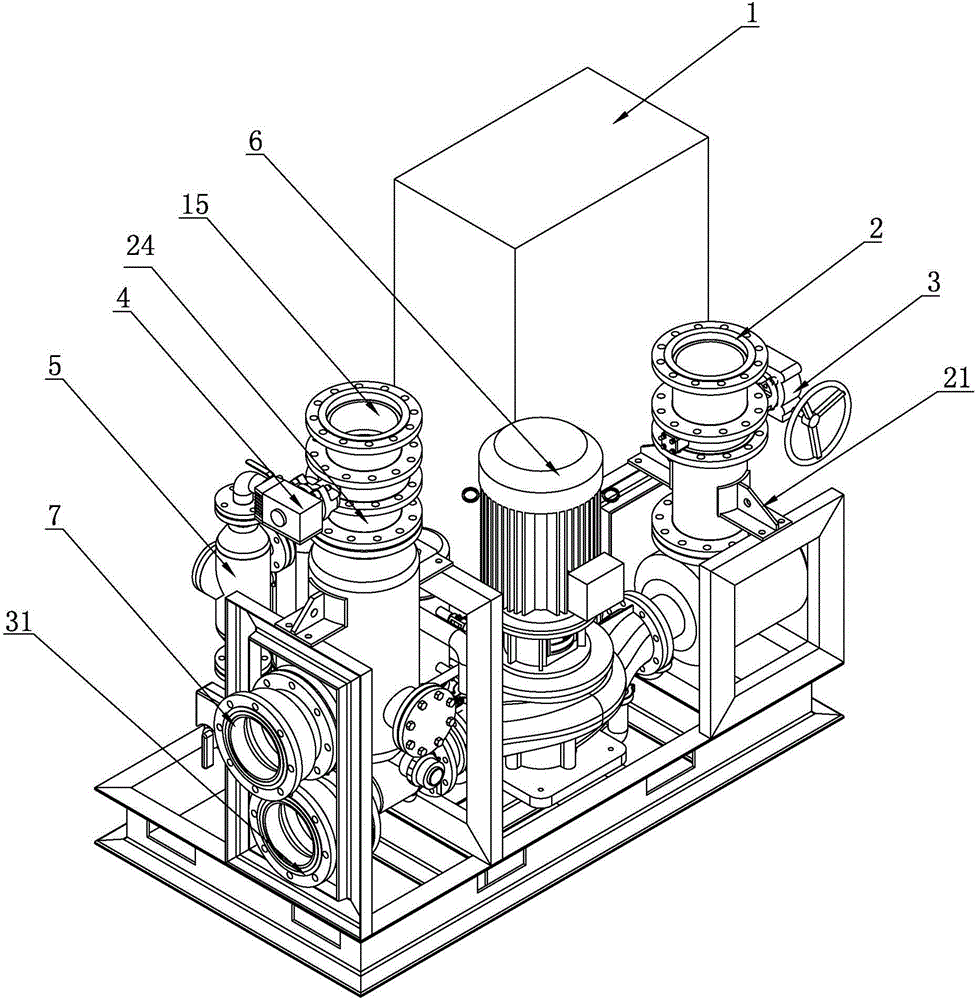

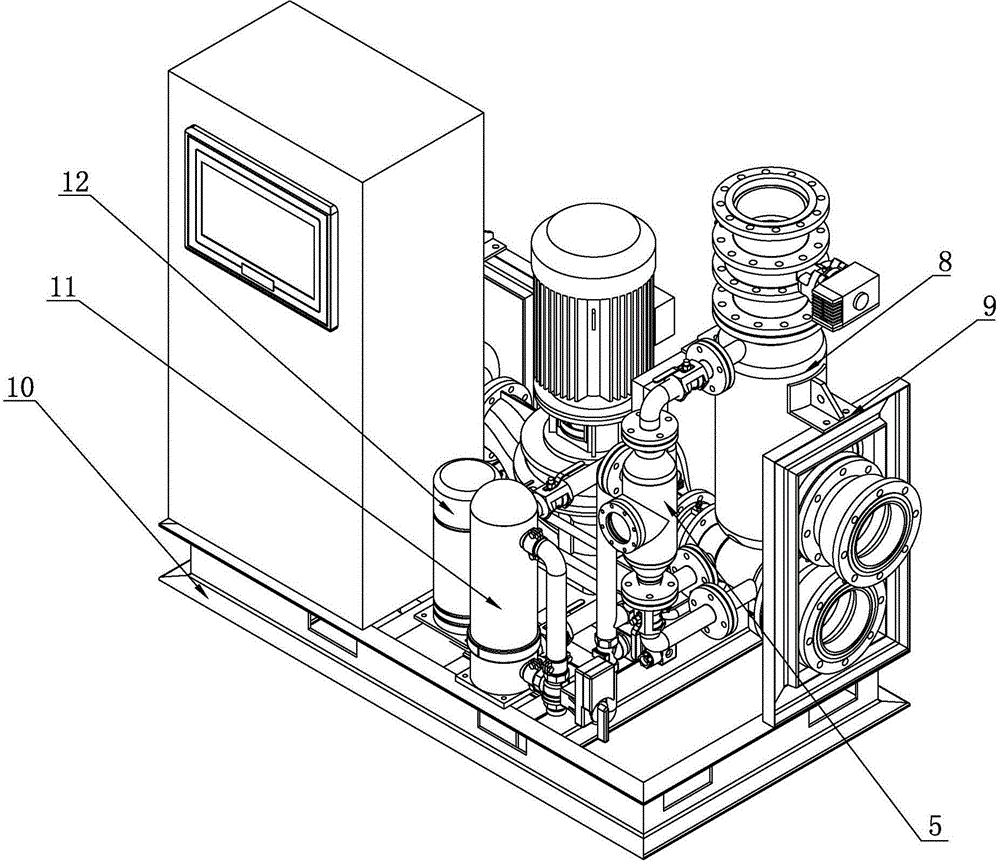

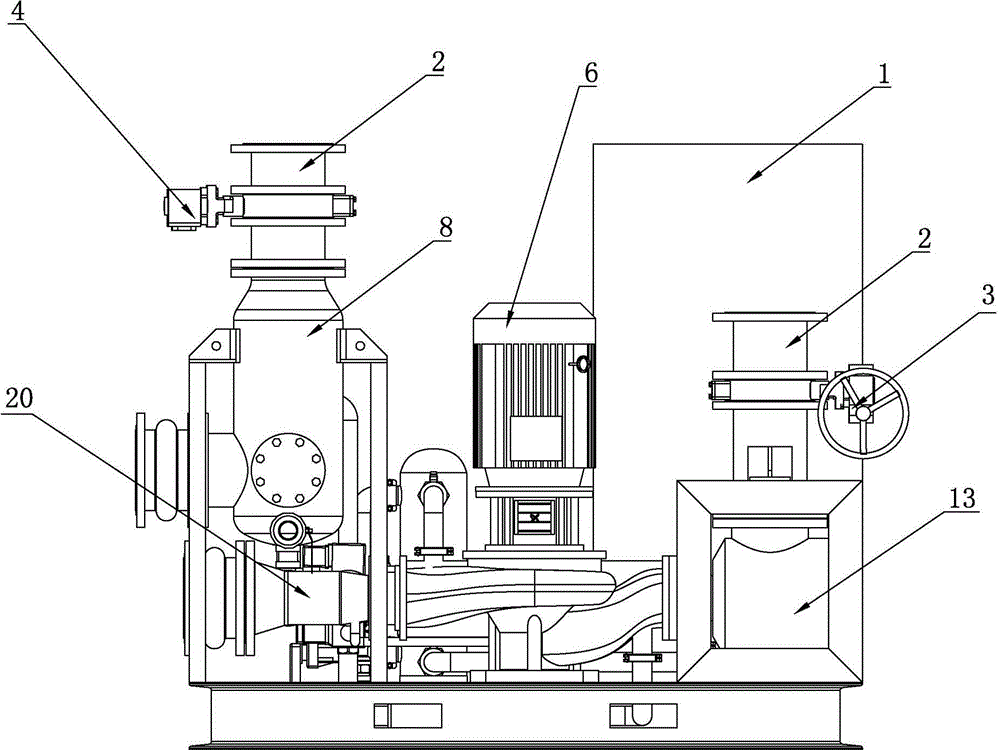

Workstation of water-cooling chilling unit water system

A technology of water chillers and workstations, which is applied to household refrigeration devices, lighting and heating equipment, and cleaning of non-rotating equipment. It can solve problems such as inconvenient operation and maintenance, increased coordination work, and complicated manual work, and achieves floor space and material savings. Consumption, reduce system energy consumption, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

[0032] Please see attached figure 1 To attach Image 6 , the bottom of the present invention is a shock-absorbing base 10, which is convenient for the installation of the present invention, and can play a shock-absorbing effect during the operation of subsequent equipment. The circulating water pump 6 is fixed on the shock-absorbing base 10, and the circulating water pump The water inlet side of 6 is connected to the water outlet end of the collecting and distributing filter 13, and the collecting and distributing filter 13 can coarsely filter impurities in the circulating water of the system. Refers to a plate with punching holes, the ratio of the punching area to the entire plate area is the punching rate, for the filter, the punching rate mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com