High temperature and high pressure sterilization process for purplish black waxy corn

A technology of high temperature and high pressure sterilization and purple black waxy corn, which is applied in the field of food processing, can solve the problems of packaging bag expansion, company economic loss, deterioration, etc., and achieve the effect of improving quality, enhancing competitiveness, and maximizing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of purple waxy corn blanching and cooling process comprises the following steps:

[0028] The high-temperature and high-pressure sterilization process of purple black waxy corn includes a high-pressure boiler A and a high-pressure boiler B, which are connected by connecting pipes, and there are circulation valves on the connecting pipes; the operation steps are as follows:

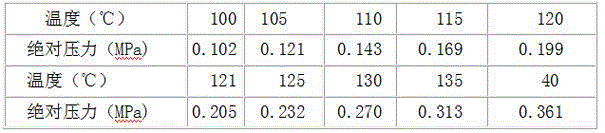

[0029] The first step: close the hatch of the high-pressure boiler A, pressurize the pot to 2 kg, add 1.3 cubic meters of cold water, and heat the water temperature to 115°C with steam; the second step: use high-temperature-resistant, non-toxic special plastic The vacuum-packed corn is put into a stainless steel cart, which is full of transparent holes, so that water can flow from all angles, and the cart is pushed into the high-pressure boiler B. After the hatch is closed, the pressure in the boiler is increased to 2 kg, open the circulation valve of the connecting pipe between...

Embodiment 2

[0030] Embodiment 2: a kind of purple waxy corn blanching and cooling process comprises the following steps:

[0031] The high-temperature and high-pressure sterilization process of purple black waxy corn includes a high-pressure boiler A and a high-pressure boiler B, which are connected by connecting pipes, and there are circulation valves on the connecting pipes; the operation steps are as follows:

[0032] Step 1: Close the hatch of the high-pressure boiler A, pressurize the pot to 2.5 kg, add 1.7 cubic meters of cold water, and heat the water to 125°C with steam; Step 2: Use high-temperature-resistant, non-toxic special plastic The vacuum-packed corn is put into a stainless steel cart, which is full of transparent holes, so that water can flow from all angles, and the cart is pushed into the high-pressure boiler B. After the hatch is closed, the pressure in the boiler is increased to 2.5 kg, open the connecting pipe circulation valve between high-pressure boiler A and high...

Embodiment 3

[0033] Embodiment 3: a kind of purple waxy corn blanching and cooling process comprises the following steps:

[0034] The high-temperature and high-pressure sterilization process of purple black waxy corn includes a high-pressure boiler A and a high-pressure boiler B, which are connected by connecting pipes, and there are circulation valves on the connecting pipes; the operation steps are as follows:

[0035] Step 1: Close the hatch of the high-pressure boiler A, pressurize the pot to 2.2 kg, add 1.5 cubic meters of cold water, and heat the water to 120°C with steam; Step 2: Use high-temperature-resistant, non-toxic special plastic The vacuum-packed corn is put into a stainless steel cart, which is full of transparent holes, so that water can flow from all angles. The cart is pushed into the high-pressure boiler B, and the pressure in the boiler is increased to 2.2 kg, open the connecting pipe circulation valve between high-pressure boiler A and high-pressure boiler B to let t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com