Wire unloading device of hank reeling machine

A twisting machine and twisting technology, applied in other manufacturing equipment/tools, textiles and papermaking, manufacturing tools, etc., can solve the problems of difficult operation, cumbersome work, labor-intensive, etc., and achieve the goal of reducing labor intensity and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the specific embodiments.

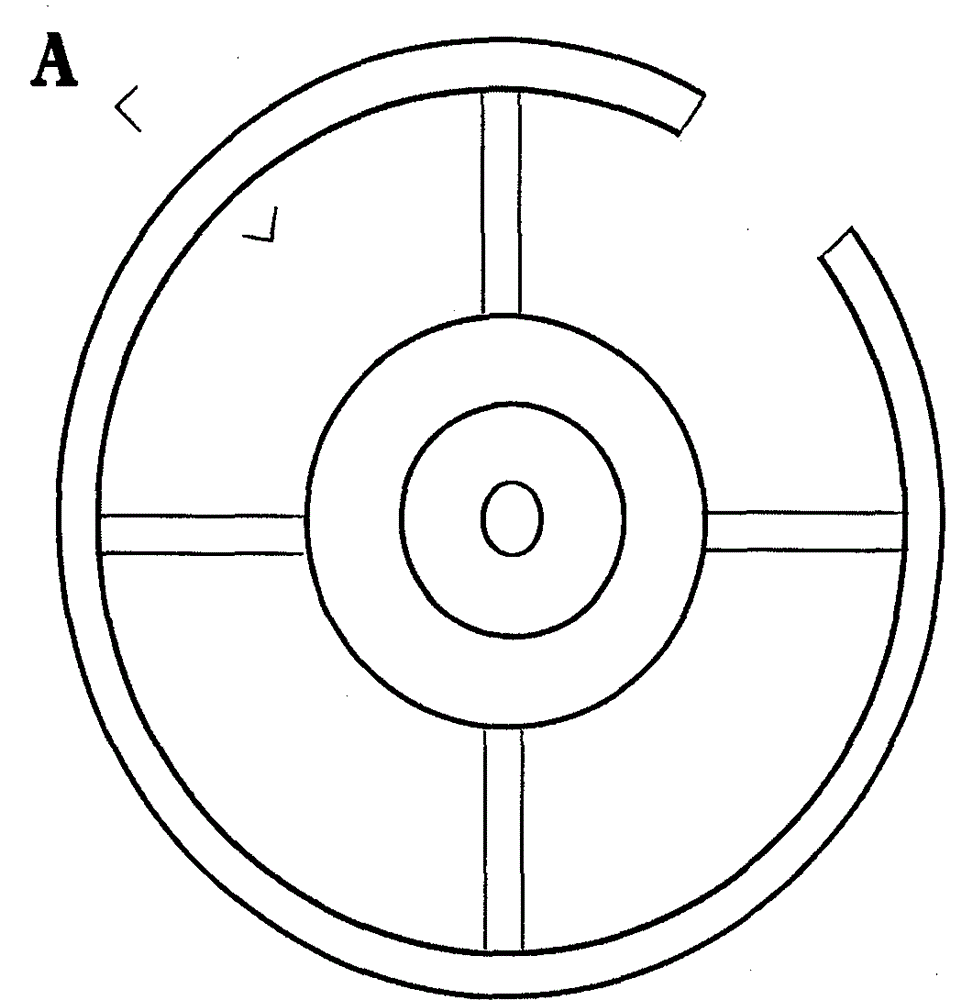

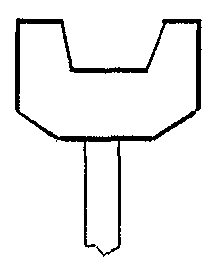

[0012] The wire unloading device of the twisting machine is composed of a rotary bearing support with a rail groove on the outer edge, and a gap is opened on the outer edge of the wheel, and the wire unloading work is completed at one time.

[0013] The working process of the unloading device of stranding machine of the present invention is as follows:

[0014] Put the shaken cable handle on the notch of the rotary support with rail groove on the outer edge, rotate the rotary support one circle, and remove the line easily.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com