Squeeze-in underground diaphragm wall gapless steering device

An underground diaphragm wall and steering device technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of high cost, affecting the quality of the wall, and poor water-stop effect, so as to save cost and reduce hinge friction. The effect of resistive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

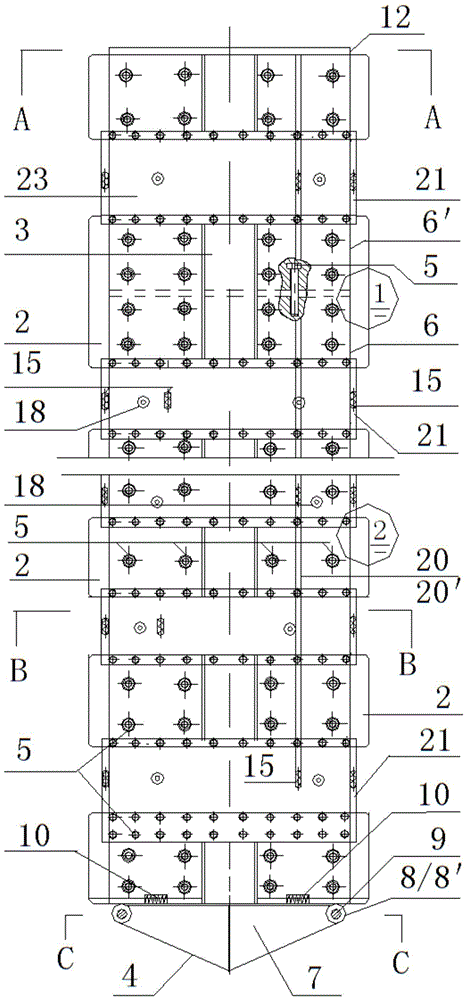

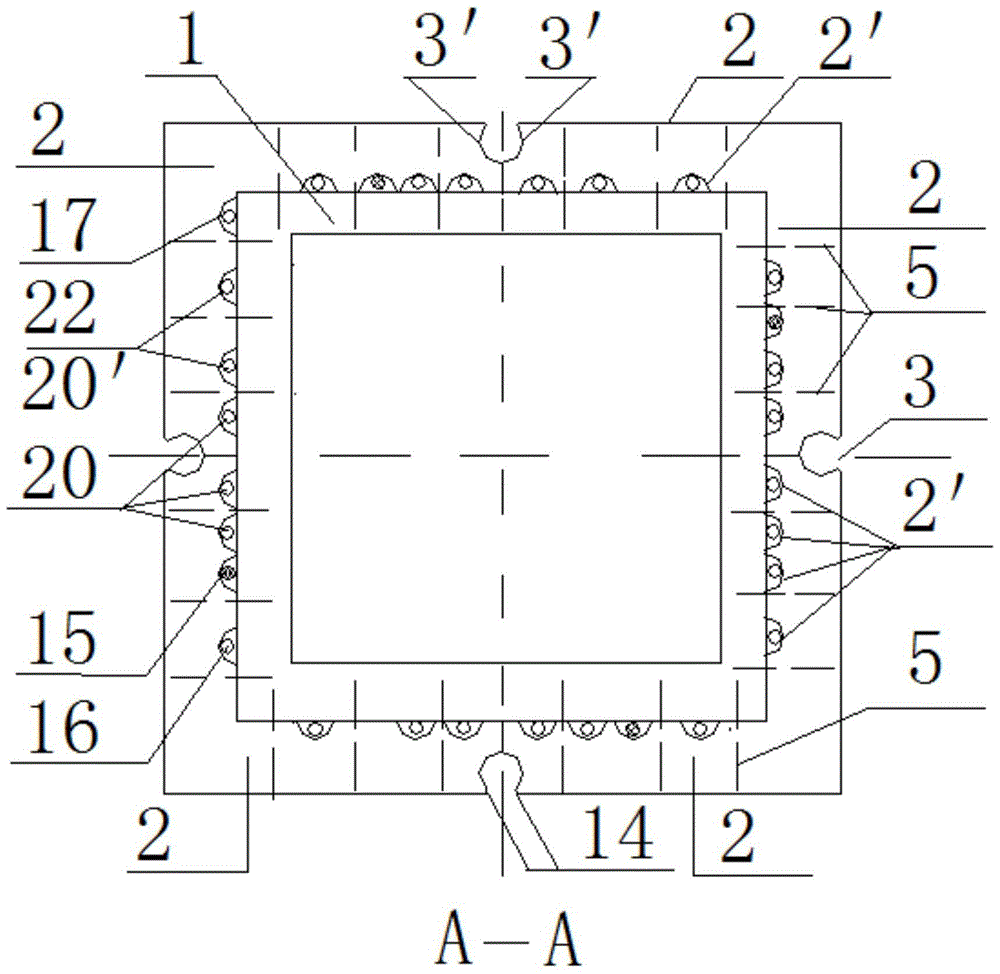

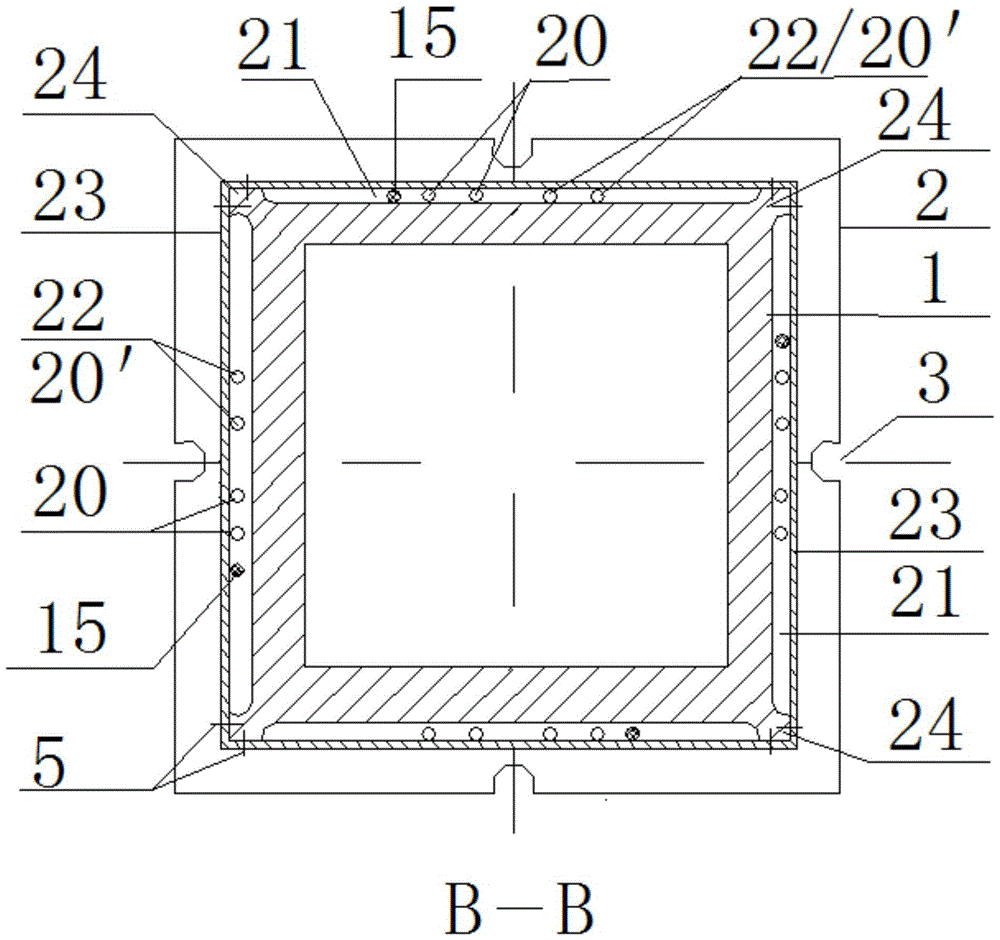

[0033] Such as figure 1 , Figure 6 and Figure 11 As shown, the squeeze-in underground continuous wall gapless steering device of the present invention includes a housing, a vibration cooling device and a rotating device. Such as Figure 1 to Figure 5 As shown, the housing is mainly composed of an inner housing 1, an outer housing 2, a socket 3, and a valve disc. The outer housing 2 is rectangular in shape, and the inner housing 1 is divided into rectangular or circular. In order to meet the requirements of different geometric dimensions of the underground diaphragm wall, the geometric dimensions of the shell are also divided into various specifications. Such as Figure 1 to Figure 3As shown, the rectangular inner shell 1 is a thick-walled hollow rectangular tube with an inner diameter ranging from 200 to 1000 mm and an outer diameter ranging from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com