Linear guide rail provided with dustproof structure

A technology of linear guides and dust-proof structure, applied in the field of linear guides, can solve the problems of practical life, dust or pollutants are brought into the belt slide, and the practical accuracy of the linear guides is reduced, so as to achieve low cost and excellent utilization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

[0049] Please refer to figure 1 Shown by:

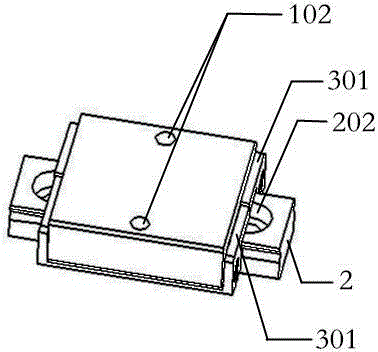

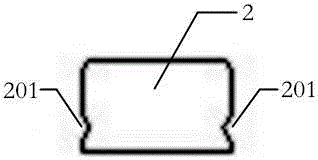

[0050] A linear guide rail with a dust-proof structure proposed by the present invention includes a sliding seat 1 , a guide rail 2 , a dust-proof structure 3 and a rolling structure 4 .

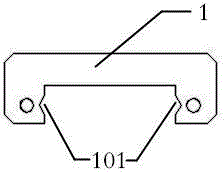

[0051] Specifically, the sliding seat 1 is a rectangular metal sheet with a U-shaped cross-section and a thickness. Grooves 101 are symmetrically arranged on the two inner surfaces of the sliding seat 1 along the moving direction of the linear guide rail. , the upper surface of the sliding seat 1 is provided with an external interface 102 for connecting the external workpiece to be connected, the setting of such an external interface 102 can be matched and reasonably set according to actual needs;

[0052] As a preferred solution of the linear guide rail of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com