Closed evaporation cooling high-temperature cold water unit

An evaporative cooling and chiller technology, which is applied in the fields of evaporative cooling high temperature chillers and closed evaporative cooling high temperature chillers, can solve the problems of inability to meet the water temperature requirements of the sensible heat terminal, unsuitable for use in the northwest region, and easily polluted circulating water. Achieve the effects of avoiding condensation at the sensible heat end, less susceptible to pollution, good energy saving and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

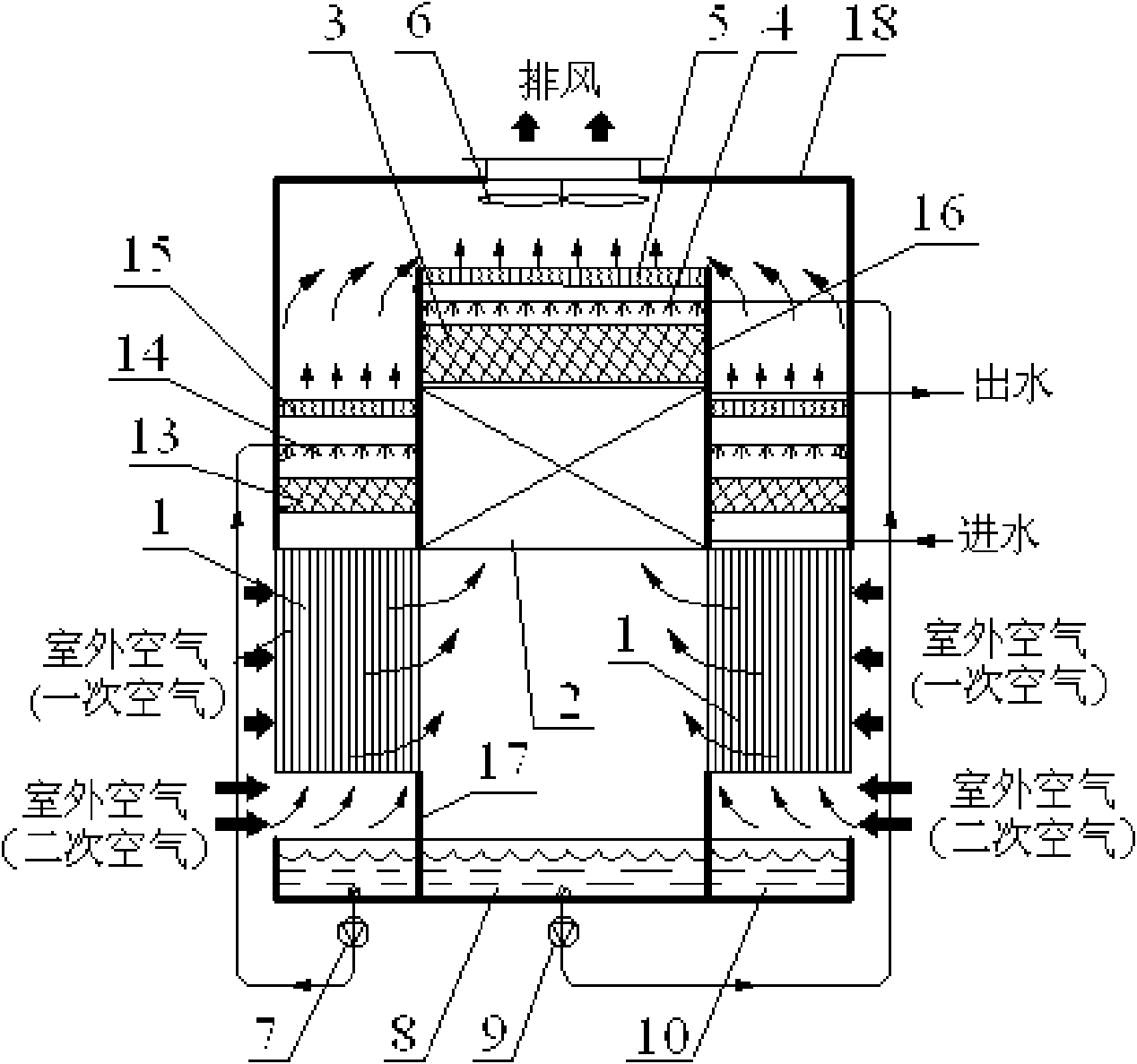

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

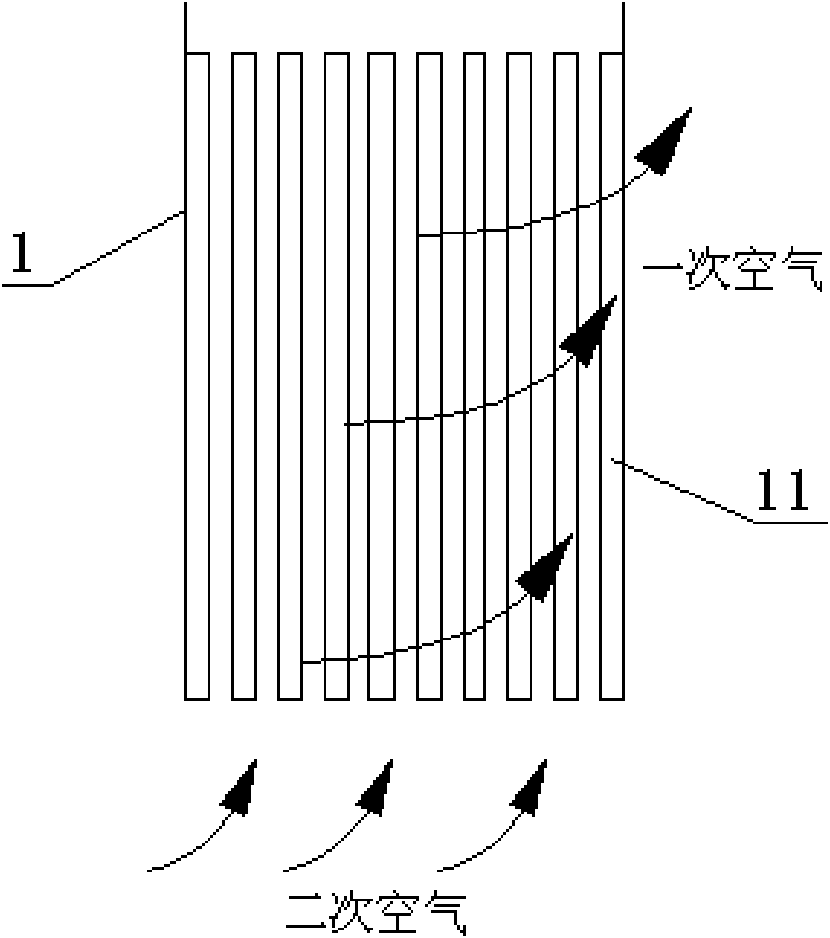

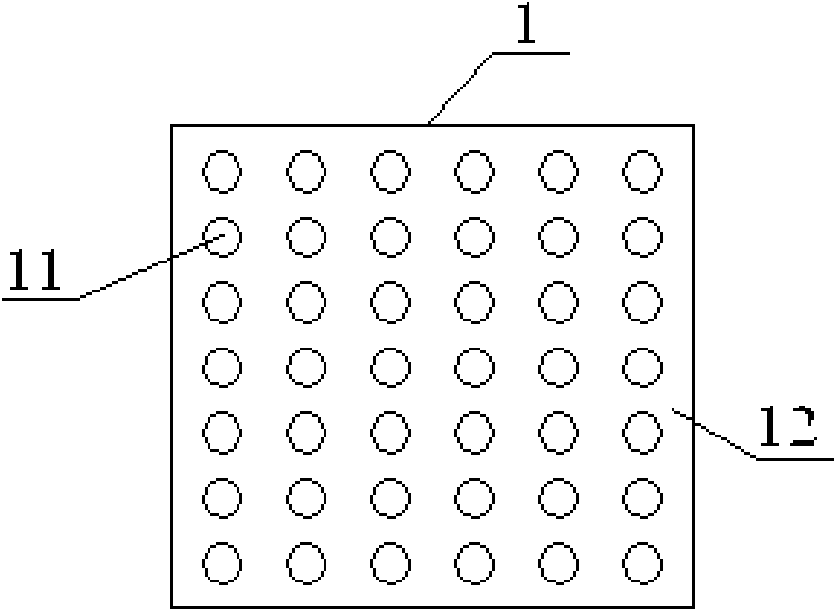

[0020] The structure of the water chiller of the present invention, such as figure 1 As shown, the evaporative cooling coil 2 is included, and the water inlet and outlet of the evaporative cooling coil 2 are respectively connected with the circulating water device of the air conditioning system. The evaporative cooling coil 2 is surrounded by a partition 16 . The upper part of the evaporative cooling coil 2 is provided with filler I 3 , water distributor I 4 and water baffle I 5 sequentially from bottom to top, and the filler I 3 , water distributor I 4 and water baffle I 5 are located on the partition 16 Inside, on both sides of the bottom of the evaporative cooling coil 2, a set of tubular indirect evaporative coolers 1 are arranged respectively, and the upper part of each set of tubular indirect evaporative coolers 1 is provided with fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com