Automatic welding device for stainless steel water segregator

A technology of automatic welding and water separator, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of false welding, welding failure, enterprise loss, etc., and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

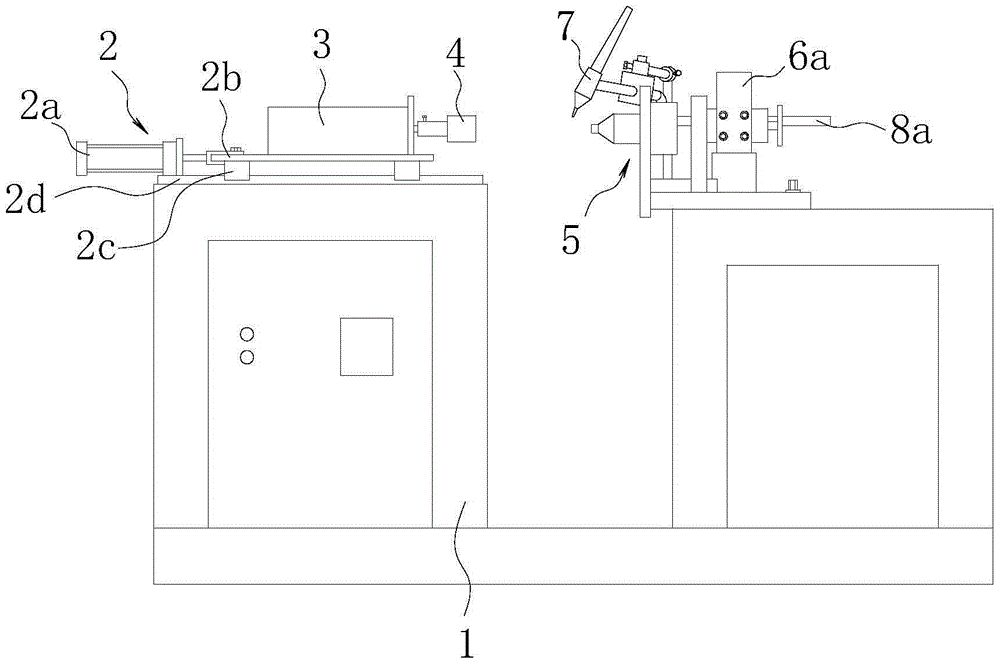

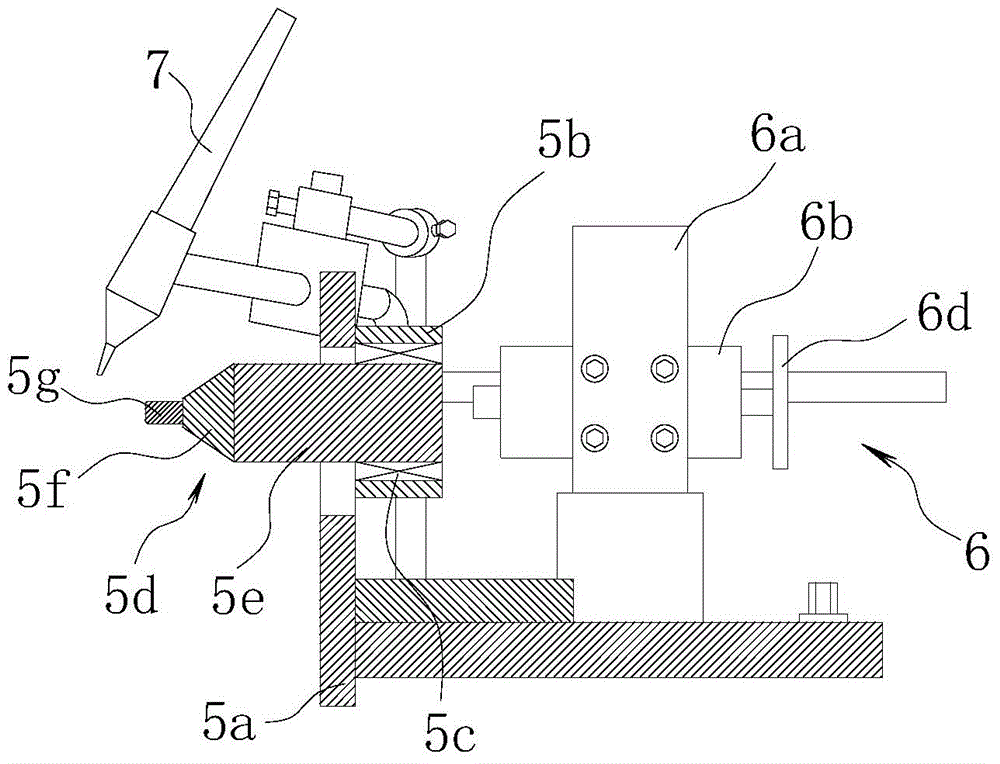

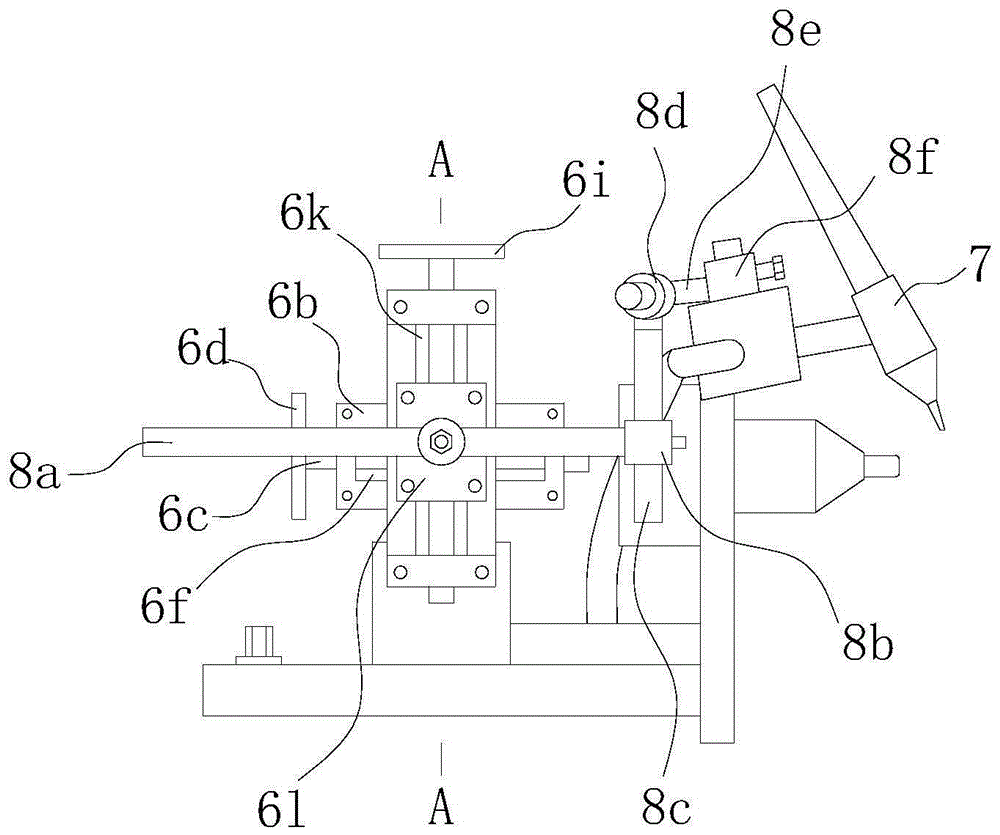

[0018] refer to Figure 1 to Figure 4 As shown, an automatic welding device for a stainless steel water separator of the present invention includes a frame 1 on which a horizontal drive unit 2 is provided. Preferably, the horizontal drive unit 2 consists of a horizontally arranged cylinder 2a, and The sliding plate 2b connected to the free end of the telescopic rod of the cylinder 2a, the sliding block 2c arranged on the sliding plate 2b, and the guide rail 2d arranged on the frame 1 and matched with the sliding block 2c are composed; the horizontal drive unit 2 is provided with The rotary drive mechanism 3, preferably, the rotary drive mechanism 3 is a rotary motor, and the rotary drive mechanism 3 is arranged on the sliding plate 2b. The horizontal position of the rotary drive mechanism 3 can be adjusted via the horizontal drive unit 2 . A control unit is provided on the frame 1, and both the horizontal drive unit 2 and the rotary drive mechanism 3 are connected to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com