Construction method of fabricated inverted-V-shaped overhanging retaining wall

A construction method, a zigzag technology, applied to artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as complexity, large area occupation, unfavorable quality control and large-scale application, and achieve the effect of reducing earthwork and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

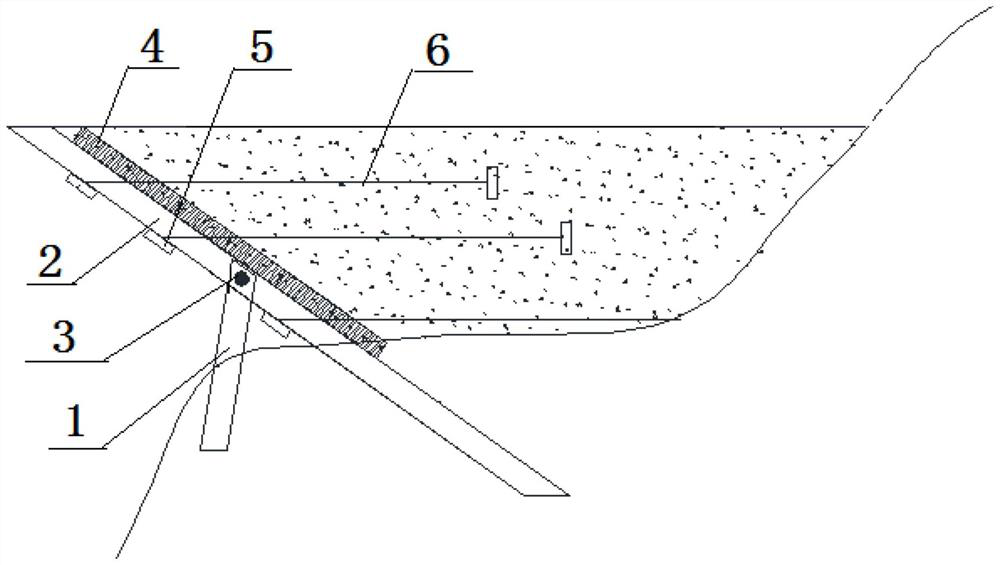

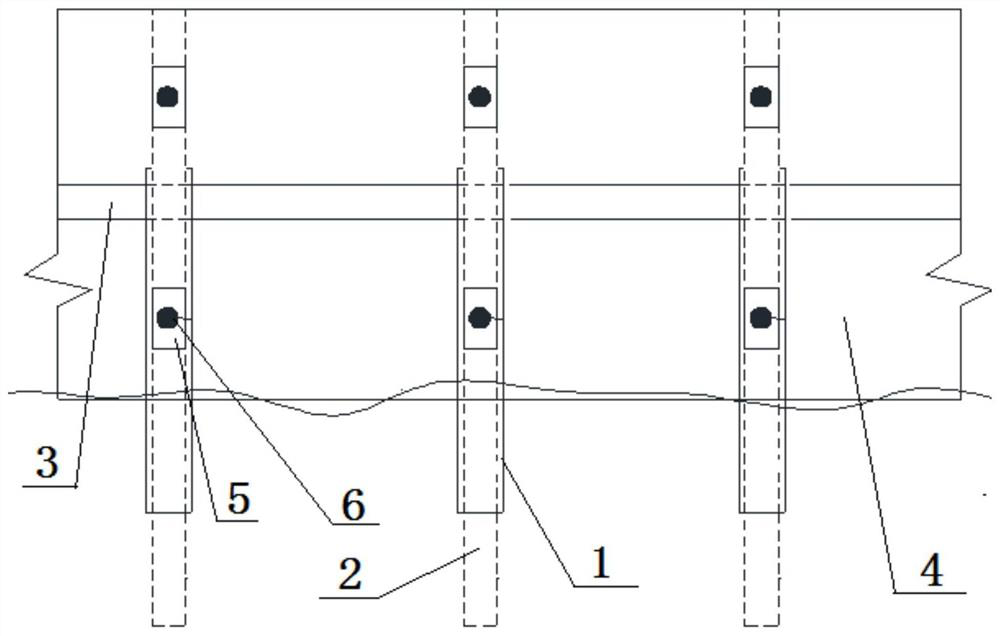

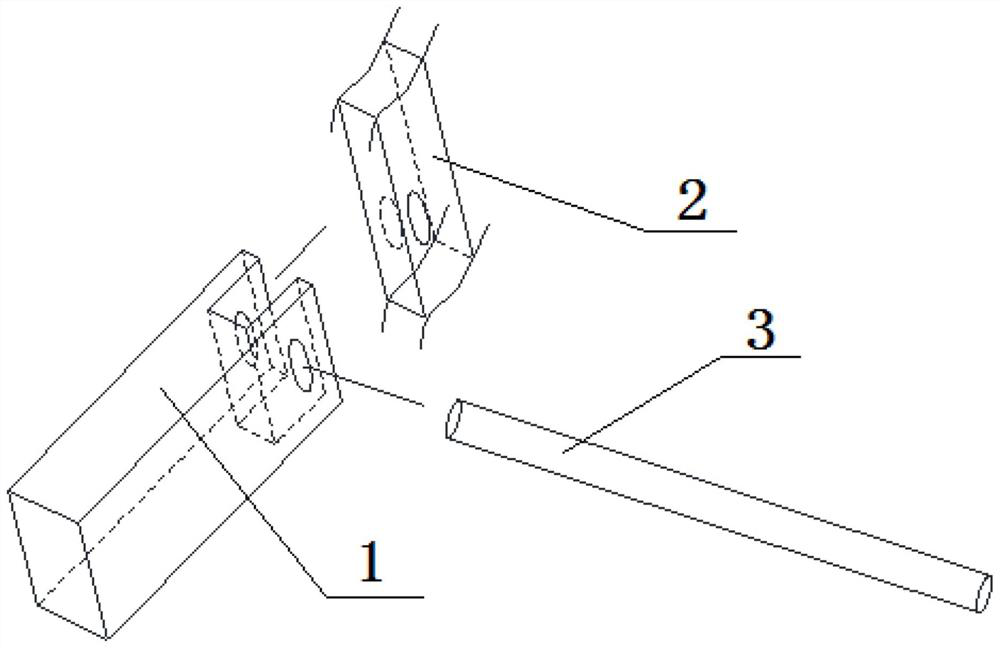

[0032] Example: such as Figure 1 to Figure 3 As shown, a kind of prefabricated Z-shaped cantilever retaining wall also includes a cantilever retaining wall support unit; the cantilever retaining wall support unit includes a Z-shaped support structure and a prefabricated panel 4; the Z-shaped support structure It includes an outer support foot 1, an inner support cantilever beam 2 and a longitudinal fixed beam 3; one end of the outer support foot 1 and one end of the inner support cantilever beam 2 are inserted into the bottom side of the roadbed, and one end of the outer support foot 1 faces the outside of the roadbed , one end of the inner support cantilever beam 2 faces the inner side of the roadbed, and the part where one end of the outer support foot 1 and one end of the inner support cantilever beam 2 is inserted into the bottom side of the roadbed is fixedly connected to the bottom of the roadbed; the outer support foot 1 is in addition One end is flexibly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com