Single-piston stroke inductive type resistance change damping structure

A technology of stroke induction and resistance change, which is applied in the direction of springs, shock absorbers, spring/shock absorbers, etc., can solve the problems of limited range of use, high cost, difficulty in debugging and maintenance, and achieve the effect of variable damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

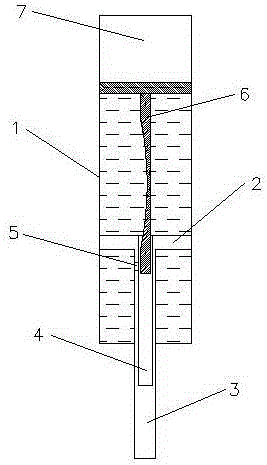

[0022] Embodiment 1: Single-piston stroke-inductive resistance change damping structure (see attached figure 1 ), including a cylinder 1, a piston 2 is arranged in the cylinder 1, a piston rod 3 is arranged in the piston 2, a through hole 4 with an opening 5 is arranged on the piston rod 3, and the through hole 4 A variable-diameter damping rod 6 is arranged inside, the length of the variable-diameter damping rod 6 is greater than the depth of the through hole 4, the diameter of the variable-diameter damping rod 6 gradually changes through a smooth arc, and the upper end of the cylinder 1 is provided with a seal The air chamber 7, the air-sealed chamber 7 is fixedly connected with the cylinder body 1 .

[0023] The smooth arc of the damping rod is excessive and gradual, so that the damping changes smoothly and the stability is high. By changing the gap between the variable-diameter damping rod arranged in the through hole and the through hole and the opening on the through hol...

Embodiment 2

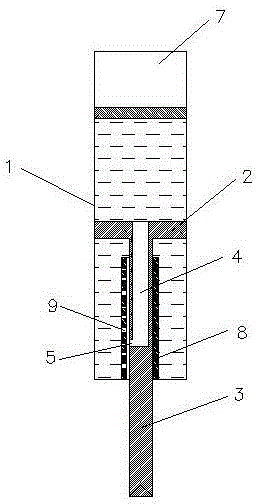

[0024] Embodiment 2: Single-piston stroke-inductive resistance change damping structure (see attached figure 2 ), including a cylinder body 1, a piston 2 is arranged in the cylinder body 1, a piston rod 3 is arranged in the piston 2, a through hole 4 with an opening 5 is arranged on the piston rod 3, and a 3. A variable damping outer tube 8 is provided. The variable damping outer tube 8 is sleeved on the outside of the piston rod 3. The variable damping outer tube 8 is fixedly connected to the cylinder body 1. The variable damping outer tube 8 is provided with a row of damping holes 9, the distance between the damping holes 9 is smaller than the maximum diameter of the opening 5, the damping holes 9 are arranged longitudinally on the variable damping outer tube 8, and the upper end of the cylinder 1 is provided with a gas seal Cavity 7, the air-sealed cavity 7 is fixedly connected with the cylinder body 1.

[0025] By changing the positions of the damping hole and the upper ...

Embodiment 3

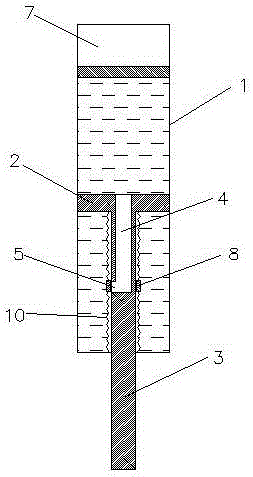

[0027] Embodiment 3: Single-piston stroke-inductive resistance change damping structure (see attached image 3 ), including a cylinder 1, a piston 2 is arranged in the cylinder 1, a piston rod 3 is arranged in the piston 2, a through hole 4 with an opening 5 is arranged on the piston rod 3, and the variable damping Both ends of the outer tube 8 are provided with damping springs 10, the damping spring 10 at the upper end of the variable damping outer tube 8 is fixedly connected with the piston 3, and the damping spring 10 at the lower end of the variable damping outer tube 8 is fixed to the cylinder body 1 Connection, the length of the variable damping outer tube 8 is greater than or equal to the maximum diameter of the opening 5, the upper end of the cylinder 1 is provided with an air sealing chamber 7, and the air sealing chamber 7 is fixedly connected with the cylinder 1.

[0028] When the piston compresses and moves, the relative position of the variable damping outer tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com