A kind of microemulsion system and method for extraction and separation of nickel and lithium

A microemulsion and system technology, applied in the direction of improving process efficiency, etc., can solve problems such as long extraction time, long stripping process, and many emulsions, and achieve the effects of reducing raw material types, facilitating experimental preparation, and fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

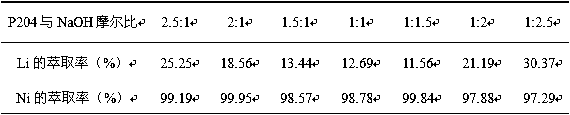

[0012] Saponification: Add 22 mL of NaOH solution with a concentration of 1.0 mol / L to 5.0 mL of P204, mix well, place in a constant temperature shaker in a water bath, shake at a frequency of 150 rpm, shake at room temperature for 30 minutes, take it out and let it stand for 12 hours .

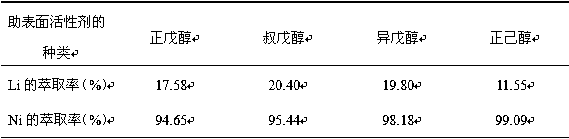

[0013] Preparation of microemulsion: Saponification P204, n-hexanol, and n-heptane are mixed in a volume ratio of 0.8:3:7, and the mixture is ultrasonicated at room temperature for 30 minutes, and then left to stand for 24 hours to obtain a transparent microemulsion system.

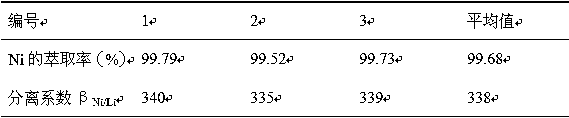

[0014] Extraction and separation: Take 5.0 mL of the above-mentioned microemulsion, mix it according to the milk-water ratio of 1:8 (the concentrations of nickel ions and lithium ions in the outer aqueous phase are 100 mg / L and 80 mg / L, respectively), after mixing evenly, Place in a constant temperature oscillator in a water bath with an oscillation frequency of 150rpm, shake at room temperature for 8 minutes, take it ou...

Embodiment 2

[0019] Saponification: Add NaOH solution with a concentration of 1.0 mol / L to P204, the molar ratio of P204:NaOH solution is: 1:1.5, mix well and place in a constant temperature oscillator in a water bath with an oscillation frequency of 150 rpm, shake at room temperature for 30 Minutes, take it out and let it stand for 12 hours.

[0020] Preparation of microemulsion: Saponification P204, n-hexanol, and n-heptane are mixed in a volume ratio of 0.5:2:6, and the mixture is ultrasonicated at room temperature for 30 minutes, and then left to stand for 24 hours to obtain a transparent microemulsion system.

[0021] Extraction and separation: Take 5.0 mL of the above-mentioned microemulsion and mix it according to the emulsion water ratio of 1:7 (wherein the concentrations of nickel ions and lithium ions in the external aqueous phase are 100 mg / L and 80 mg / L respectively), after mixing evenly, Place in a constant temperature oscillator in a water bath with an oscillation frequency o...

Embodiment 3

[0023] Saponification: Add NaOH solution with a concentration of 1.0 mol / L to P204, the molar ratio P204:NaOH solution is: 1:2, mix well and place in a constant temperature oscillator in a water bath, the oscillation frequency is 150 rpm, and shake at room temperature for 30 Minutes, take it out and let it stand for 12 hours.

[0024] Preparation of microemulsion: Saponified P204, n-hexanol, and n-heptane are mixed in a volume ratio of 1:4:8, and the mixture is ultrasonicated at room temperature for 30 minutes, taken out and left to stand for 24 hours to obtain a transparent microemulsion system.

[0025] Extraction and separation: Take 5.0 mL of the above-mentioned microemulsion, mix it according to the milk-water ratio of 1:9 (the concentrations of nickel ions and lithium ions in the external aqueous phase are 100 mg / L and 80 mg / L, respectively), after mixing evenly, Place in a constant temperature oscillator in a water bath with an oscillation frequency of 150 rpm and shake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com