Elevator arrangement structure

A technology for arranging structures and elevators, applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of poor car braking comfort, reduced hoistway space utilization, and large wear of guide rails and guide shoes. , to achieve the effect of stable operation of the car, compact elevator layout, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

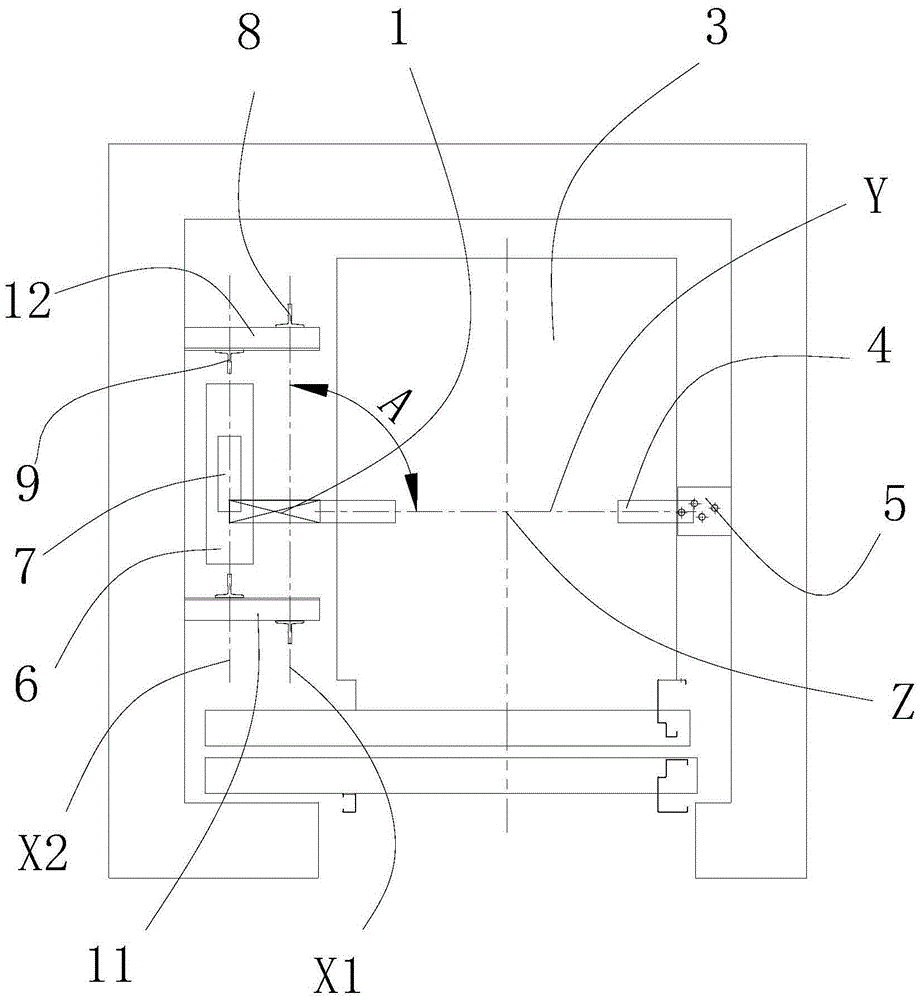

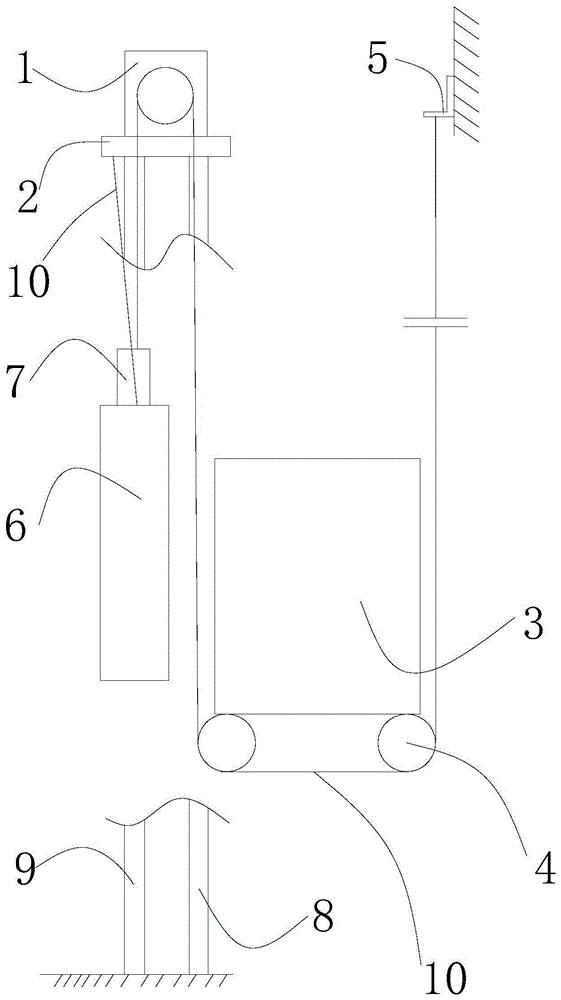

[0021] see figure 1 with 2 , an elevator layout structure, including a traction machine 1, a traction machine frame 2, a car 3, a pair of car anti-sheaves 4 respectively arranged on the left and right sides of the car 3, and a car side rope end fixing member 5. A counterweight 6 located on one side of the car 3 , a counterweight reversing sheave 7 arranged on the counterweight 6 , a pair of car guide rails 8 , a pair of counterweight guide rails 9 and a traction rope 10 . In this embodiment, a pair of car reversing sheave 4 is located at the bottom of the car 3 . In other embodiments, a pair of car reversing sheaves 4 can also be arranged on the top of the car 3 .

[0022] Wherein, a pair of car guide rails 8 and the pair of counterweight guide rails 9 are all located on the same side of the car 3, as figure 1 is the left side of car 3. The central line X1 of a pair of car guide rails 8 is parallel to the central line X2 of a pair of counterweight guide rails 9 . The trac...

Embodiment 2

[0027] The elevator arrangement structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the acute angle A is 60°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com