Toughening furnace for manufacturing tempered glass

A technology of tempering glass and tempering furnace, which is applied in the direction of glass tempering, glass manufacturing equipment, glass transportation equipment, etc., to achieve the effect of strengthening automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

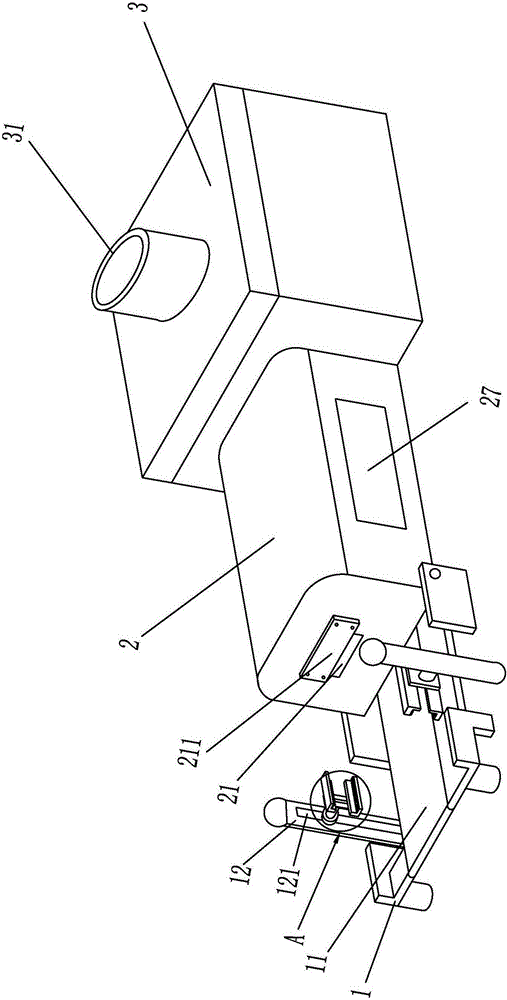

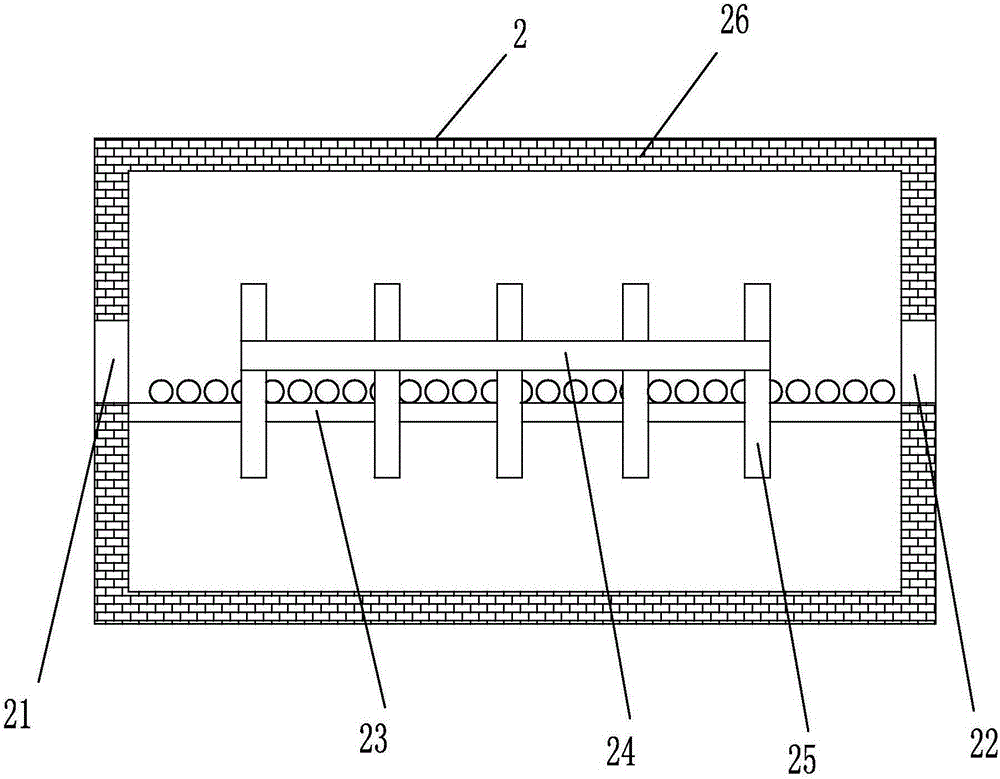

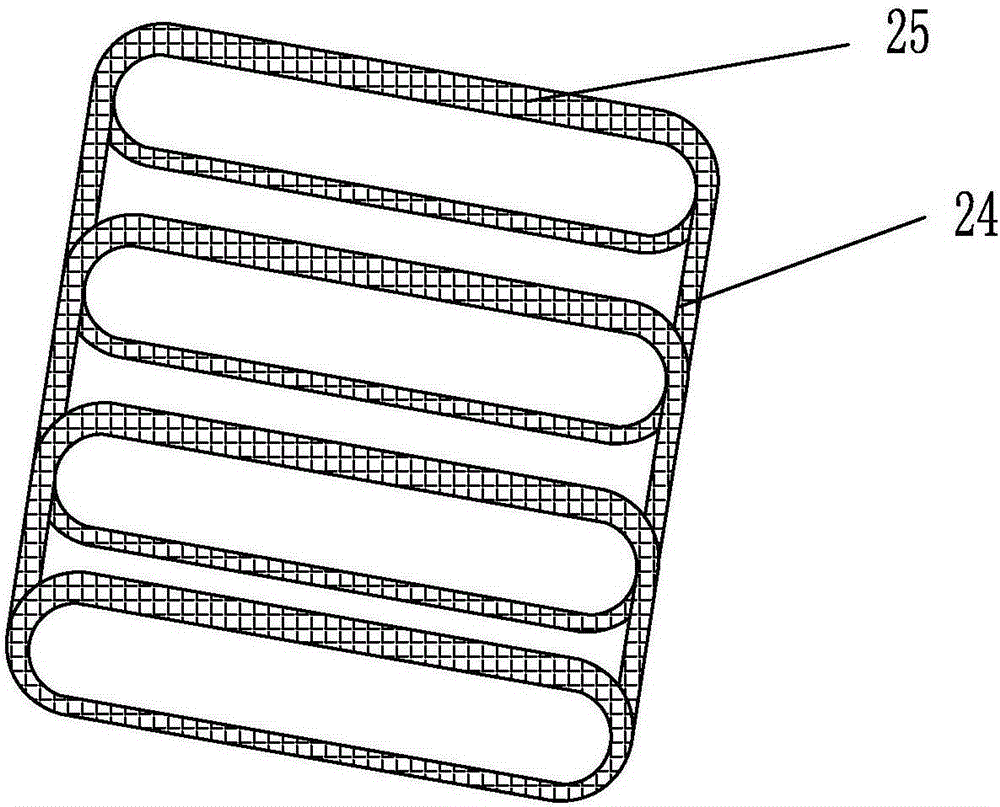

[0026] Such as Figure 1 to Figure 5As shown, a tempering furnace for making tempered glass includes a transmission mechanism, a heating chamber 2 and a cooling chamber 3, the heating chamber 2 is located between the transmission mechanism and the cooling chamber 3, and the transmission mechanism includes a conveying platform 1 and a lifting and picking mechanism , The conveying table 1 is provided with a conveyor belt 11, and the conveyor belt 11 cooperates with the lifting and picking mechanism to transport the glass materials in a stable and orderly manner. Both sides of the conveying table 1 are provided with fetching grooves (not marked in the figure), and a lifting and fetching mechanism is provided in the fetching groove. Lifting column 12 is provided with moving rail 121, and telescopic arm 13 is connected in moving rail 121, and telescopic arm 13 is fixed with grasping clip 14, and the inner side of grabbing clip 14 is provided with rubber pad 141, because rubber pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com