Multifunctional Cylindrical Ore Sand Making Machine

A cylinder type sand making machine technology, applied in grain processing, etc., can solve problems such as power consumption, production capacity, equipment investment impact, etc., achieve obvious energy saving effect, large adjustment range, and small investment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

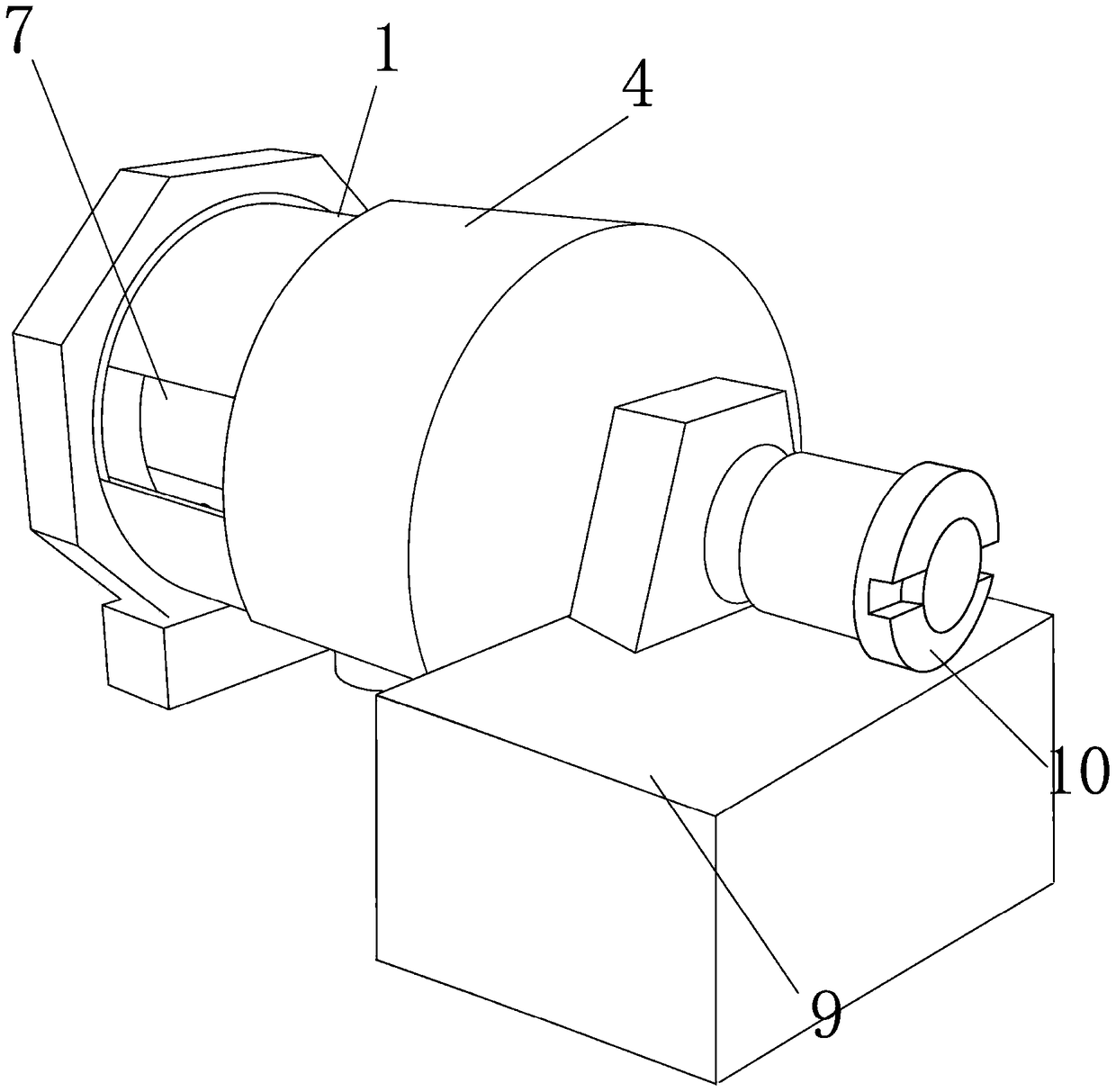

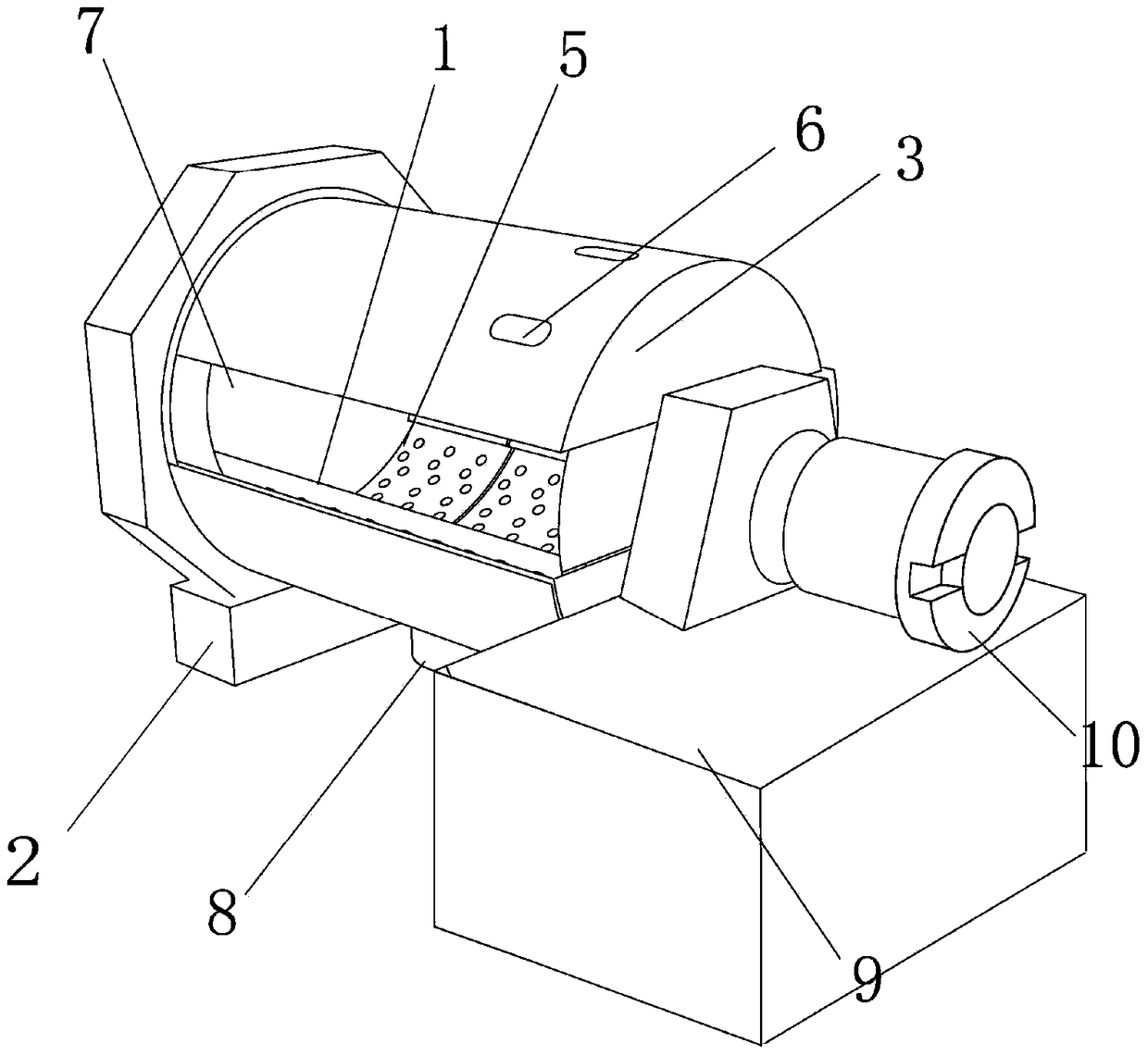

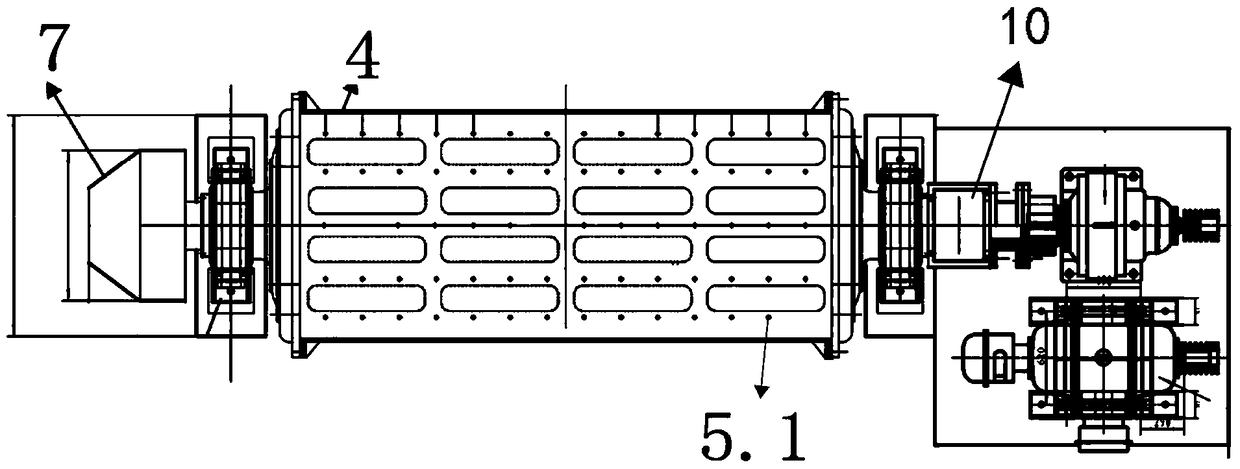

[0027] Such as Figure 1-4 , the multifunctional cylindrical ore sand making machine includes a sand making cylinder and a power unit, which are supported by a base 2 and a machine base 9 . The transmission device includes a transmission coupling connector 10, and a reducer, a frequency converter and a motor (not shown in the figure) connected with the transmission coupling connector 10. There are frosted spheres, and the frosted spheres can be grinding steel balls. The warehouse body 1 is provided with a liner, and the liner 5 is as Figure 4 As shown, sand discharge holes 5.1 are provided; and the connection relationship between the liner 5 and the bin body is a detachable connection. In this embodiment, the surface of the liner 5 in the bin body 1 is stepped or corrugated, and flat. The side of the bin body 1 is provided with a material inlet 7; the outer layer is also provided with a discharge bin 3, and the discharge bin is provided with a discharge port 6, and the disch...

Embodiment 2

[0029] In this embodiment, the difference from Embodiment 1 is that the discharge opening 6 is circular.

[0030] The following is the application description: The total power of the traditional sand making equipment motor is 513kw, which is not wear-resistant, and requires multiple conveyor belts, large and small transmission gears are easy to damage, and the steel balls of the accessories are worn out. Replace them every 1 to 2 months. Production cost: about 12 to 15 yuan;

[0031] However, this product is safe and wear-resistant, and there is no large or small transmission gear transmission, and the steel balls of the worn parts can be replaced once every year or 180-360 days. According to actual production estimates, the production cost per cubic sand is about 6-8 yuan, which is only 40%-45% of the production cost of other products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com