Spoke lathe clamp

A technology for lathe fixtures and spokes, which is applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems that affect the accuracy of spoke processing, low thread positioning accuracy, and loose workpieces, so as to improve production efficiency and shorten clamping time , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

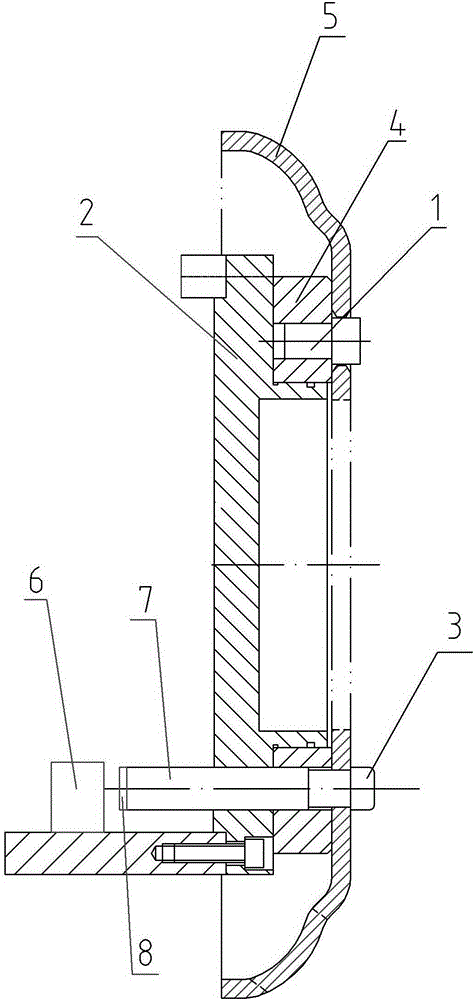

[0013] The reference signs in the drawings of the description include: spherical positioning pin 1 , clamp body 2 , protrusion 3 , positioning plate 4 , wheel spoke 5 , electromagnet 6 , pull rod 7 , and magnet 8 .

[0014] The embodiment is basically as attached figure 1 Shown: a fixture for a spoke lathe, including a clamp body 2 and a positioning disc 4, wherein the positioning disc 4 is fixed on the clamp body 2, and also includes an electromagnet 6 and a pull rod 7, the electromagnet 6 is arranged on one side of the clamp body 2, and the pull rod 7. A magnet 8 that cooperates with the electromagnet 6 is installed at one end; There are four spherical positioning pins 1 on the positioning disk 4 that match the spoke ball and socket holes, because the surface of the spoke ball and socket holes is a curved surface, one end of the spherical positioning pin 1 is spherical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com