Pneumatic double-bit bench drill capable of realizing automatic feeding

A technology of automatic feeding and double-head bench drilling, which is applied in the direction of driving device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of slow processing efficiency and increased process difficulty, so as to improve work efficiency, Simplified and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

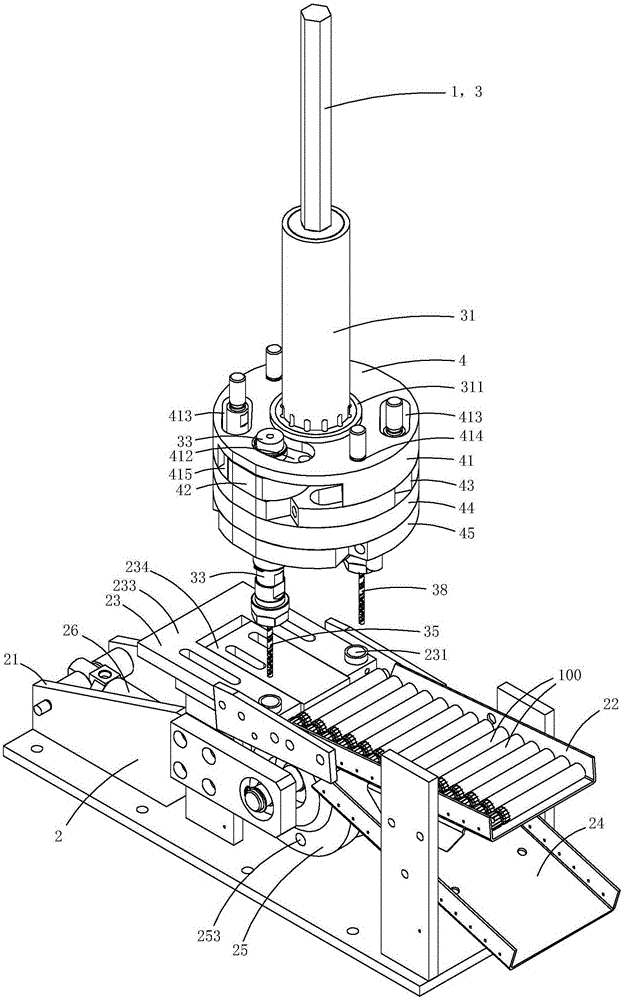

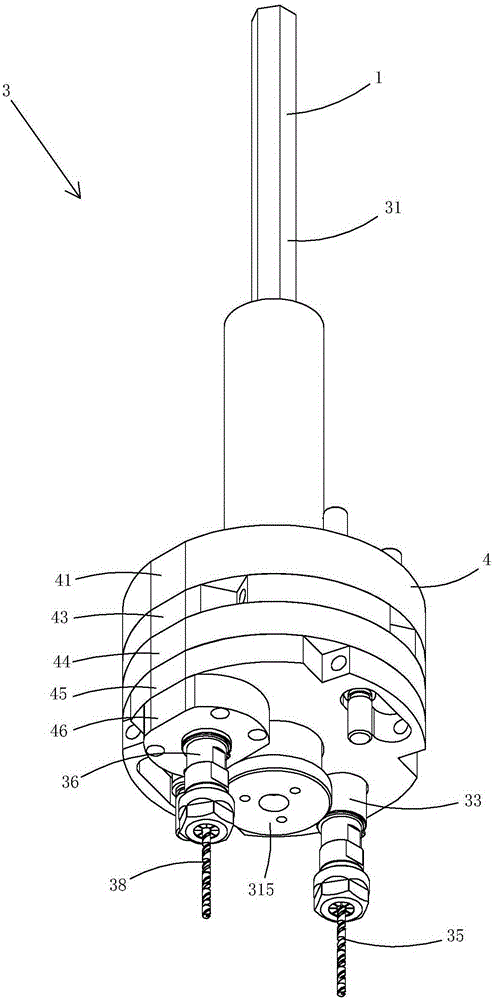

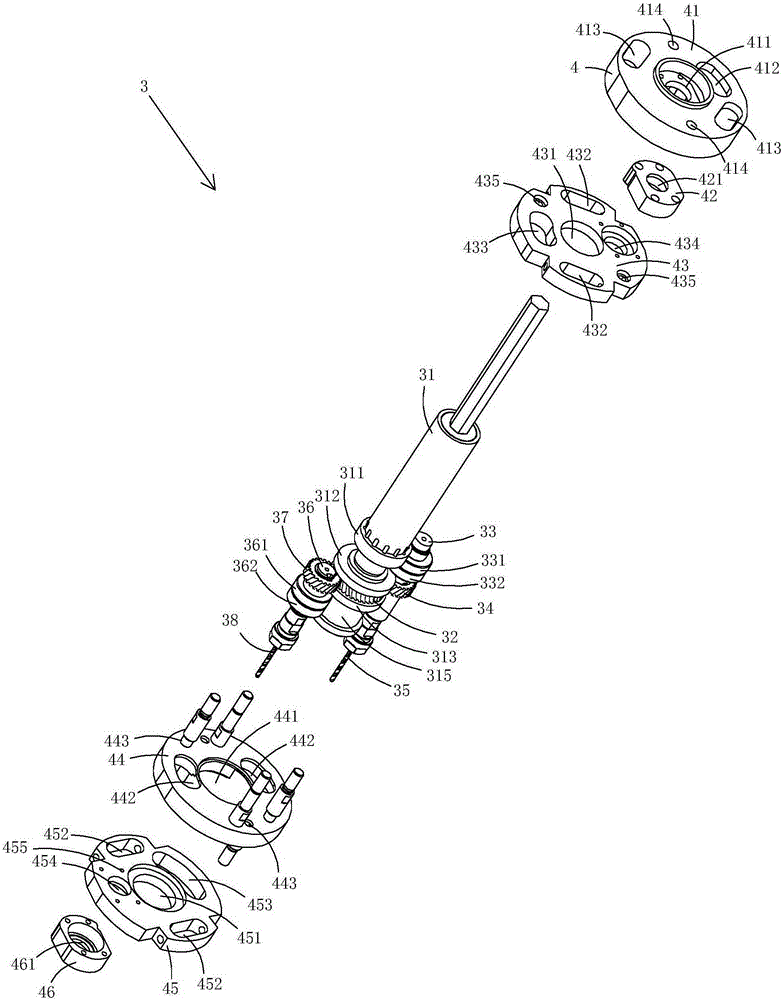

[0022] Figure 1 to Figure 12 One specific embodiment of the invention is shown.

[0023] This embodiment is a pneumatic automatic feeding type double-headed bench drill, see Figure 1 to Figure 12 As shown, the bench drill includes a bench drill body 1 and a feeding mechanism 2 .

[0024] The bench drill body 1 includes a double drill mechanism 3 and a lifting mechanism (not shown in the figure) for driving the double drill mechanism 3 to move up and down.

[0025] The double drill mechanism 3 comprises a mounting plate 4, a main shaft 31 which is rotatably arranged at the center of the mounting plate, a driving wheel 32 which is fixed on the main shaft, a first transmission shaft 33 which is rotatably disposed on the mounting plate, and which is fixedly arranged on the upper end of the first transmission shaft. The first driven wheel 34, the first drill bit 35 that is arranged on the lower end of the first transmission shaft, the second transmission shaft 36 that is rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com