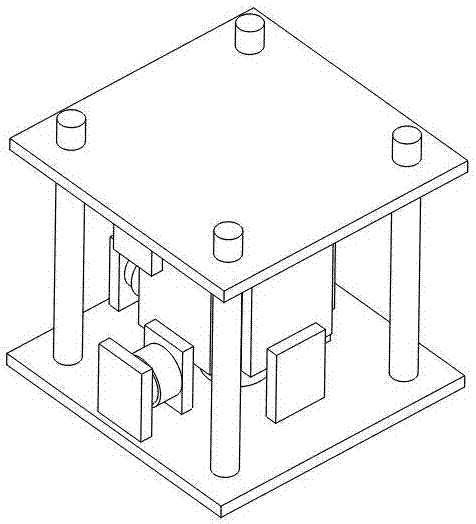

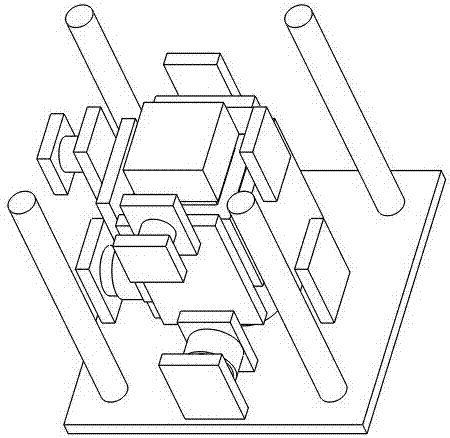

A rock true triaxial test system and method with CT real-time scanning system

A test system and scanning system technology, applied in the field of rock true triaxial test system, can solve problems such as not being able to represent rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

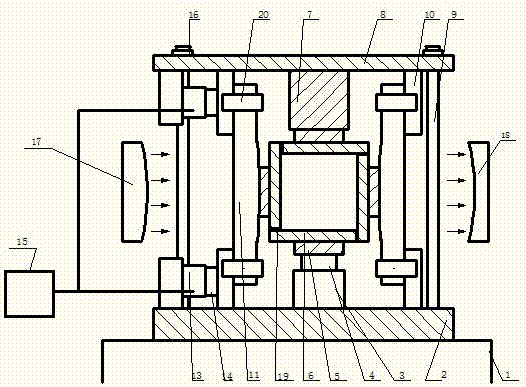

[0051] Step 1: first fix the bottom plate 2 on the base 1, cover the ends of the four carbon fiber columns 9 with metal sleeves 16, and bond them with epoxy structural adhesive 21 to enhance the compression and shear resistance of the ends of the columns 9 , the metal sleeves 16 are respectively fixed on the bottom plate 2 and the top plate 8, and the vertical spacer 7 is welded and fixed on the bottom of the top plate 8; the bottom plate 2, the top plate 8 and the vertical spacer 7 are all made of Q460 high-strength steel, and the four columns 9 are made of High tensile strength carbon fiber (T800) material;

[0052] Step 2: Fix the vertical electric jack 3 on the bottom plate 2, and fix the vertical measuring device 4 on the vertical electric jack 3;

[0053] Step 3: Weld and fix one of the lateral reaction walls 10 located at the front, rear and left and right to the top plate 8 and the bottom plate 2 respectively, and set the lateral reaction wall 10 on the other side as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com