Corrugated paper packaging box for small-size ball product and manufacturing method of corrugated paper packaging box

A manufacturing method and technology of corrugated paper, applied to packaging devices for ball items, corrugated paper packaging boxes for small-sized ball products and its manufacturing field, can solve the problems of low final use rate, low recycling rate, and high labor cost. , to achieve the effects of simple molding process and easy operation, compact structure, and simple production and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

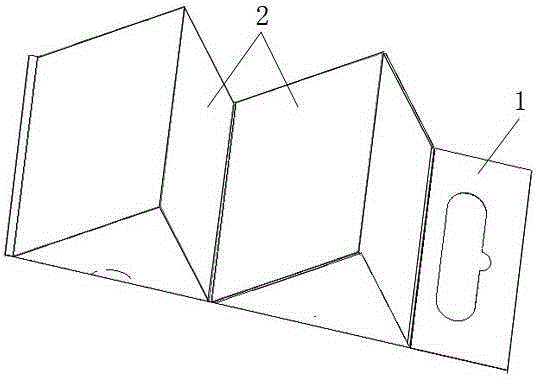

[0021] A corrugated paper packaging box for small-sized ball products includes a hanging part 1 and a plurality of triangular prism boxes 2, and the hanging part 1 and the triangular prism boxes 2 are formed by folding integral corrugated paper.

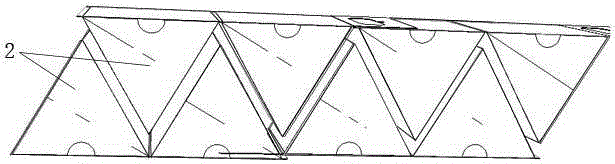

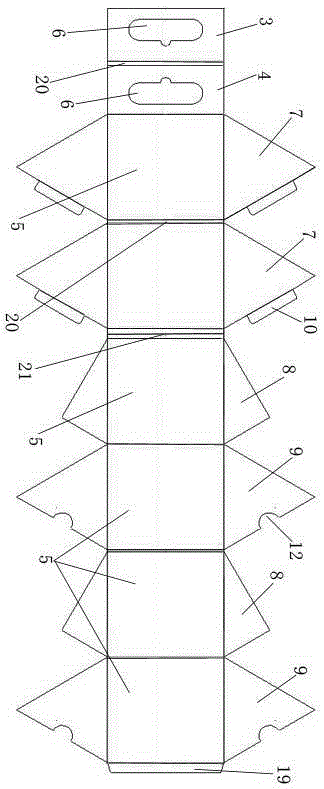

[0022] Such as figure 1 The shown corrugated packaging box has two triangular prism boxes 2, and its unfolded schematic diagram is as follows: image 3 As shown, wherein, the three sides of each triangular prism box body 2 are all folded by three square plates 5, and the upper and lower end faces of the triangular prism box body 2 are provided with sealing devices, and the sealing devices are formed by respectively connecting with the three square plates 5 The vertically connected first sealing plate 7, the second sealing plate 8 and the third sealing plate 9 are composed of the first sealing plate 7, the second sealing plate 8 and the third sealing plate 9 are triangular in shape, and the three are formed from a triangular prism Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com