Dynamic consolidation and drainage construction method for mucky soil

A muddy soil and construction method technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as long construction period, immature dynamic compaction drainage technology, and high water content in muddy soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A construction method for silty soil dynamic compaction drainage, comprising the following steps:

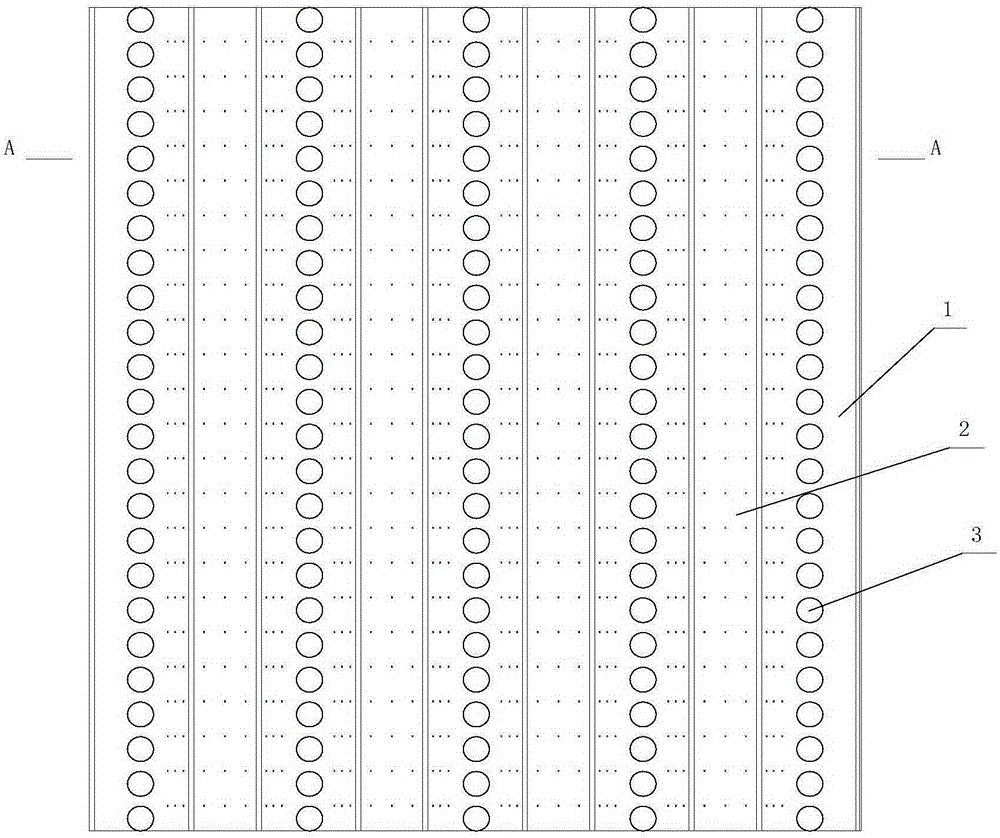

[0029] 1) Determine the dynamic compaction point of the construction area;

[0030] 2) Initial drainage of the ground surface in the construction area;

[0031] 3) Lay a sand cushion on the surface of the construction area;

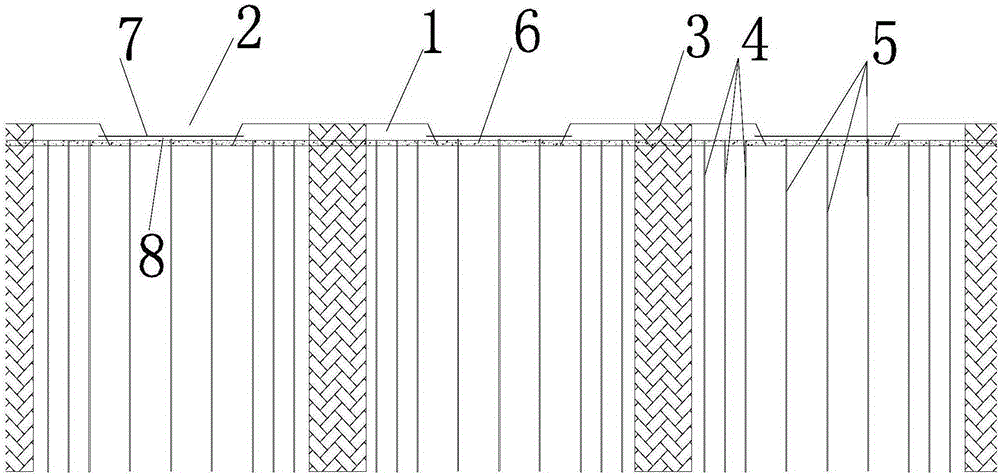

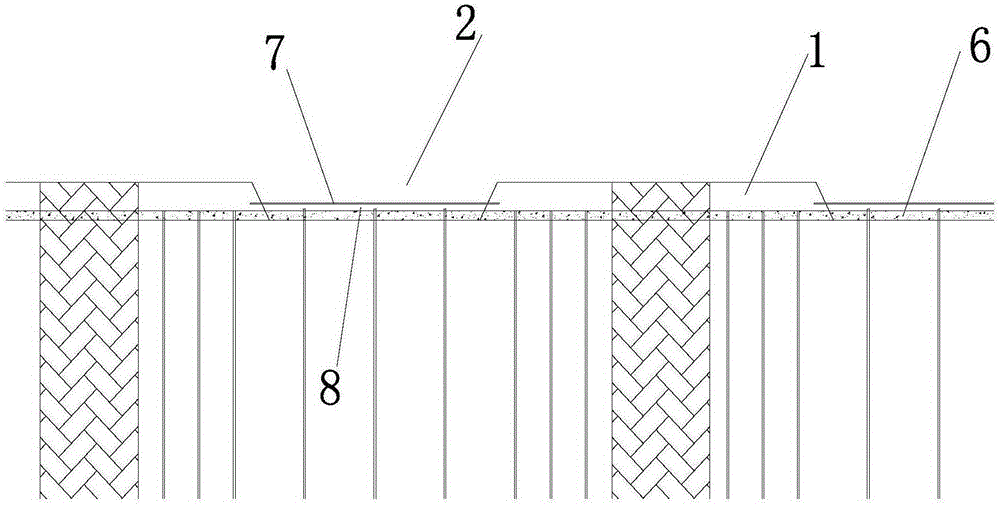

[0032] 4) Install the drainage board;

[0033] 5) Lay another layer of construction channels on the sand cushion above the dynamic compaction point, and the area between adjacent construction channels constitutes a drainage channel;

[0034] 6) Install vacuum drainage equipment in the drainage channel;

[0035] 7) Carry out dynamic compaction construction at the dynamic compaction point of the construction channel according to the drawings;

[0036] 8) After the dynamic compaction construction is completed, the drainage equipment is withdrawn, and the drainage channel area is reinforced.

[0037] In this embodiment, if the high-intensity compact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com