Heat radiating turbulence tube

A technology of turbulent flow pipes and pipes, applied in the field of vehicle radiators, which can solve the problems of increasing engine heat dissipation and affecting radiator resistance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

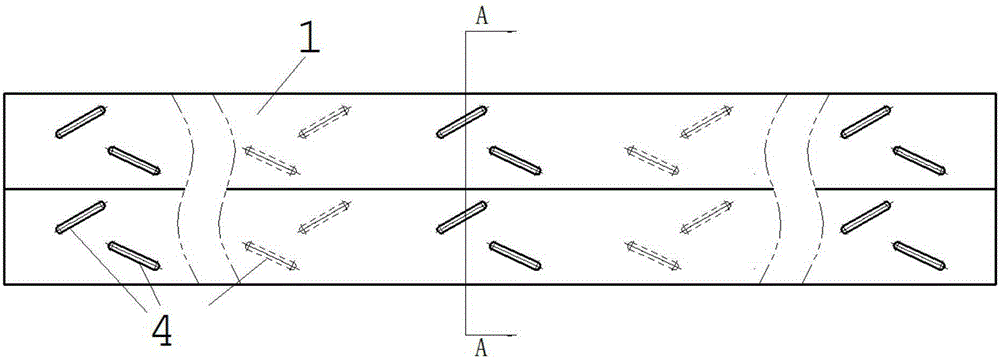

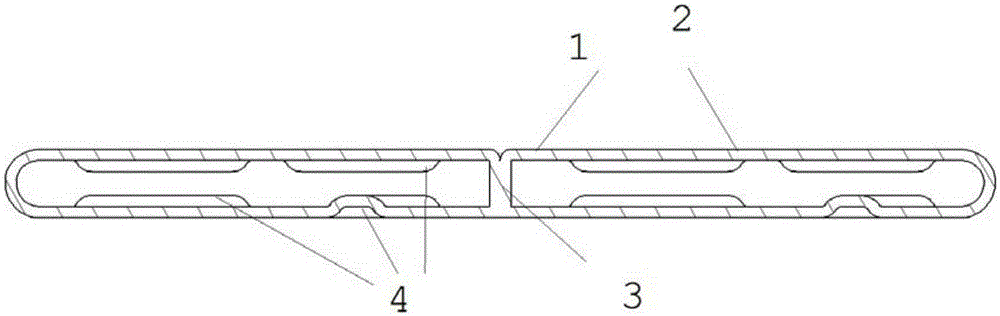

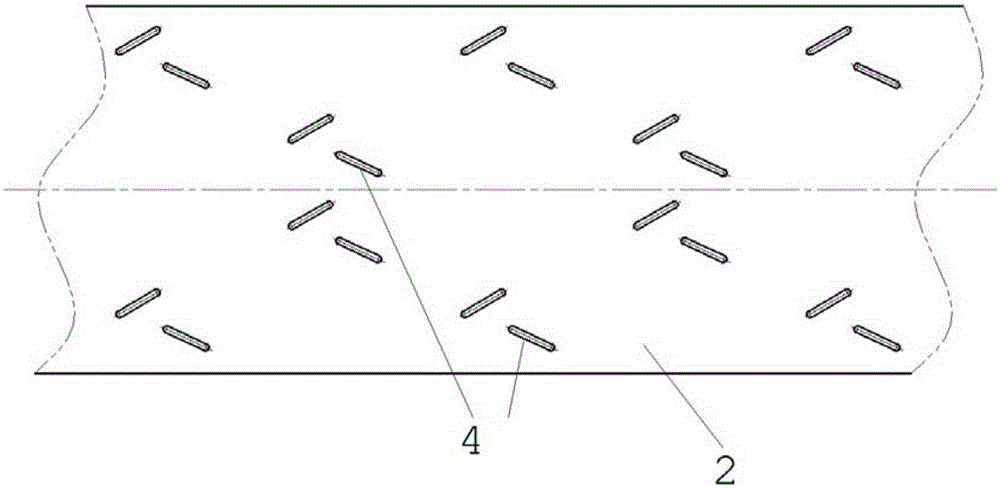

[0018] Figure 1-4 It is an embodiment of the heat dissipation turbulent flow tube implemented according to the present invention. The heat dissipation turbulent pipe 1 is a long pipe with a flat pipe; it is characterized in that: a vertical partition 3 is arranged at the center line of the flat pipe, and the vertical partition 3 is connected with the upper wall and the lower wall 2 in the horizontal direction to isolate the pipe into two parts. The same cavity; the upper wall and the lower wall 2 are provided with discrete array convex strips 4; the same convex strip 4 is recessed relative to the outer wall surface of the respective wall (upper wall or lower wall 2), and relative to the respective The inner wall surface of the wall surface (upper wall or lower wall 2) is convex.

[0019] Further, the protruding lines 4 are distributed in groups of spaced arrays on the walls where they are respectively located, and the two protruding lines of each group are arranged in a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com