Top cover decoration strip installation buckle

A decorative strip and buckle technology, which is applied in the direction of transportation, packaging, and vehicle parts, can solve problems such as failure to connect the buckle, dislocation of the installation buckle, and insecurity, so as to facilitate installation and adjustment, make the installation position reasonable, and compensate for relative errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

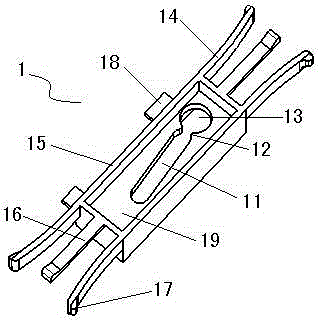

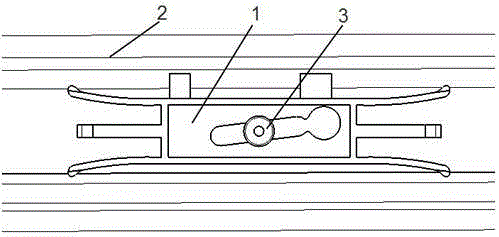

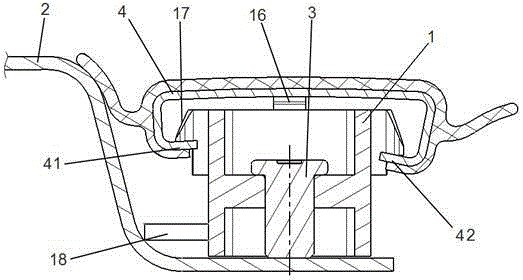

[0011] Example: A preferred embodiment of the present invention is as follows. The buckle is installed on the top cover decorative strip, the buckle body 1 is provided with a mounting hole 13, the diameter of the mounting hole 13 is 2 mm larger than the diameter of the big head of the rivet 3; a positioning chute 11 extends from the side of the mounting hole 13, and the positioning chute 11 It is an oblong hole, the diameter of which is 0.4mm larger than the diameter of the small head of rivet 3, and the length is as long as possible. The projected length of its length in the transverse direction of the vehicle must be greater than the cumulative tolerance of the position of rivet 3, so as to compensate for the rivet caused by the welding process of the body. 3 The position is offset in the lateral direction of the vehicle. The limiting boss 12 provided between the positioning chute 11 and the mounting hole 13 can prevent the buckle body 1 from slipping out of the rivet 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com