Small load double row angular contact ball bearing with integrated speed change function

A double row angular contact, small load technology, used in rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of complex internal structure of the machine, and achieve fast response, high shear yield stress and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

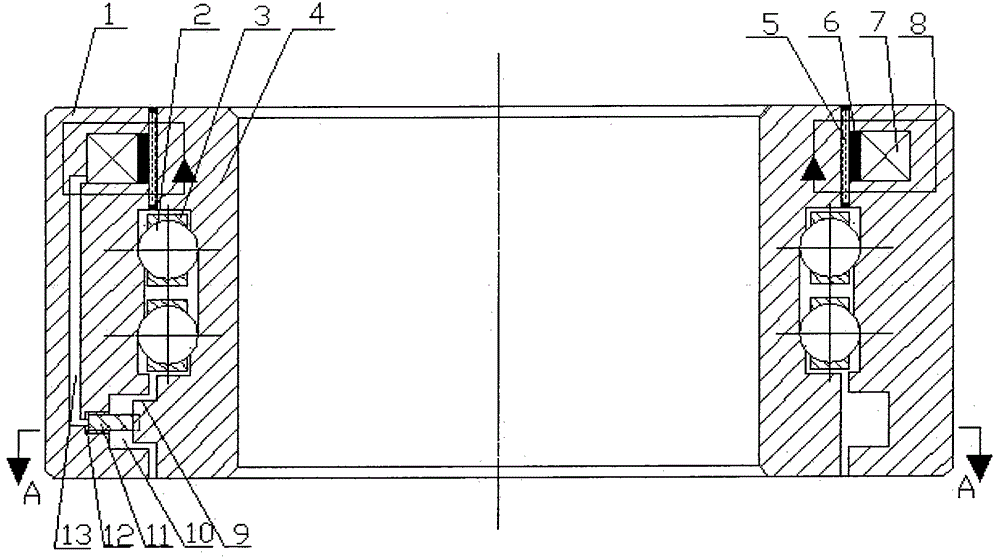

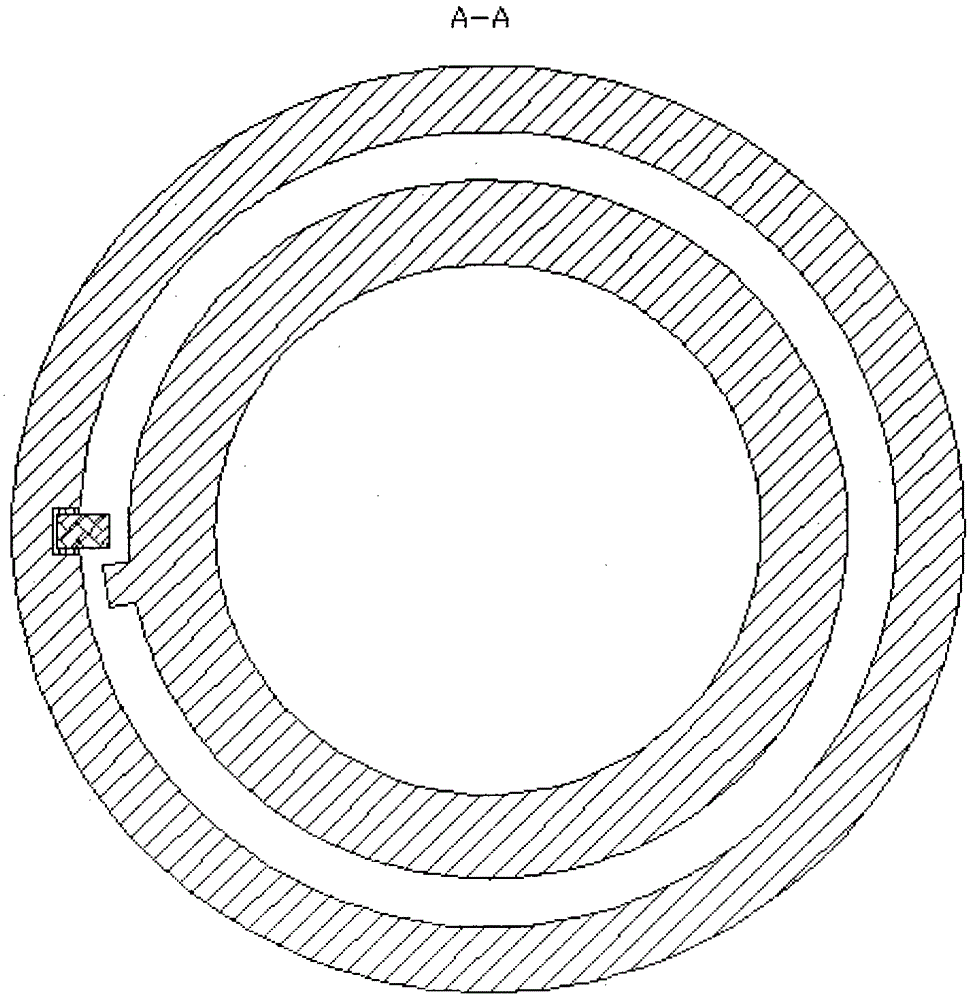

[0010] to combine figure 1 and figure 2 , the present invention is used for a small load double row angular contact ball bearing with integrated speed change function, the device is mainly composed of outer ring 1, rolling element 2, cage 3, inner ring 4, magnetorheological fluid 5, spacer ring 6 , electromagnetic coil 7, piezoelectric ceramics 11, and insulator 12. There are two annular grooves on the inner wall of the outer ring 1, one of which is wound with the electromagnetic coil 7, and the other annular groove 10 is installed with a piezoelectric ceramic 11, and the outer ring 1 is isolated from the piezoelectric ceramic 11 by an insulator 12; The inner ring 1, the outer ring 4 and the isolation ring 6 form a sealed cavity in which the magneto-rheological fluid 5 is sealed, and the magneto-rheological fluid 5 is isolated from the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com