Lightweight driver enclosure with frame arranged inside

A lightweight, skeleton technology, applied in the field of auto parts, can solve the problems of low assembly work efficiency, complex installation results, environmental protection not up to standard, etc., to achieve the effect of novel and unique shape, simple and elegant appearance, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

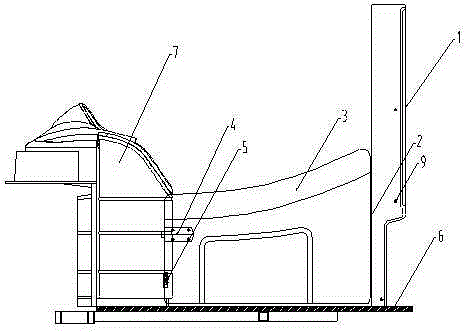

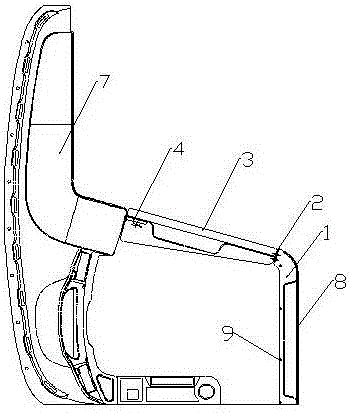

[0013] Depend on figure 1 , figure 2 Known, a kind of built-in framework lightweight driver surrounds, is made up of surround assembly 1, stainless steel hinge 2, surround door 3, door lock 4, limit block 5, surround assembly 1 is provided with a plurality of mounting holes 9, through bolt Pass through the mounting hole 9 to complete the fixed connection with the body floor 6 and the side wall. The whole enclosure can be fixed on the body floor 6 and the side wall because of its light weight and only needs a few bolts to complete the fixed connection with the whole vehicle. The assembly is convenient and simple. The stainless steel hinge 2 is fixed on one side of the surrounding door 3 with bolts, the door lock 4 and the limit block 5 are fixed on the other side of the surrounding door 3, and the surrounding door 3 is movably connected to the surrounding assembly 1 through the stainless steel hinge 2; 7 and the surrounding door 3 are limitedly connected with the door lock 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com