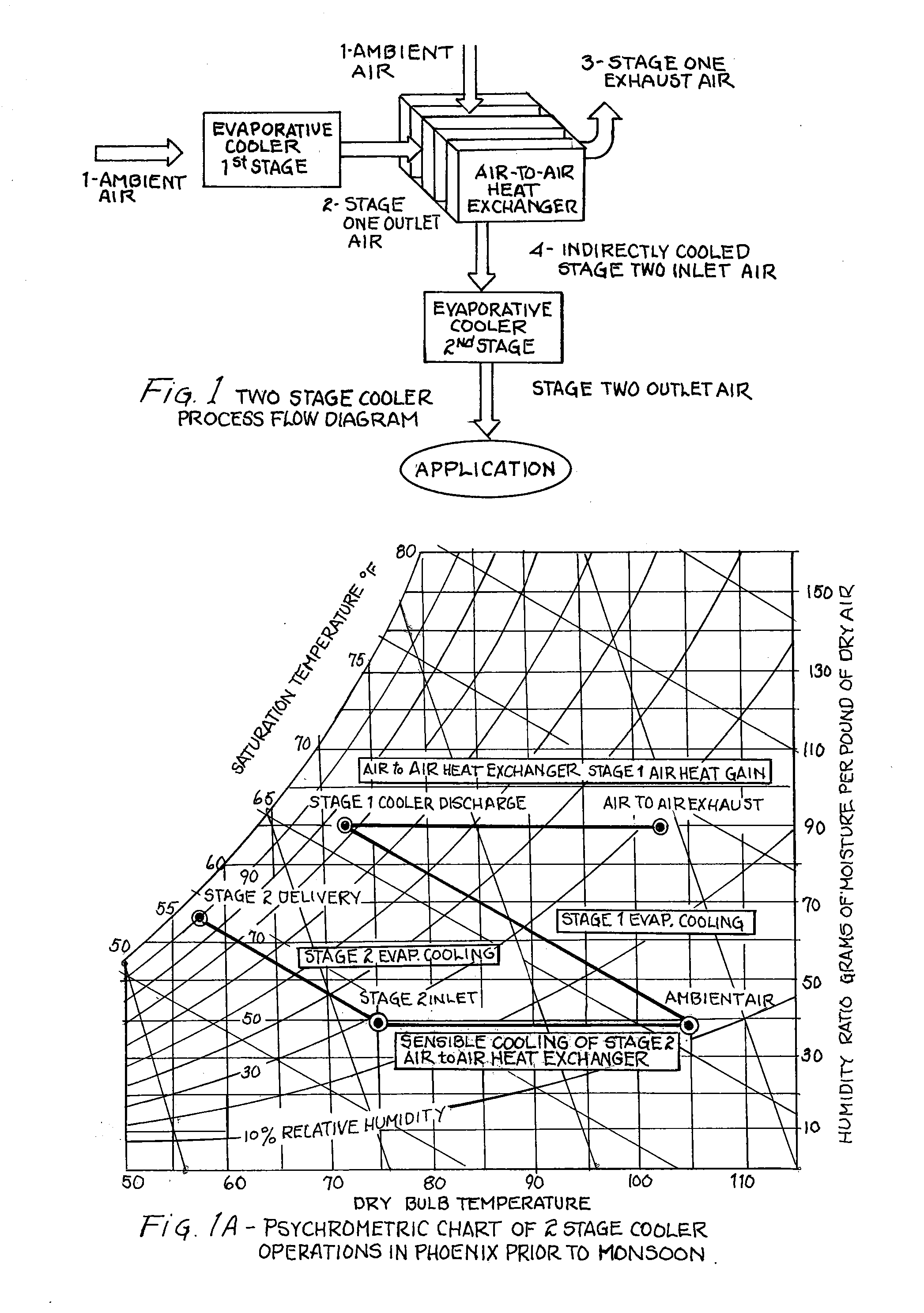

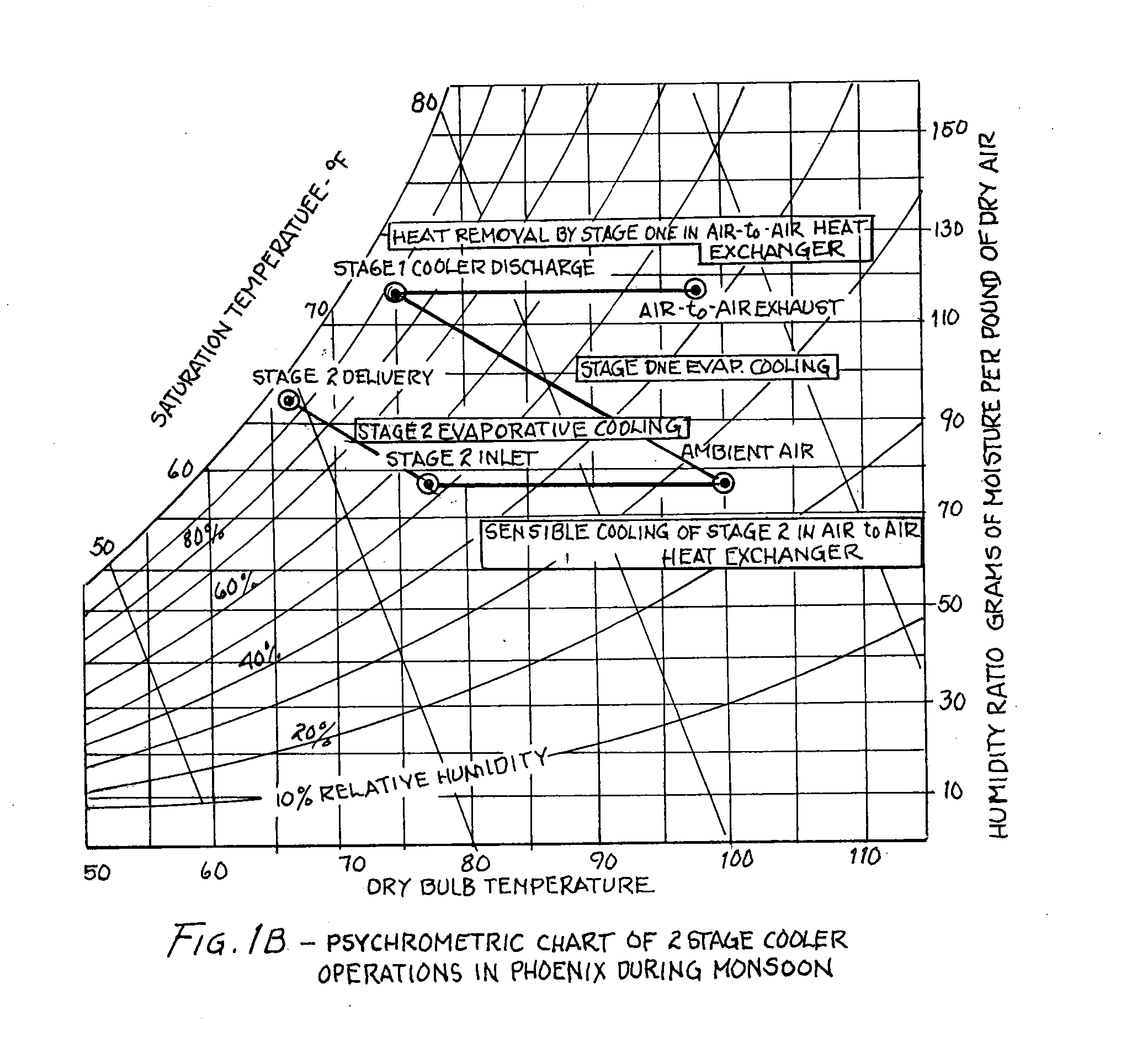

[0072]This invention is an integrated system comprised of a flat plate, air-to-air heat exchanger, ducting and controls, and an AZFlow™ direct evaporative cooler in configurations where the system is able to provide air that has been cooled well below the ambient wet-bulb to temperatures approaching the dew point. Three configurations with two alternate air-to-air heat exchangers are discussed in this section. These are: a) Two stage evaporative cooling, b) Building energy recovery cooling, and c) Indirect evaporative cooling.

[0073]Anyone skilled in the art of cooling system design will both understand the significance and uniqueness of the invention and the broad range of applications and design options that can be deployed to implement the key features and derive the associated benefits. In this regard, the descriptive material presented below is not meant in any way to bound or otherwise limit the embodiment to an approach or set of parameters but is presented only as a way of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com