Optical cable dynamic friction coefficient test device and method

A technology for the coefficient of kinetic friction and testing equipment, which is used in measuring devices, instruments, and mechanical devices, etc. It can solve the problems of not being able to make more detailed plans for optical cables through pipes, users not being able to accurately know the optical cables, and unable to refer to the coefficient of kinetic friction. Accurate parameters, accurate coefficient of kinetic friction and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

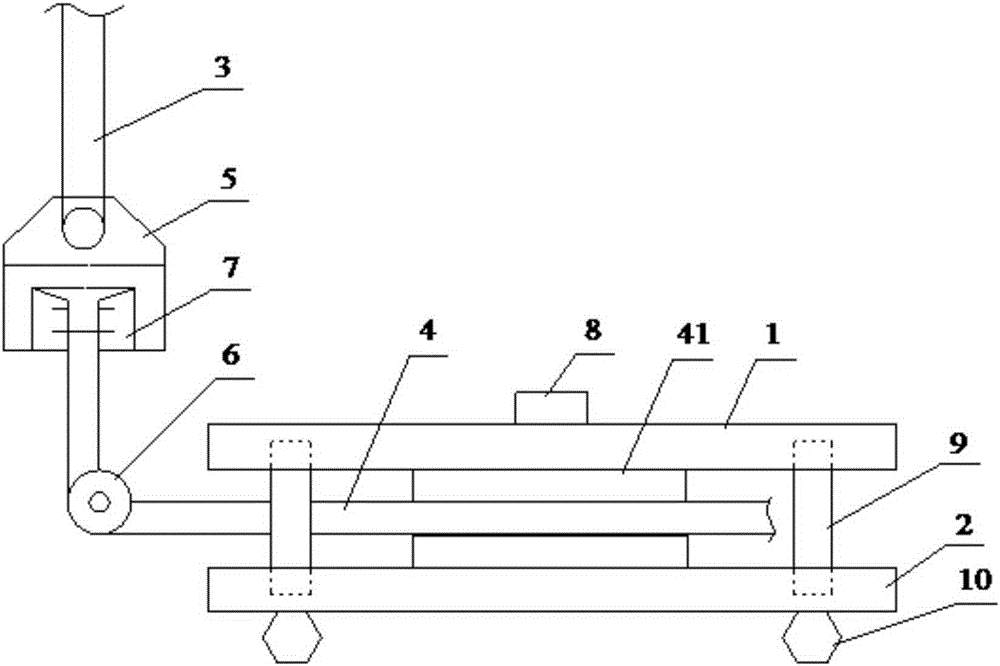

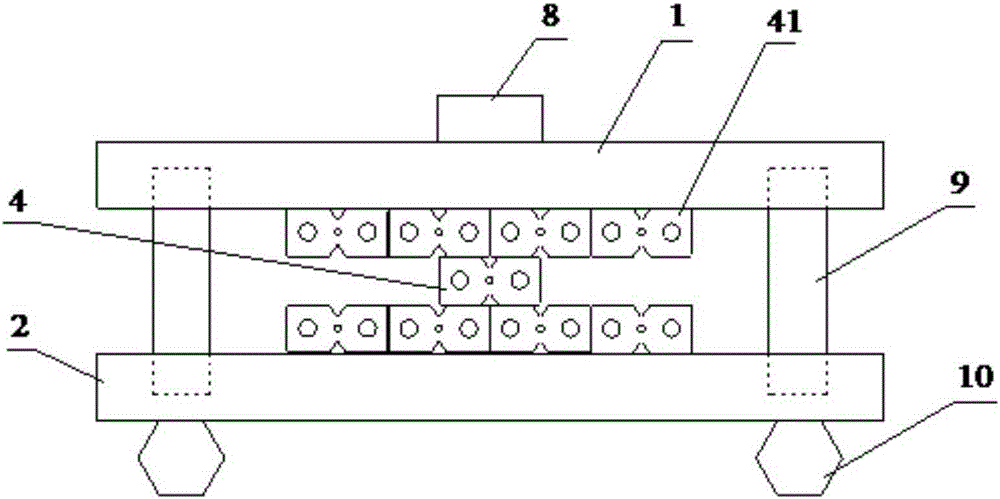

[0025] Such as figure 1 As shown, the optical cable dynamic friction coefficient testing equipment of the present invention comprises an upper steel plate 1 and a lower steel plate 2, and the four corners of the top surface of the lower steel plate 2 are respectively provided with concave holes, and each concave hole is inserted with a support rod 9, and the upper steel plate 1 The four corners of the bottom surface are also provided with concave holes, which are used to accommodate the top of each support rod. Therefore, the upper steel plate 1 and the lower steel plate 2 are supported by the support rod 9, and the four corners of the bottom surface of the lower steel plate 2 are respectively provided with A pad 10 of the same height ensures that the stainless steel plate does not tilt. An optical cable 4 to be tested is arranged horizontall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com