Direct-drive type high-response axial plunger type variable hydraulic motor with servo motor

A technology of variable motor and servo motor, which is applied in the field of hydraulic variable motor, can solve the problems of not satisfying the output characteristic of hydraulic variable motor, fast response of variable link, slow response of variable link, etc. Ease of machining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

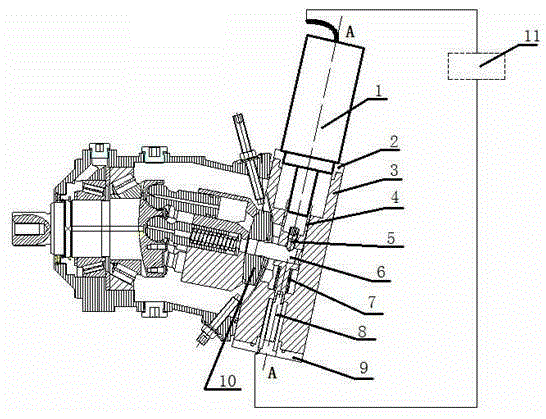

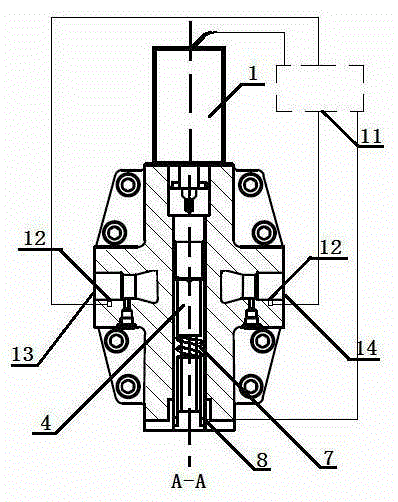

[0019] refer to figure 1 The present invention improves the variable mechanism of the existing axial piston hydraulic variable motor, and removes the internal oil circuit of the variable mechanism of the existing hydraulic variable motor. Specifically, as figure 1 As shown, the variable mechanism of the hydraulic variable motor of the present invention includes a servo motor 1 , a variable control rod 4 , a displacement sensor 8 and a servo drive controller 11 . Wherein, the output end of the servo drive controller 11 is connected with the servo motor 1; the mover of the servo motor 1 is fixedly connected with one end of the variable control rod 4, and the other end of the variable control rod 4 is placed in the chute of the displacement sensor 8 , so that the variable control rod 4 can reciprocate in the chute driven by the servo motor 1 . The displacement sensor 8 is connected to the first signal feedback terminal of the servo drive controller 11 . The displacement sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com