A new compound broach

A new type of tie rod technology, applied in the direction of broach, broaching machine, metal processing equipment, etc., can solve the problem of unfinished, and achieve the effect of improving the vertical part, improving the work efficiency, and improving the verticality of the upper and lower parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

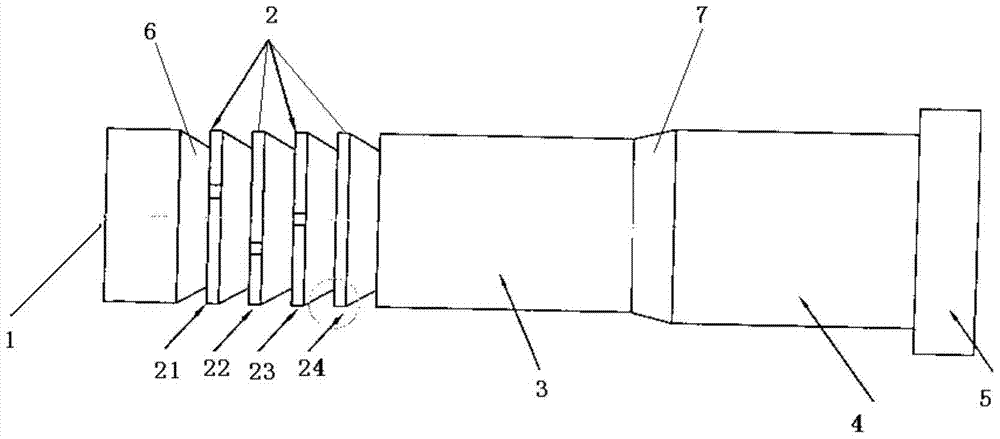

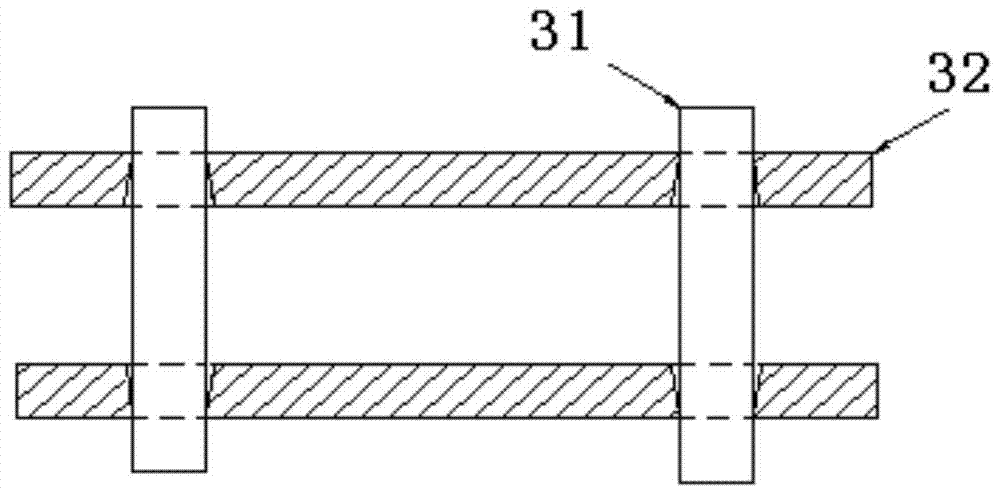

[0028] like figure 1 As shown: the composite broach of the present invention includes a punching nail 1, a tooth 2, a pull rod 3, a broach positioning part 4 and a broach tail 5, and a diameter from the punching nail is set between the punching nail 1 and the tooth 2 1. The first circular frustum connection part 6 that tapers toward the direction of the tooth 2. A second circular frustum connection whose diameter becomes larger from the pull rod 3 to the broach positioning part 4 is provided between the pull rod 3 and the broach positioning part 4. part 7, the pull rod 3 is arranged between the tooth 2 and the second round table connection part 7, the broach positioning part 4 is arranged between the second round table connection part 7 and the broach tail part 5, and the tooth 2 includes a diameter larger than the punching hole The punching teeth with an initial diameter smaller than the punching target diameter and the repairing teeth with a diameter equal to the punching ta...

Embodiment 2

[0043] As a preferred embodiment, figure 1 The compound broach shown has four teeth, that is, the tooth 2 includes a first tooth 21, a second tooth 22, a third tooth 23 and a fourth tooth 24, wherein the first tooth 21 and the second tooth 22 are punching teeth, The third tooth 23 and the fourth tooth 24 are repairing teeth, wherein the diameter of the first tooth is 0.1mm-0.15mm larger than the diameter of the punching nail, and the diameter of the second tooth is 0.1mm-0.1mm larger than the diameter of the first tooth. 0.15mm, the diameter of the punching nail 1 is equal to the initial diameter of the punching hole. In this embodiment, the processing from the initial parameters of the punching to the target parameters is completed by three broaching of the punching nail 1, the first tooth 21 and the second tooth 22, and then the hole repair is realized by the third tooth 23 and the fourth tooth 24, Further improve the up and down verticality of the punched inner hole cylind...

Embodiment 3

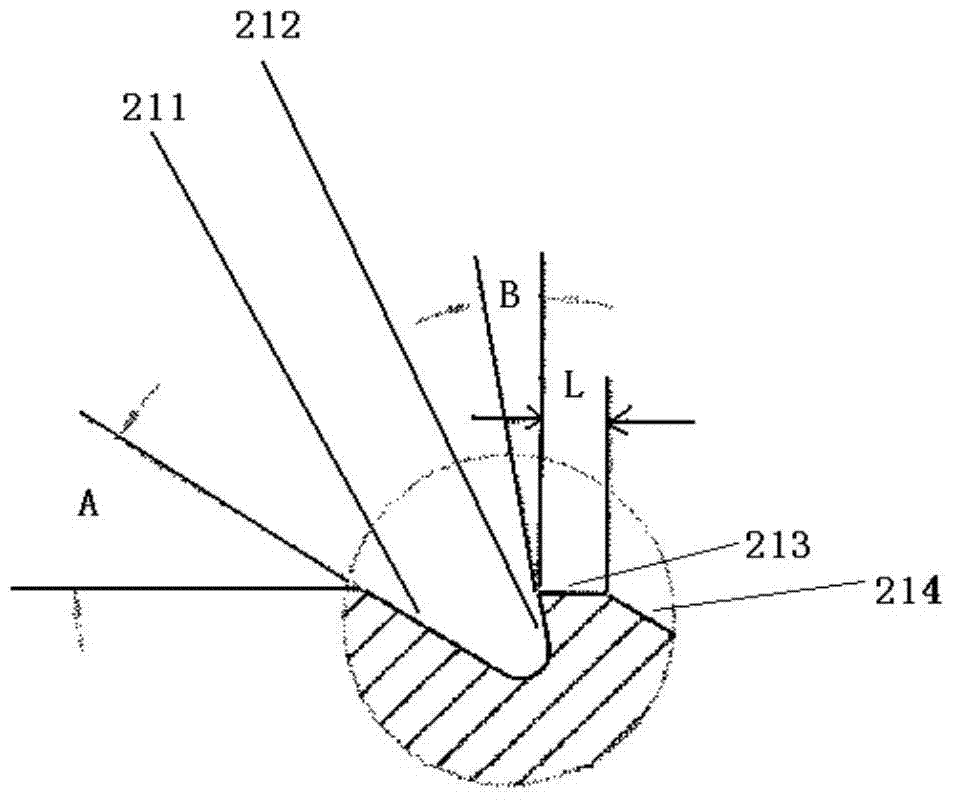

[0049] like figure 2 As shown, the punching tooth and the repairing tooth both include a first base surface 211, a second base surface 212, a third base surface 213 and a fourth base surface 214, wherein the distance between the first base surface 211 and the horizontal plane The included angle is A, the included angle between the second base surface 212 and the vertical surface is B, the horizontal plane and the vertical surface are perpendicular to each other, and the first base surface 211 and the second base surface 212 are smoothly connected by an arc surface, A groove is formed at the arc-shaped surface between the first base surface 211 and the second base surface 212; the second base surface 212 and the third base surface 213 form tooth tips at the intersection; the width of the third base surface 213 is L , the fourth base surface 214 is inclined downward from the third base surface 213 at a position whose distance from the tooth tip is equal to the width of the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com