A power output system of a small bicycle

A power output and power system technology, applied in bicycles, two-wheeled bicycles, motorcycles, etc., can solve the problems of lack of protection of power output systems, and achieve the effects of increasing connection stability, small size and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

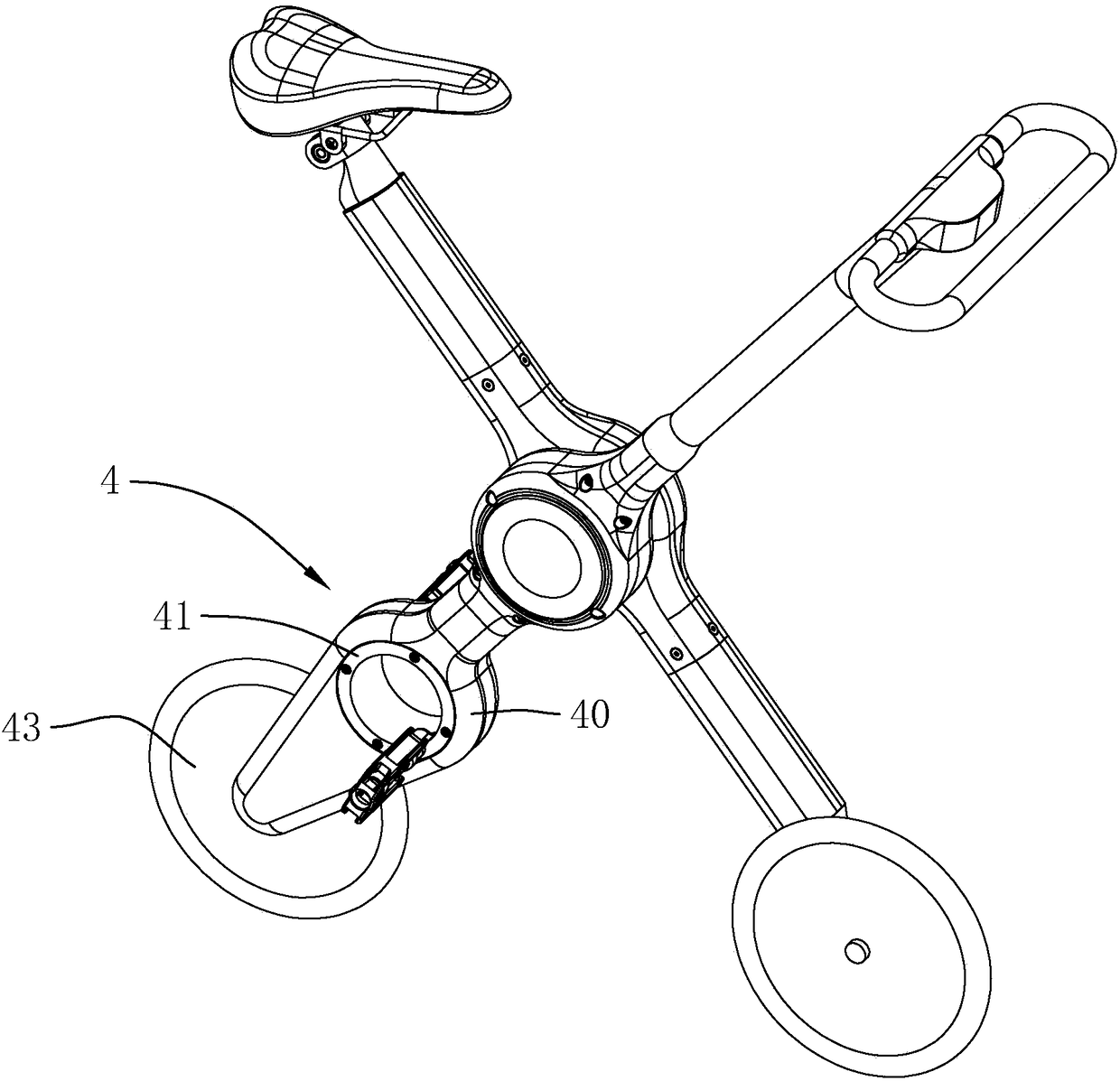

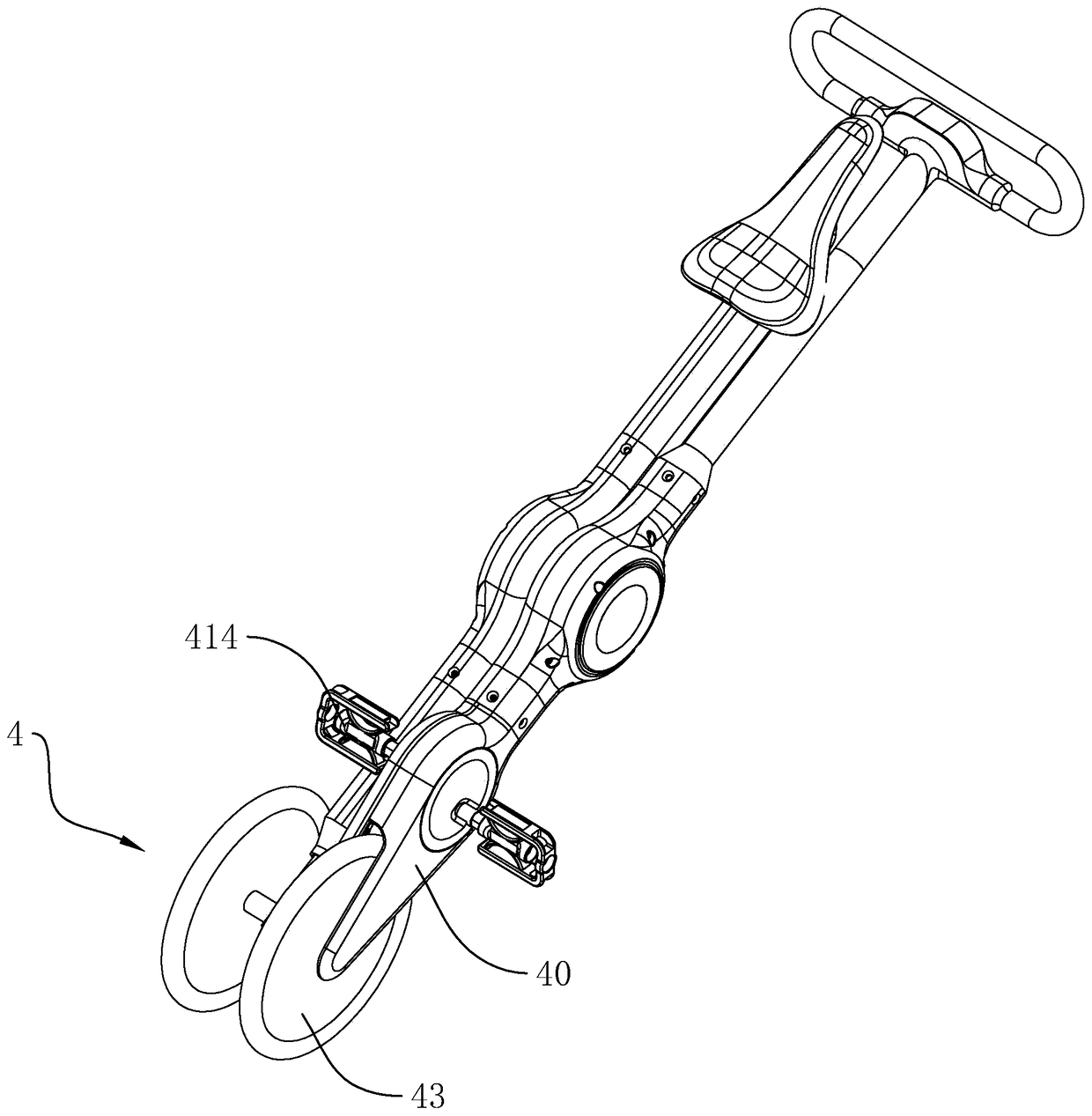

[0037] Such as Figures 1 to 8 The power output system of a small bicycle is shown. The small bicycle with this power output system can be a fixed bicycle or a folding bicycle, and its folding methods are various. The folding method of the folding bicycle in this embodiment The method of turning and folding is adopted, that is, the shape of the body is "X" when unfolded, and the shape of the body is "I" when folded.

[0038] The power output system of the miniature bicycle comprises a power input mechanism 41 and a rear wheel frame 40, the rear wheel frame 40 is a hollow shell, the power input mechanism 41 is arranged inside the rear wheel frame 40, and the power input mechanism 41 includes a turret 410, a crankshaft 411, flywheel 412 and chain 413, turret 410 is circular columnar, turret 410 is embedded in the rear wheel frame 40 and is connected with the rotation of rear wheel frame 40, and chain 413 connects crankshaft 411 and flywheel 412, connects on flywheel 412 The rea...

Embodiment 2

[0047] Compared with Embodiment 1, the only difference between this embodiment and Embodiment 1 is that the power of this embodiment uses electric power as the power input source, that is, the bicycle in this embodiment is an electric power-assisted bicycle.

[0048] The power input mechanism 41 comprises a motor, the motor is fixed on the rear wheel frame 40, the motor is connected with the turret 410, and the power supply connected to the motor adopts a lithium battery as a power supply, and the inside of the vehicle frame is hollow, and the lithium battery can be fixed on a hollow vehicle. Inside the frame, power is provided for the motor. Users can use electricity to propel the bicycle forward, effectively relieving the fatigue caused by riding.

Embodiment 3

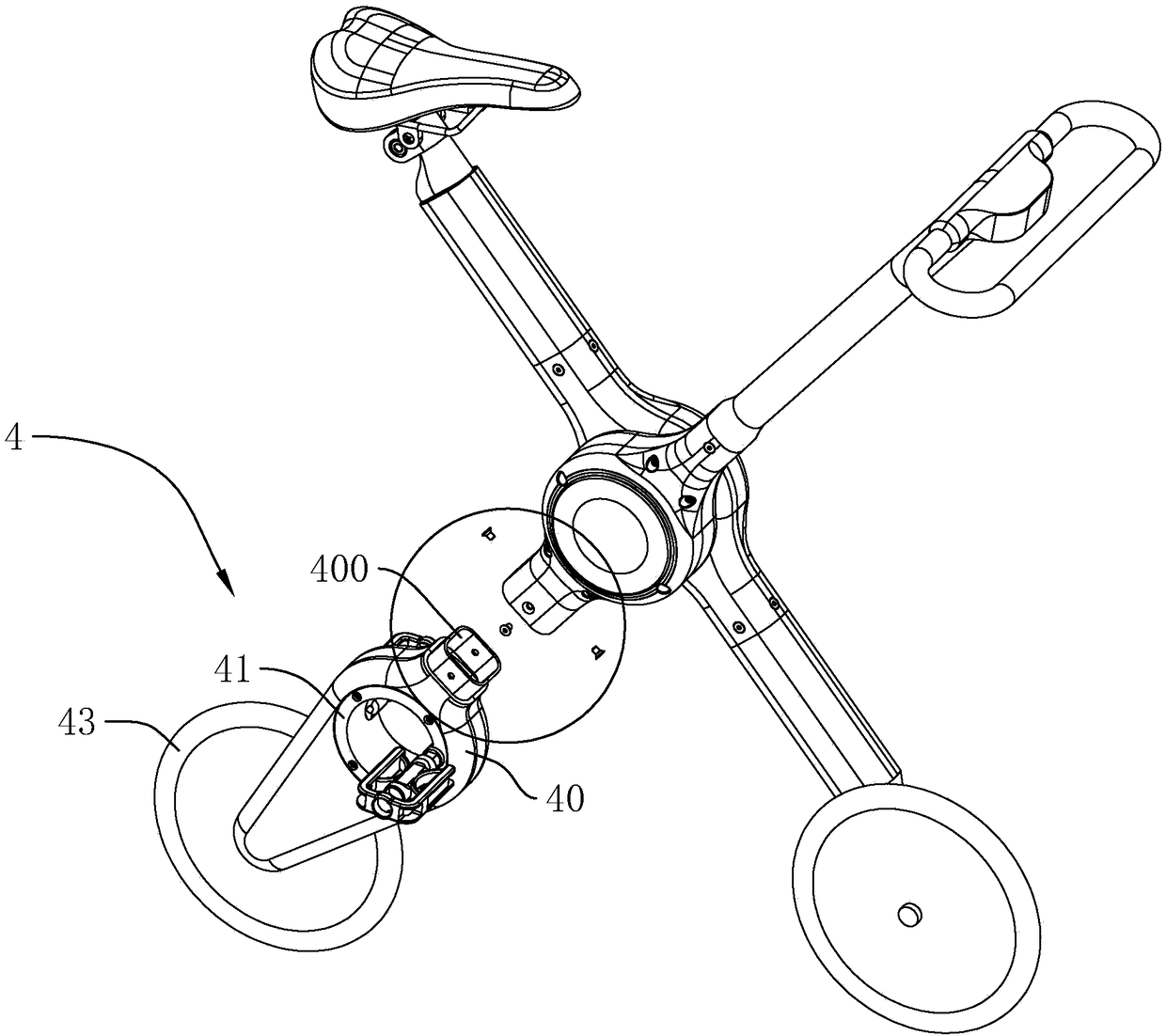

[0050] Compared with Embodiment 1, this embodiment differs in that the connection mode between the rear wheel frame 40 and the bicycle frame is a detachable connection, and the end of the rear wheel frame 40 facing the frame is provided with a step socket 400, and the step cover The port 400 is provided with a threaded hole 4000, and the stepped socket 400 is used to socket the rear wheel frame 40 of the rear wheel assembly 4 on the vehicle frame. The wheel assembly 4 is fixed to the vehicle frame.

[0051] The cross-sections of the rear wheel frame 40 at the stepped socket 400 and the stepped socket 400 are rectangular with rounded edges, and the two are equidistantly arranged. The rectangular shell is relatively easy to manufacture, has high structural strength, and is not easily deformed under pressure, while the rounded rounded edge makes the surface of the rear wheel frame 40 smoother and prevents scratches such as scratches from being left.

[0052] When the rear wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com