Novel continuous beam type rail

A beam-type, new type of technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve problems such as complex construction procedures, prone to falling beams, and prone to cracking, so as to ensure that the alignment is consistent with the design alignment, improve safety and Comfort and the effect of reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

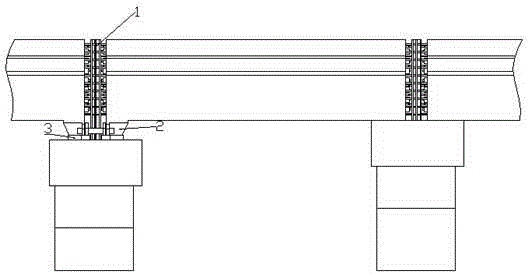

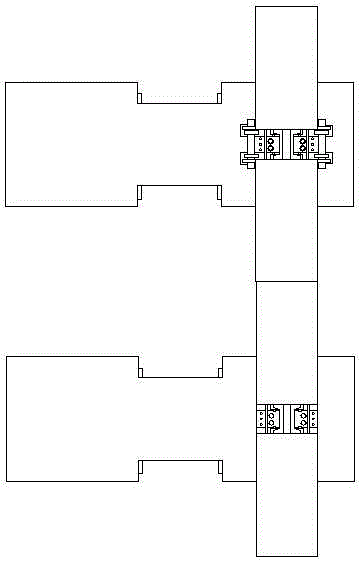

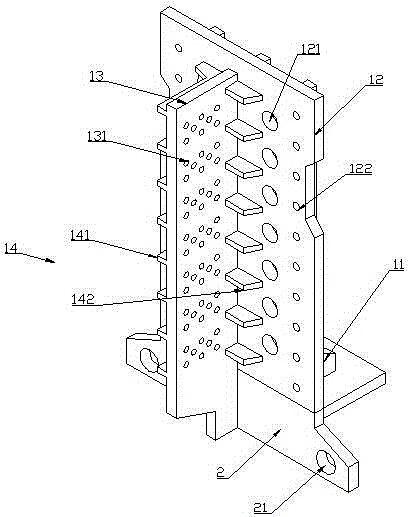

[0031] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown:

[0032] The novel continuous beam track of the present invention comprises a pier column and a track beam fixedly connected with the pier column, and a cover beam is poured on the upper part of the pier column, and a continuous beam includes two side span beams and two side span beams connected with the side span beams respectively. A mid-span beam, the two ends of the mid-span beam are pre-embedded with connecting members 1, and the connecting members 1 are used to connect adjacent track beams and consolidate the track beams on the cover beam; the two ends of the mid-span beam are pre-embedded with A connecting member 1, which is used to connect adjacent track beams and fix the track beams on the cover beam; one end of the side span beam is provided with a connecting member 1, and the connecting member 1 is used to connect adjacent The mid-span track b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com