A double metal stamping die

A technology of stamping dies and doubles, which is applied in the field of doubles metal stamping dies, can solve the problems of low output, time-consuming and laborious metal stamping dies, and achieve the effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

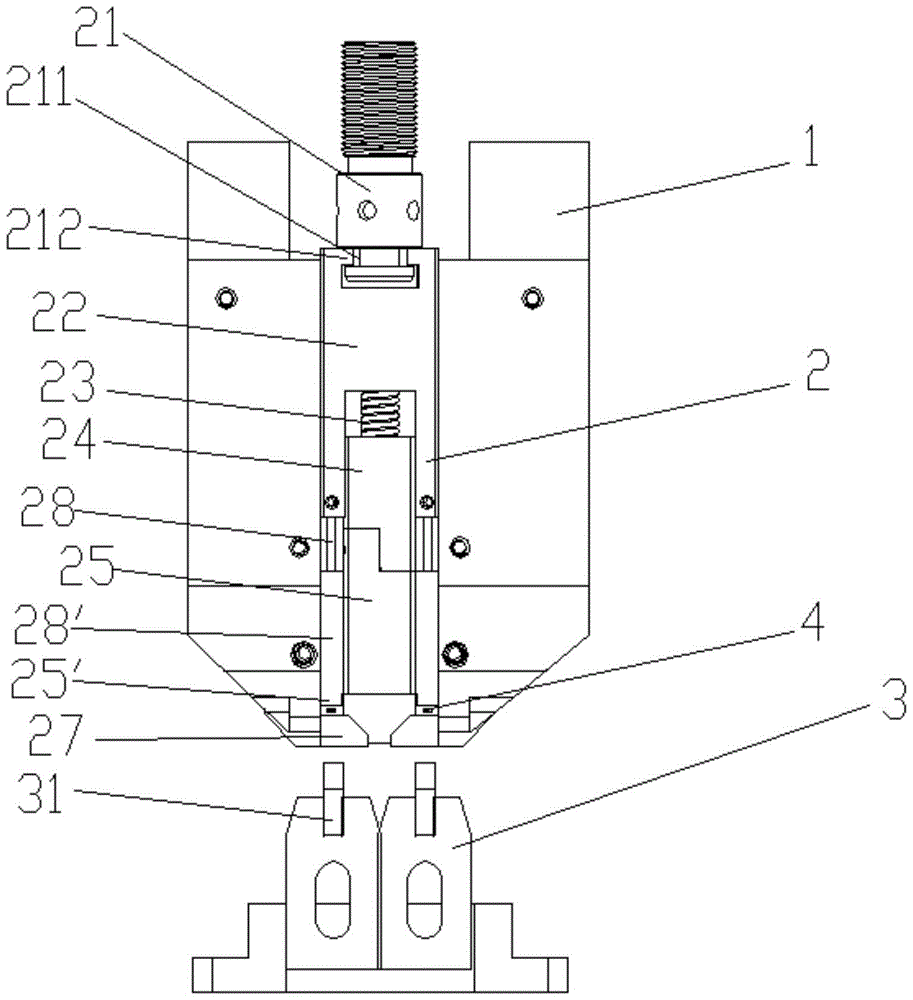

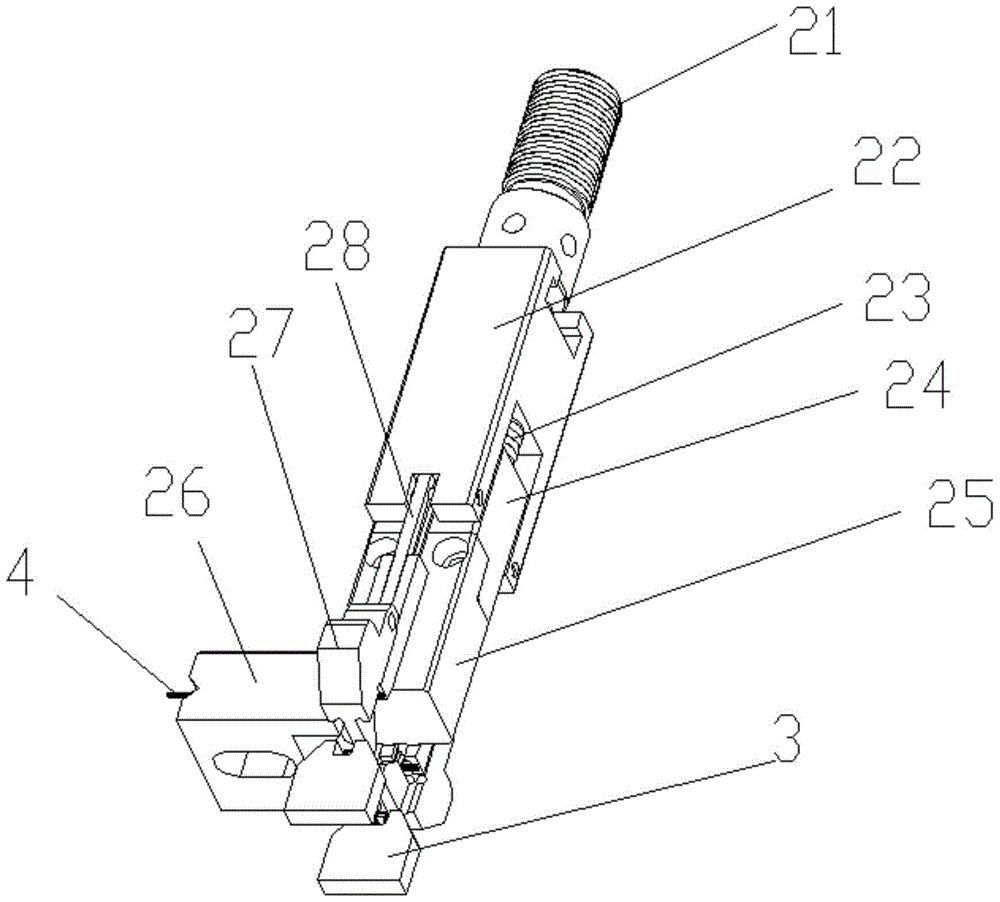

[0018] Such as figure 1 with figure 2 As shown, a double metal stamping die is assembled in a terminal machine for stamping and forming a copper strip 4 to form a U-shaped terminal, including a mold frame 1 fixedly installed on the terminal machine and a detachable mold frame 1 connected to the terminal machine head. The doubles mold 2, the doubles mold 2 is located in the mold base 1, the doubles mold 2 includes a hanging head 21 arranged in sequence from top to bottom, a slide block 22 detachably connected to the hanging head 21 through a slot structure, A pair of springs 23 are connected to the connecting block 24 of the slide block 22, the cutting and forming knife seat 25 fixedly connected to the connecting block 24, the copper strip feeding block 26 that is arranged on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com