Bi-color die

A technology of two-color mold and mold cavity, applied in the field of two-color mold, can solve the problems of short mold maintenance cycle, complex ejection mechanism and high maintenance cost, and achieve the effect of reducing processing difficulty and complexity, extending maintenance period and reducing maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

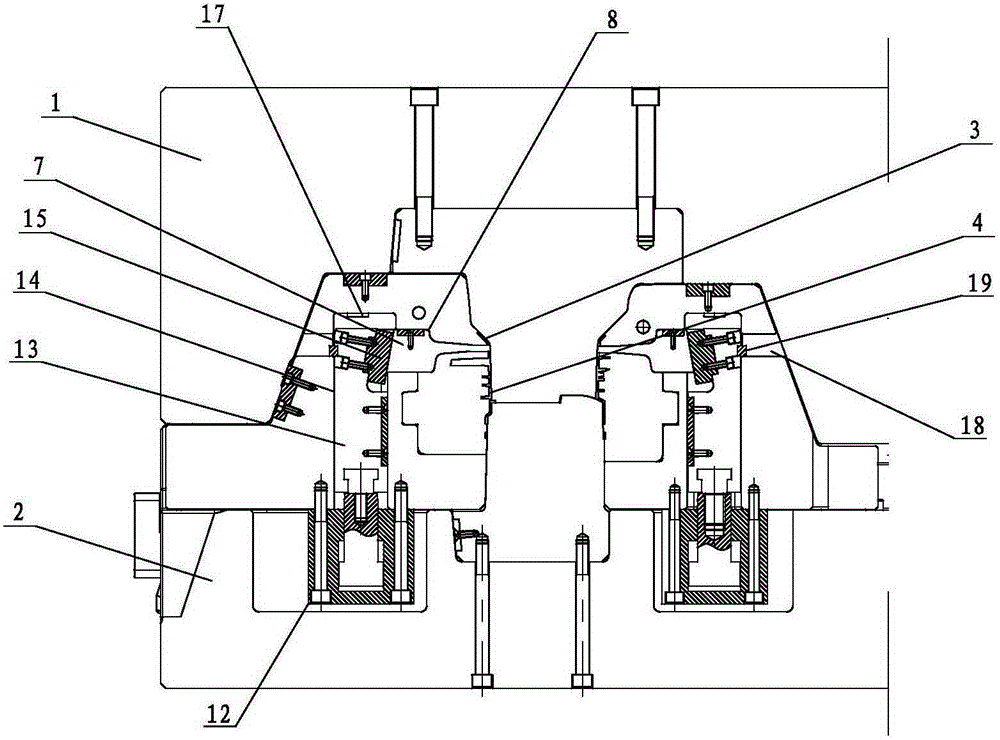

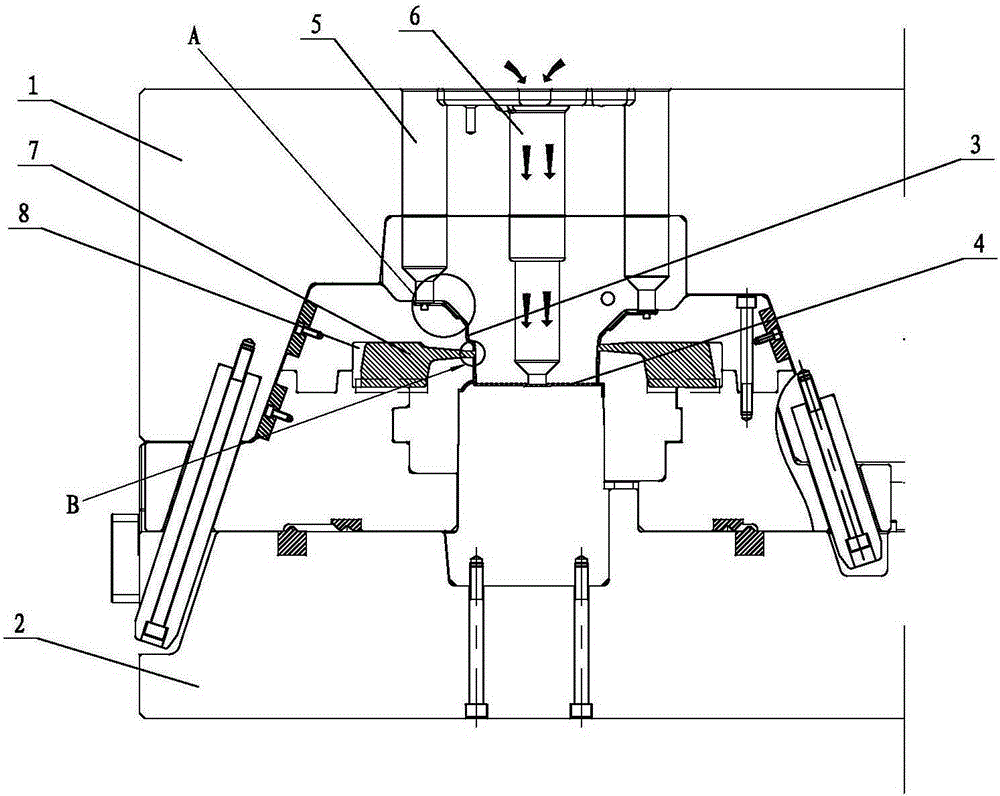

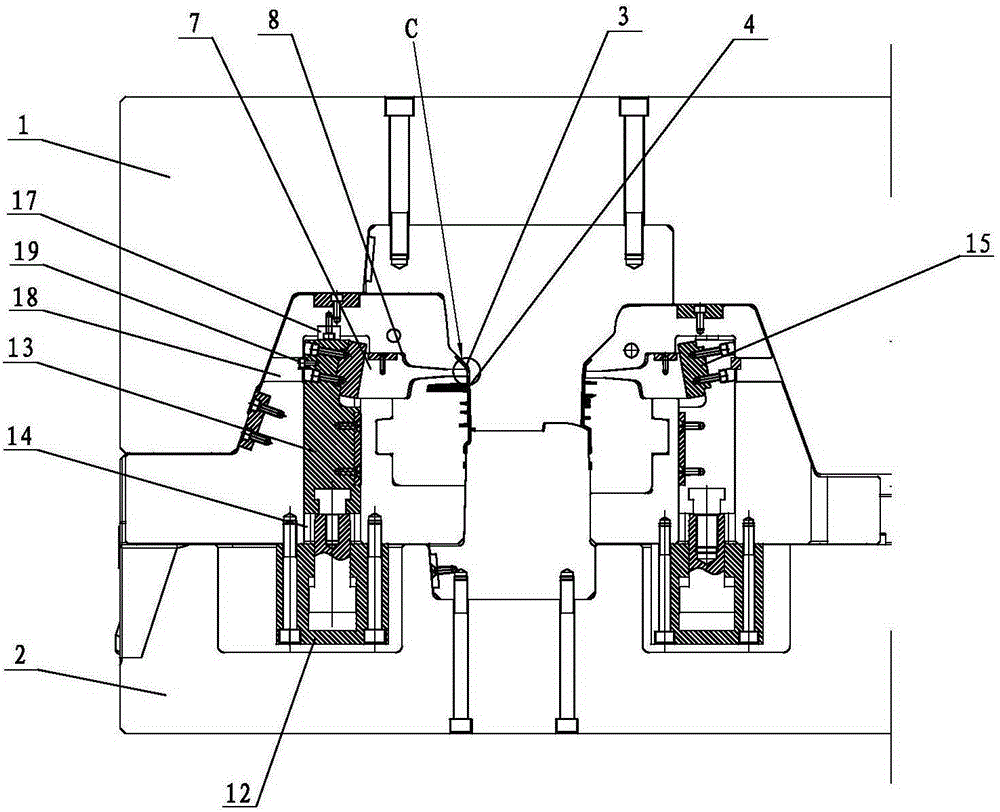

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Shown, a kind of two-color mold, it comprises fixed mold 1 and movable mold 2 (certainly also comprises other components, but because do not relate to the invention point of the present invention, so do not repeat them here), described fixed mold 1 After closing with the movable mold 2, a mold cavity is formed, and the mold cavity is divided into a soft rubber cavity 3 and a hard rubber cavity 4, and the fixed mold 1 is provided with a soft rubber gate 5 and a hard rubber gate 6 , and the soft rubber gate 5 and the hard rubber gate 6 communicate with the soft rubber mold cavity 3 and the hard rubber mold cavity 4 respectively, and the movable mold 2 is slidably connected with the soft rubber mold cavity 3 and the hard rubber mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com